Oral glucose liquid composition

A liquid composition and a technology for the composition, which are applied in the field of medical food, can solve problems such as affecting blood sugar, and achieve the effects of relieving thirst, reducing insulin resistance and having a simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

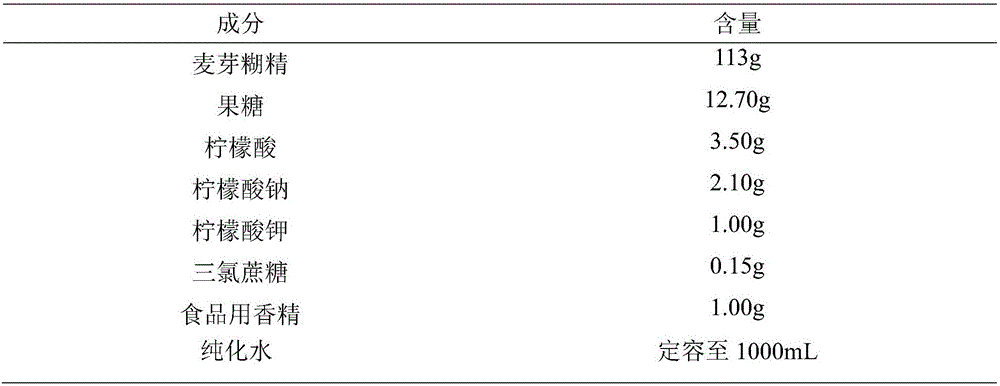

Embodiment 1

[0023]

[0024] Preparation Process:

[0025] 1) Weigh maltodextrin, fructose, citric acid, sodium citrate, potassium citrate, sucralose, and food flavors respectively according to the formula, and set aside;

[0026] 2) Add 20% of the total amount of water prepared in the No. 1 batching tank, and set aside;

[0027] 3) Add maltodextrin, fructose, citric acid, sodium citrate, potassium citrate, sucralose, and food flavorings into water in sequence, stir until completely dissolved, and adjust the pH to 3.5-4.5;

[0028] 4) Filter the above solution into the No. 2 batching tank, rinse the pipeline with an appropriate amount of water, and filter the flushing solution to the No. 2 batching tank;

[0029] 5) Set the volume in the No. 2 batching tank to the total volume of preparation;

[0030] 6) circulate and stir for 20 minutes;

[0031] 8) Filling at 85°C, 200mL / bottle;

[0032] 9) Sterilize at 90°C for 30 minutes to obtain a finished product.

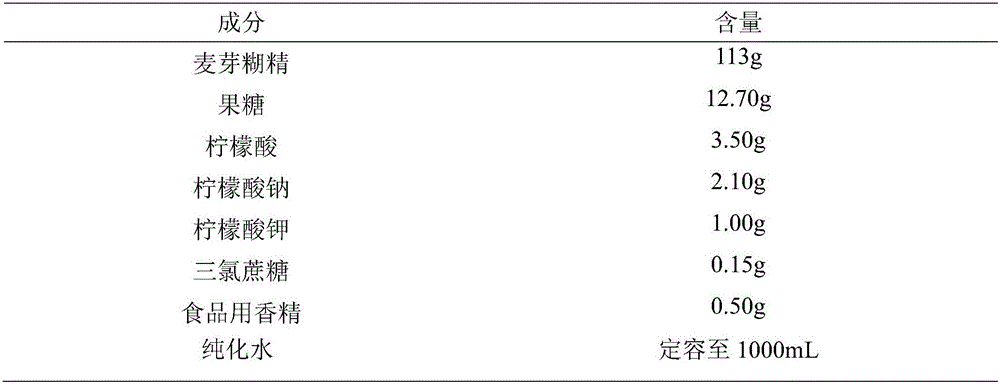

Embodiment 2

[0034]

[0035] Preparation Process:

[0036] 1) Weigh maltodextrin, fructose, citric acid, sodium citrate, potassium citrate, sucralose, and food flavors respectively according to the formula, and set aside;

[0037] 2) Add 20% of the total amount of water prepared in the No. 1 batching tank, and set aside;

[0038] 3) Add maltodextrin, fructose, citric acid, sodium citrate, potassium citrate, sucralose, and food flavorings into water in sequence, stir until completely dissolved, and adjust the pH to 3.5-4.5;

[0039] 4) Filter the above solution into the No. 2 batching tank, rinse the pipeline with an appropriate amount of water, and filter the flushing solution to the No. 2 batching tank;

[0040] 5) Set the volume in the No. 2 batching tank to the total volume of preparation;

[0041] 6) circulate and stir for 20 minutes;

[0042] 8) Filling at 85°C, 200mL / bottle;

[0043] 9) Sterilize at 115°C for 15 minutes to obtain a finished product.

Embodiment 3

[0045]

[0046] Preparation Process:

[0047] 1) Weigh maltodextrin, fructose, citric acid, sodium citrate, potassium citrate, sucralose, and food flavors respectively according to the formula, and set aside;

[0048] 2) Add 20% of the total amount of water prepared in the No. 1 batching tank, and set aside;

[0049] 3) Add maltodextrin, fructose, citric acid, sodium citrate, potassium citrate, sucralose, and food flavorings into water in sequence, stir until completely dissolved, and adjust the pH to 3.5-4.5;

[0050] 4) Filter the above solution into the No. 2 batching tank, rinse the pipeline with an appropriate amount of water, and filter the flushing solution to the No. 2 batching tank;

[0051] 5) Set the volume in the No. 2 batching tank to the total volume of preparation;

[0052] 6) circulate and stir for 20 minutes;

[0053] 8) Filling at 85°C, 200mL / bottle;

[0054] 9) Sterilize at 115°C for 30 minutes to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com