Production system of desulfurization product magnesium sulfate regenerative desulfurization adsorbent magnesium hydroxide

A technology of magnesium hydroxide and magnesium sulfate, applied in the direction of magnesium hydroxide, etc., can solve the problems such as the shadowed prospect of magnesium desulfurization, the large amount of magnesium sulfate produced by desulfurization, and the high difficulty of market digestion, so as to achieve convenient operation and maintenance, reduce heat energy, The effect of reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

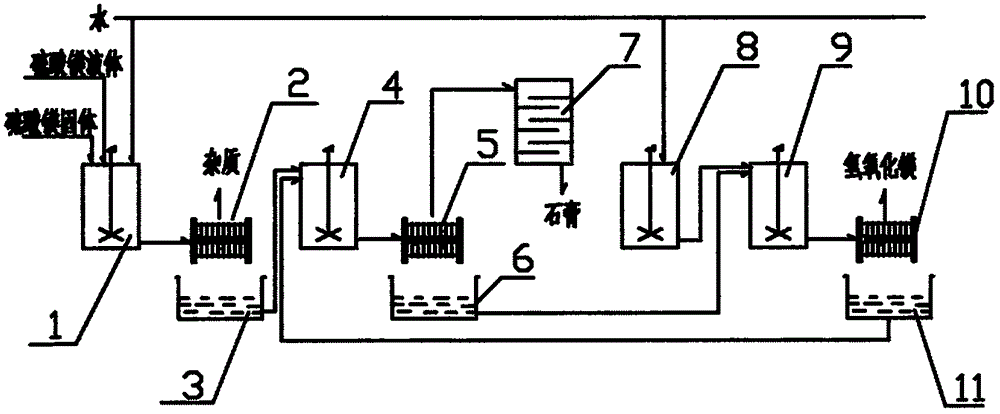

[0024] Such as figure 1 Shown, a kind of production system of desulfurization product magnesium sulfate regeneration desulfurization agent magnesium hydroxide comprises, magnesium sulfate pulper 1, magnesium sulfate filter 2, magnesium sulfate storage tank 3, gypsum precipitation reactor 4, gypsum filter 5. Magnesium chloride liquid storage tank 6, gypsum drying calciner 7, dolomite lime feeder 8, calcium and magnesium separation reactor 9, magnesium hydroxide filter 10, calcium chloride liquid storage tank 11, characterized in that: magnesium sulfate adjustment The slurry outlet of slurry device 1 is connected to the slurry inlet of magnesium sulfate filter 2, the filtrate outlet of magnesium sulfate filter 2 is connected to the inlet of magnesium sulfate storage tank 3, and the filtrate outlet of magnesium sulfate storage tank 3 is connected to the raw material inlet of gypsum precipitation reactor 4 Connected, calcium chloride storage tank 11 liquid (comprising filtrate and...

Embodiment 2

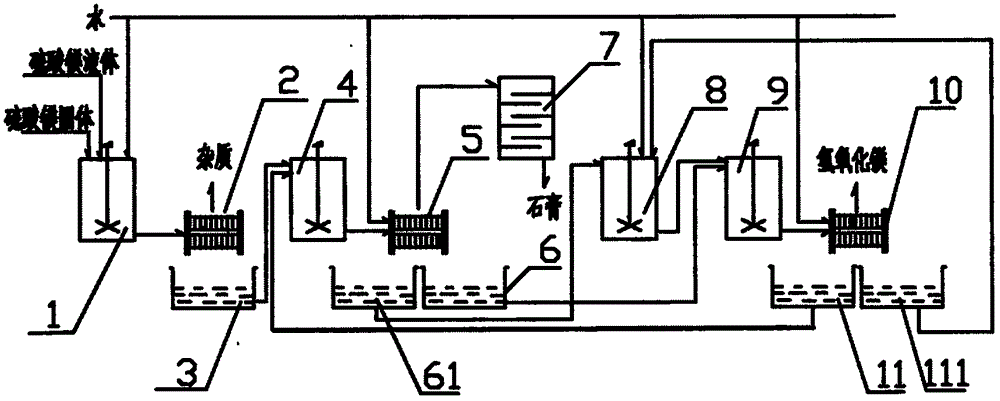

[0032] Such as figure 2 Shown, a kind of production system of desulfurization product magnesium sulfate regeneration desulfurization agent magnesium hydroxide comprises, magnesium sulfate pulper 1, magnesium sulfate filter 2, magnesium sulfate storage tank 3, gypsum precipitation reactor 4, gypsum filter 5. Magnesium chloride storage tank 6, magnesium chloride lotion storage tank 61, gypsum drying calciner 7, dolomite lime feeder 8, calcium and magnesium separation reactor 9, magnesium hydroxide filter 10, calcium chloride storage tank 11, The calcium chloride lotion storage tank 111 is characterized in that: the slurry outlet of the magnesium sulfate slurryer 1 is connected to the slurry inlet of the magnesium sulfate filter 2, and the filtrate outlet of the magnesium sulfate filter 2 is connected to the inlet of the magnesium sulfate storage tank 3, The filtrate outlet of the magnesium sulfate storage tank 3 communicates with the raw material inlet of the gypsum precipitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com