Synthesis method of supported MoS2 catalyst

A synthesis method and catalyst technology, which is applied in the field of MoS2 catalyst synthesis, can solve the problems of imperfect preparation methods of multi-stage molecular sieves, and achieve the effects of low synthesis cost, strong process economy, and safe and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

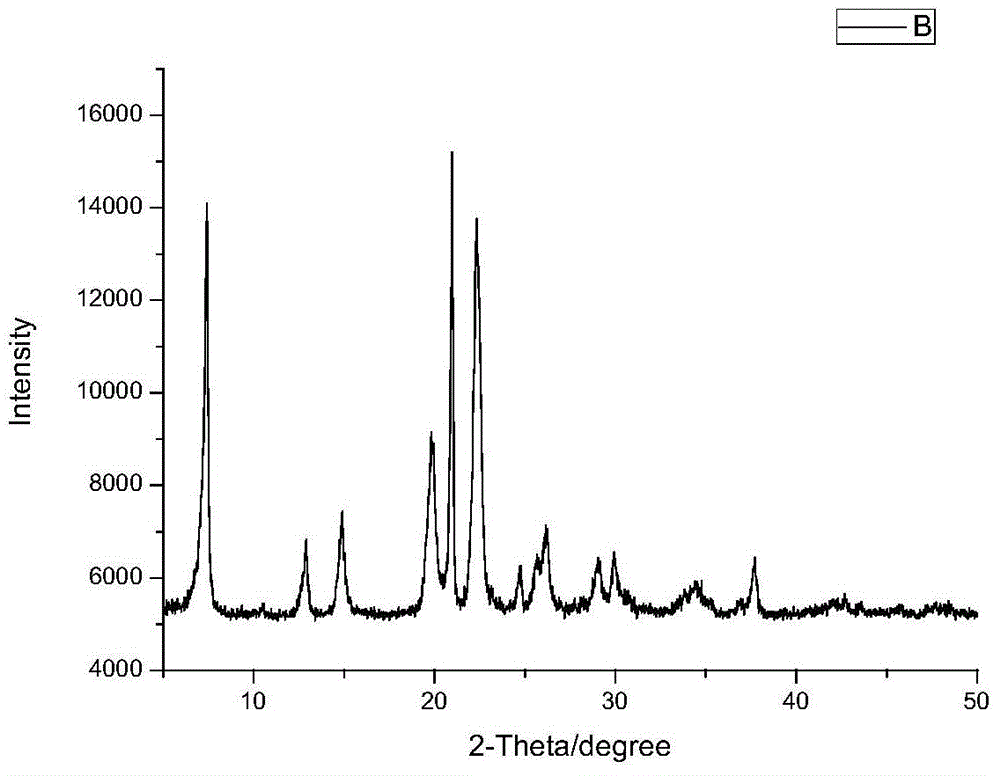

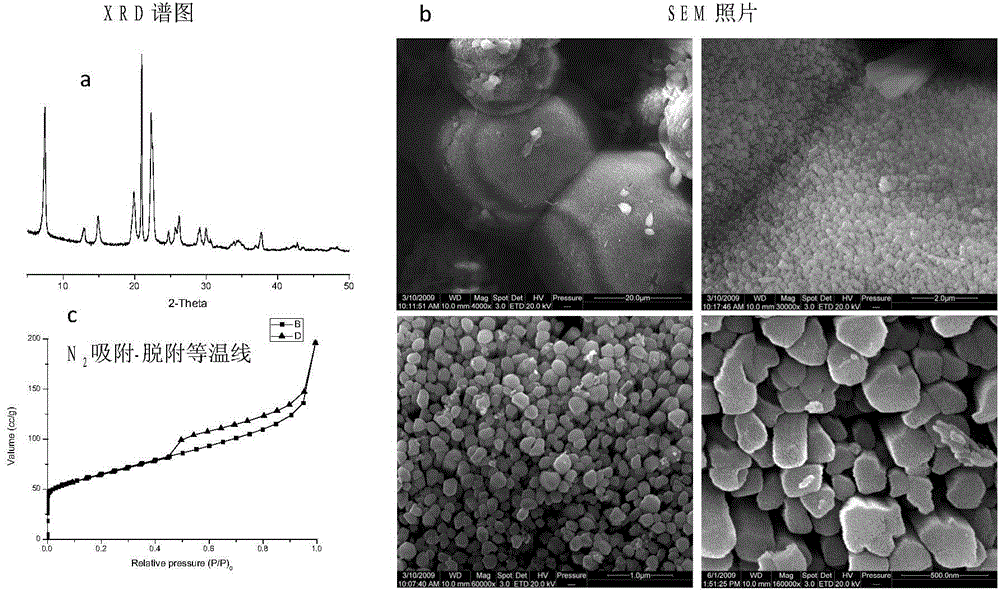

[0024] At 80°C, 1.5 g of phosphoric acid, 0.88 g of aluminum isopropoxide, 0.4 g of ethanolamine and 0.05 g of hydrofluoric acid with a mass concentration of 40% were added to 33 g of 1-butyl-3-methylimidazolium bromide ionic liquid and mixed , and stir until a homogeneous precursor mixture is obtained. The above mixture was transferred to a stainless steel reaction kettle with a polytetrafluoroethylene lining, and then placed in an oven at 150°C for crystallization. After crystallization for 6 hours, it was taken out, the reaction kettle was cooled, and then 200ml of deionized water was added to the reaction mixture. After ultrasonic washing, the reactant was filtered to obtain a white solid, which was repeatedly washed three times with deionized water and washed with 50 ml of ethanol. The final white solid was dried in an oven at 110°C to finally obtain a white powdery solid, which was determined by XRD, as figure 1 As shown, characteristic diffraction peaks with 2θ angles...

Embodiment 2

[0026] At 80°C, 1.8 g of phosphoric acid, 1.0 g of aluminum isopropoxide, 0.5 g of ethanolamine and 0.05 g of hydrofluoric acid with a mass concentration of 40% were added to 20 g of 1-butyl-3-methyl imidazolium bromide ionic liquid and mixed , and stir until a homogeneous precursor mixture is obtained. The above mixture was transferred to a stainless steel reactor with a polytetrafluoroethylene lining, and then placed in an oven at 160°C for crystallization. After crystallization for 4 hours, it was taken out, the reactor was cooled, and then 300ml of deionized water was added to the reaction mixture. After ultrasonic washing, the reactant was filtered to obtain a white solid, which was repeatedly washed three times with deionized water and washed with 50 ml of ethanol. The final white solid was dried in an oven at 110°C, and finally a white powdery solid was obtained, which was determined by XRD test, as figure 2 As shown, the characteristic diffraction peaks with 2θ angle...

Embodiment 3

[0028] 0.5 ml of ammonium tetrathiomolybdate solution with a concentration of 0.01 g / ml was impregnated on 0.4 g of the hierarchical porous AFI molecular sieve carrier synthesized in Example 2. The impregnated catalyst was air-dried at room temperature, and then transferred to a vacuum oven at 70°C for 4 hours. The dried catalyst was placed in a tube furnace under N 2 Under the condition of purging, the temperature was raised to 450°C and kept for 8 hours to prepare MoS supported by multi-level porous AFI molecular sieves. 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com