Preparation method of low-potassium low-sodium low-chloride high-purity ammonium paratungstate

A pure ammonium paratungstate and sodium tungstate technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problem of high corrosion of furnace tubes, unfavorable control of crystal form and morphology of cemented carbide, affecting equipment service life, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

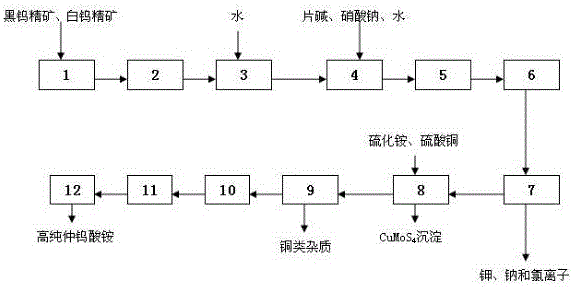

[0026] The process of a high-purity ammonium paratungstate preparation method of the present invention includes ore blending and ball milling, alkali boiling decomposition, ion exchange, molybdenum removal, crystallization and drying processes to obtain high-purity ammonium paratungstate. The steps are as follows:

[0027] ⑴Mine blending and ball milling

[0028] The control of black tungsten concentrate, scheelite concentrate and black and white tungsten mixed concentrate in tungsten concentrate contains less than 10% calcium in the ore blending. Ball mill the tungsten concentrate after blending, and add quantitative tap water at the same time to control the grinding particle size -325 mesh greater than 95%.

[0029] ⑵Alkali boiling decomposition

[0030] Add a certain amount of caustic soda, sodium nitrate and water to the pulp that has been ground in step (1) to form a slurry, and then decompose it with alkali to obtain a crude sodium tungstate slurry; the crude sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com