A method for preparing niobium oxide target material by hot isostatic pressing

A technology of hot isostatic pressing and niobium oxide, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of long production cycle and high production cost of powder treatment, and increase material utilization and production. Efficiency, shrinkage reduction, production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

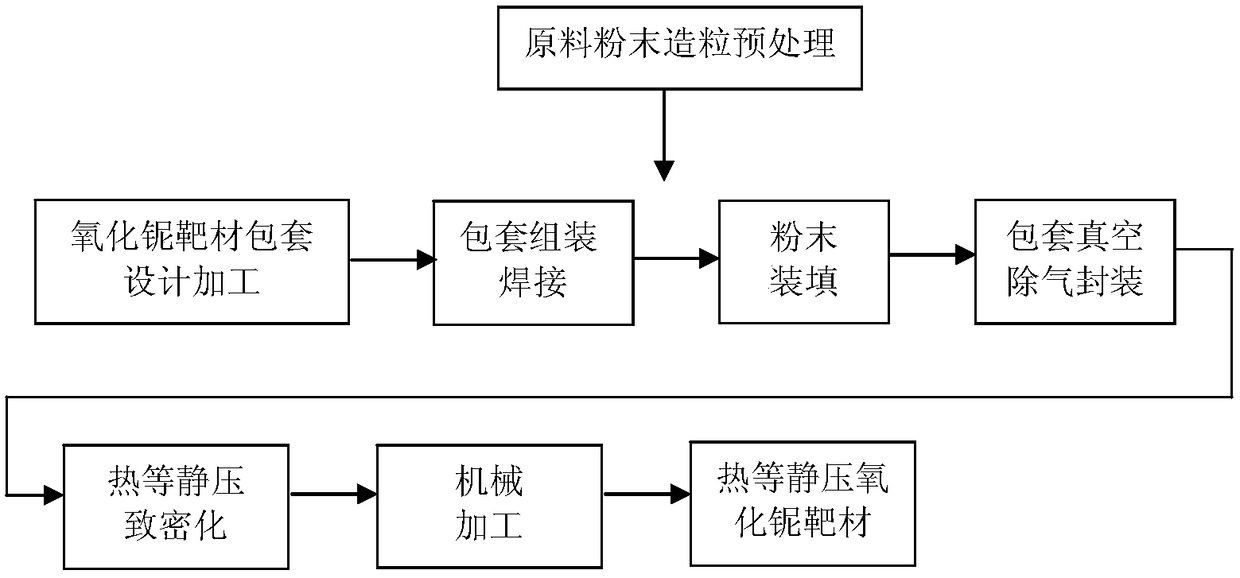

Method used

Image

Examples

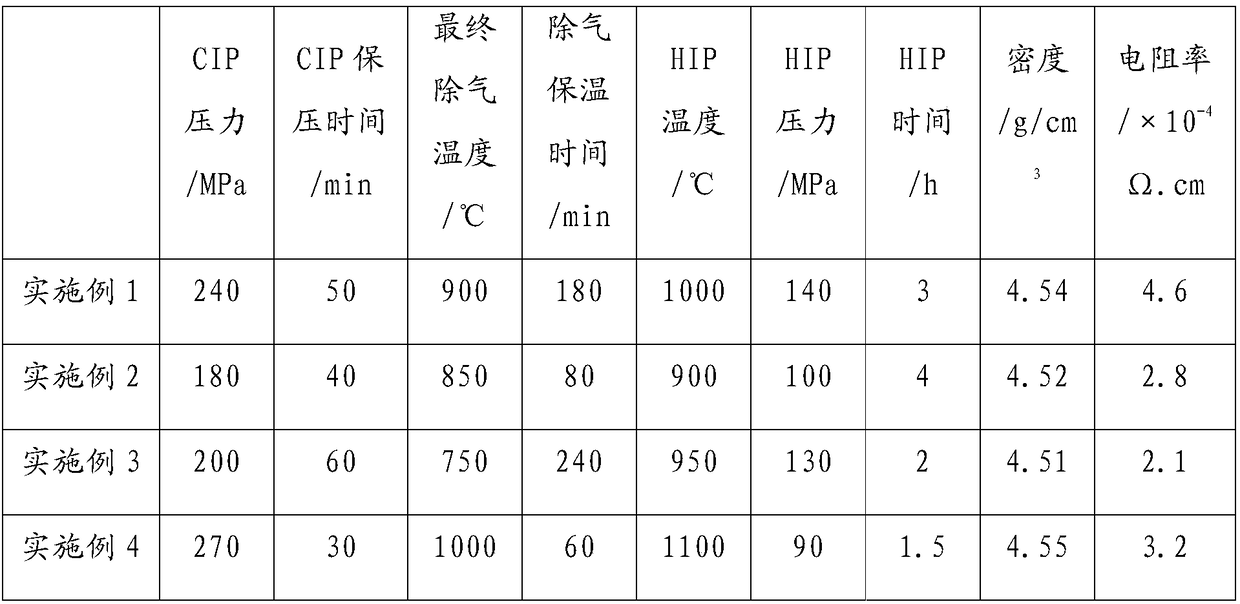

Embodiment 1

[0035] The niobium pentoxide powder with a purity of 99.99% was weighed and subjected to cold isostatic pressing and crushing. The cold isostatic pressing pressure was 240 MPa, and the holding time was 50 minutes. Put the obtained niobium pentoxide powder into the sheath, the relative tap density is 52%, and carry out vacuum thermal degassing after welding. The vacuum thermal degassing process is the final degassing temperature of 900 ° C, and the final vacuum degree is greater than 1×10 -3 Pa, keep warm for 180min on this basis. The oxygen loss was 4 wt% of the total oxygen content in the powder. The jacket after vacuum heat degassing is subjected to hot isostatic pressing densification treatment. The process parameters of hot isostatic pressing are: temperature 1000°C, pressure 140MPa, holding time 3h. After testing, the density of the niobium oxide target is 4.54g / cm 3 , the resistivity is 4.6×10 -4 Ω.cm.

Embodiment 2

