Bentonite composite material for treating high-zinc and copper cyaniding wastewater and application of bentonite composite material

A composite material and cyanide wastewater technology, which is applied in energy wastewater treatment, physical/chemical process catalysts, water pollutants, etc., can solve the problems of low solar energy utilization rate and not widely used titanium dioxide, and meet the requirements of loose reaction conditions, Ease of operation and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Add butyl titanate, absolute ethanol, and concentrated nitric acid into a three-necked flask, stir for 30 minutes, and mix well to obtain mixture A; wherein the volume ratio of butyl titanate, absolute ethanol, and concentrated nitric acid is 20:40 :1;

[0037] (2) Dissolve lanthanum nitrate hexahydrate in deionized water, add concentrated nitric acid and mix evenly, then add absolute ethanol and mix evenly to obtain mixture B; the volume ratio of deionized water, concentrated nitric acid, and absolute ethanol is 5:0.5 :20; the mol ratio of La and Ti is 1:100 in step (2); the mass ratio of lanthanum and deionized water is 24:1000.

[0038] (3) Under the stirring condition of 200rpm, the mixture B was added dropwise to the mixture A at a rate of 1 drop / second to obtain the mixture C. After the addition was completed, the mixture C was continued to be stirred for 30 minutes to obtain a milky white liquid;

[0039] (4) add bentonite to the milky white liquid that step...

Embodiment 2

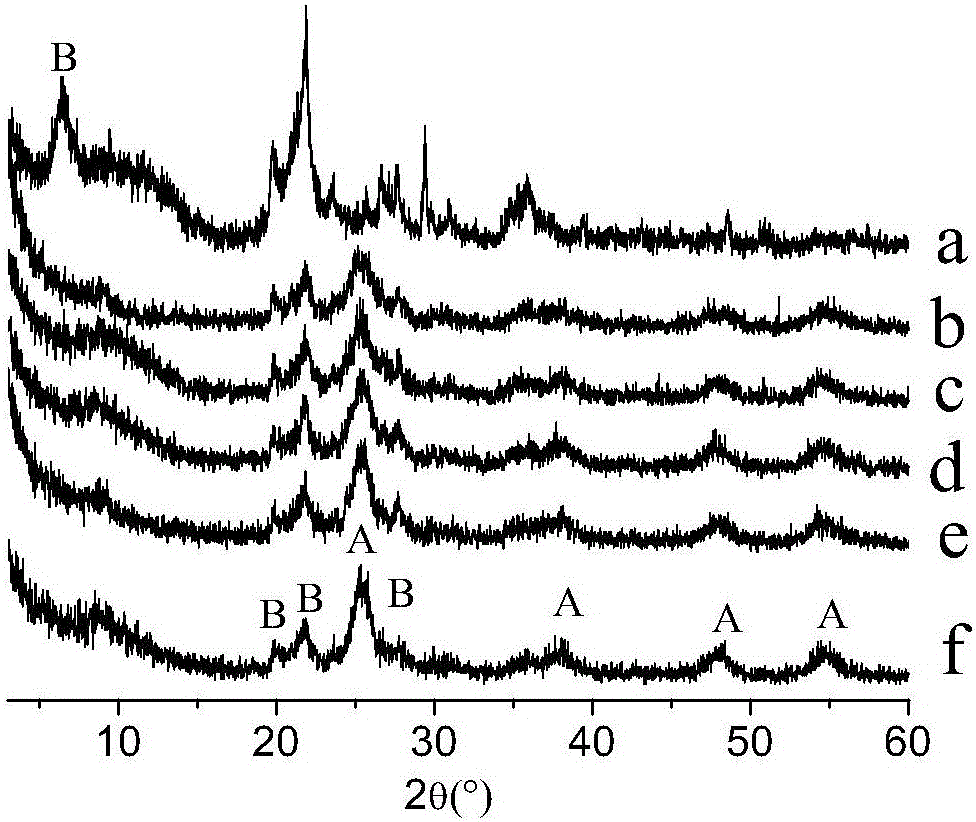

[0048]Experiments were carried out by changing different roasting temperatures. The roasting temperatures were 300°C, 400°C, 500°C and 600°C respectively, and four different samples were obtained, and then the prepared samples were used to carry out photocatalysis experiments on cyanide-containing wastewater, and the results were as follows: table 3. All the other are as embodiment 1. The original soil of bentonite and 4 bentonite composite materials obtained in embodiment 2 are carried out to XRD detection respectively, as image 3 shown.

[0049] Table 3 Example 2 Catalytic adsorption effect table

[0050] Calcination temperature / ℃

Embodiment 3

[0052] Experiments were carried out by changing different roasting times. The roasting time was 30min, 60min, 90min, 120min, 150min and 180min respectively, and different samples were obtained, and then the prepared samples were used to carry out photocatalytic experiments on cyanide-containing wastewater, and the results are shown in Table 4. . All the other are as embodiment 1.

[0053] Table 4 Example 3 Catalytic adsorption effect table

[0054] Roasting time / min

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com