High-diffraction-intensity two-dimensional colloidal crystal-gold array/intelligent hydrogel composite material and visual sensor

A two-dimensional colloid and diffraction intensity technology, applied in the field of nanomaterials, can solve the problems of low visible light diffraction intensity, low reflectivity of colloidal microspheres, sensor limitations, etc., and achieve the effect of high diffraction intensity and good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

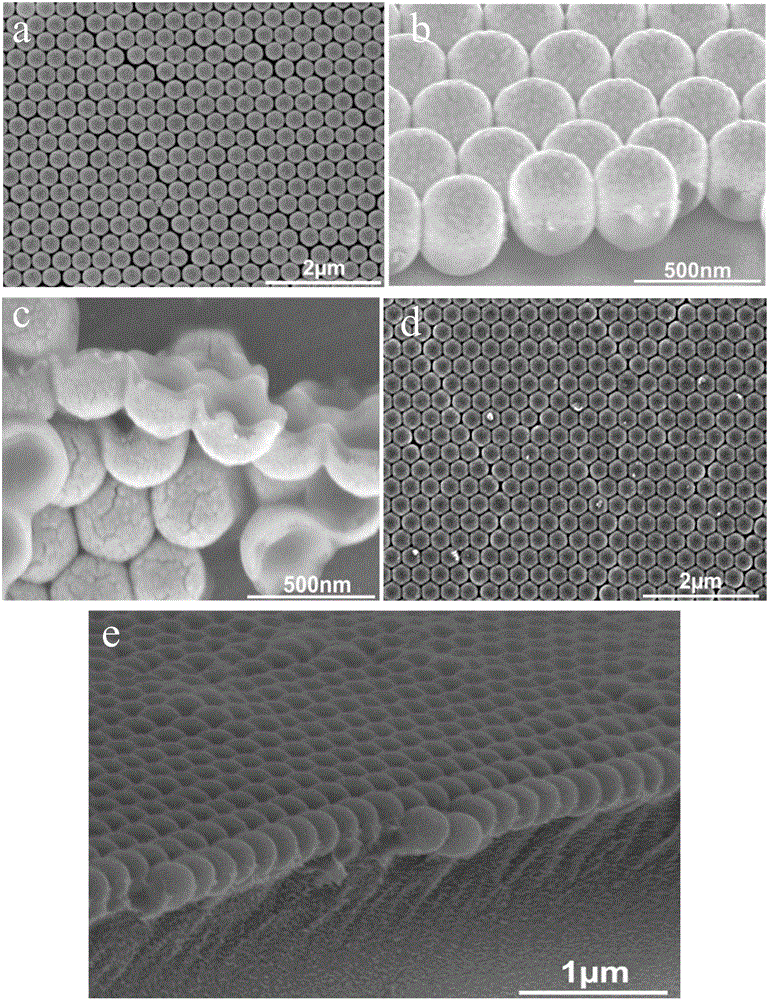

[0045] Such as Figure 5 As shown, a two-dimensional PS-Au array / smart hydrogel composite was prepared by the following steps:

[0046] Step a, put the glass slide into acetone, ethanol, and deionized water in turn for ultrasonic cleaning, each liquid is ultrasonically cleaned for 40 minutes, and then the cleaned glass slide is put into an oven for drying treatment, and the drying temperature is 70°C, drying time is 30 minutes; after the water on the slide is completely evaporated, place the slide in an ultraviolet ozone cleaner for 30 minutes of irradiation, so as to obtain a slide with good hydrophilicity on the surface.

[0047] Step b, take 40 microliters of polystyrene colloidal suspension (2.5wt.%) with a diameter of 350nm, and mix it with ethanol in equal volume, and then carry out ultrasonic oscillation treatment for 10min, so as to obtain polystyrene colloid with uniform composition Spherical ethanol dilution; put the glass slide treated in step a into the polystyren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com