Method for measuring calcium oxide and magnesium oxide content of tundish covering agent

A measurement method and covering agent technology, applied in chemical method analysis, measuring device, chemical analysis by titration method, etc., can solve the problems of long time consumption and high cost, and achieve the effect of simple equipment, reduced loss and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

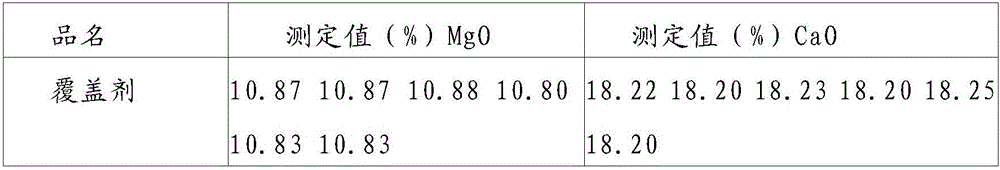

Examples

Embodiment Construction

[0026] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

[0027] 1. Method summary:

[0028] Use hydrochloric acid (65%), nitric acid (67%)-hydrofluoric acid (40%) to dissolve the sample in a polyethylene plastic beaker, add perchloric acid to smoke, (perchloric acid smoke must be exhausted, otherwise, it will affect For the determination of calcium and magnesium, there is black residue in the sample in the beaker. After the residue treatment, the calcium in the residue is zero. Therefore, it can be said that after a series of acid treatments in the early stage, the calcium and magnesium in the sample have been completely dissolved, so the later stage Calcium can be directly measured, and magnesium does not need to be treated with residue.) Remove it, after cooling, carefully add 5mL hydrochloric acid (65%) along the wall of the cup, and heat to dissolve the salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com