A simulated assembly method for continuous assembly construction of steel pipe arch rib segmental frame method

A steel tube arch rib and tire frame technology is applied in the field of simulation assembly for continuous assembly and construction of steel tube arch rib segment frame method, and can solve the problems of increasing the safety factor, complex control differential equations, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

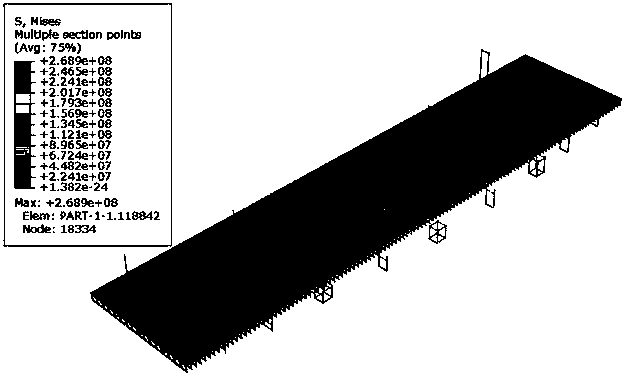

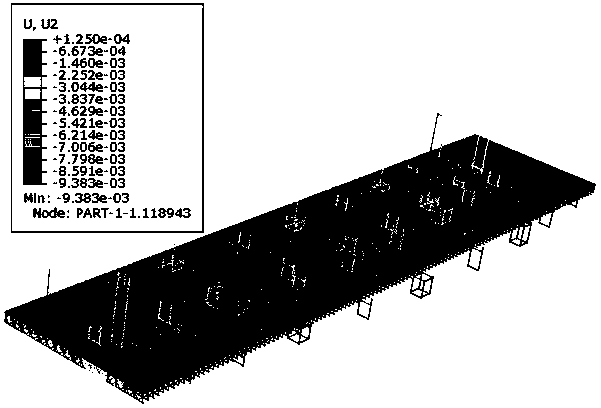

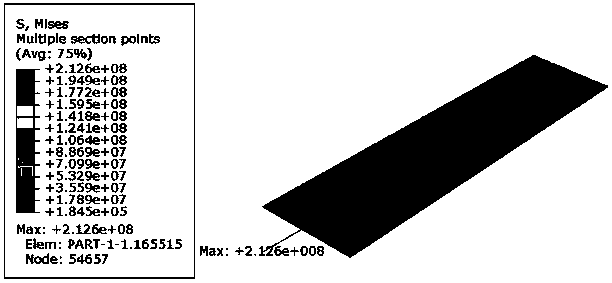

[0070] Such as figure 1 A simulated assembly method for the continuous assembly construction of a steel pipe arch rib segment tire frame method shown, including the following steps:

[0071]Step 1. Establishment of the finite element model of the assembly platform and the assembled tire frame: through data processing equipment and finite element analysis software, the spatial structure simulation model of the assembled platform of the steel pipe arch rib segment 1 to be assembled and the assembled tire frame is established;

[0072] The assembled platform is a pre-built horizontal support platform for the assembled tire frame to be installed, and the assembled tire frame is arranged on the assembled platform;

[0073] The assembled tire frame includes two sets of supporting tire frames for the assembly of the steel pipe arch rib segment 1 to be assembled, and each group of supporting tire frames includes a plurality of steel pipe arch rib segments 1 along the length direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com