[0037] The niobium pentoxide powder with a purity of 99.99% was weighed and subjected to cold isostatic pressing and crushing. The cold isostatic pressing pressure was 180 MPa, and the holding time was 40 minutes. The obtained niobium pentoxide powder is loaded into the sheath, the relative density of vibration is 54%, and vacuum heat degassing is carried out after welding. The vacuum thermal degassing process is the final degassing temperature of 850°C, and the final vacuum degree is greater than 1×10 -3 Pa, keep warm for 80min on this basis. The oxygen loss was 4.6 wt% of the total oxygen content in the powder. The jacket after vacuum heat degassing is subjected to hot isostatic pressing densification treatment. The process parameters of hot isostatic pressing are: temperature 900°C, pressure 100MPa, holding time 4h. After testing, the density of the niobium oxide target is 4.52g / cm 3 , the resistivity is 2.8×10 -4 Ω.cm.

Embodiment 3

[0039] The niobium pentoxide powder with a purity of 99.99% was weighed and subjected to cold isostatic pressing and crushing. The cold isostatic pressing pressure was 200 MPa, and the holding time was 60 minutes. The obtained niobium pentoxide powder is loaded into the sheath, the relative density of vibration is 51%, and vacuum heat degassing is carried out after welding. The vacuum thermal degassing process is the final degassing temperature of 750 °C, and the final vacuum degree is greater than 1×10 -3 Pa, keep warm for 240min on this basis. The oxygen loss is about 3.7wt% of the total oxygen content in the powder. The jacket after vacuum heat degassing is subjected to hot isostatic pressing densification treatment. The process parameters of hot isostatic pressing are: temperature 950°C, pressure 130MPa, holding time 2h. After testing, the density of the niobium oxide target is 4.51g / cm 3 , the resistivity is 2.1×10 -4 Ω.cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com