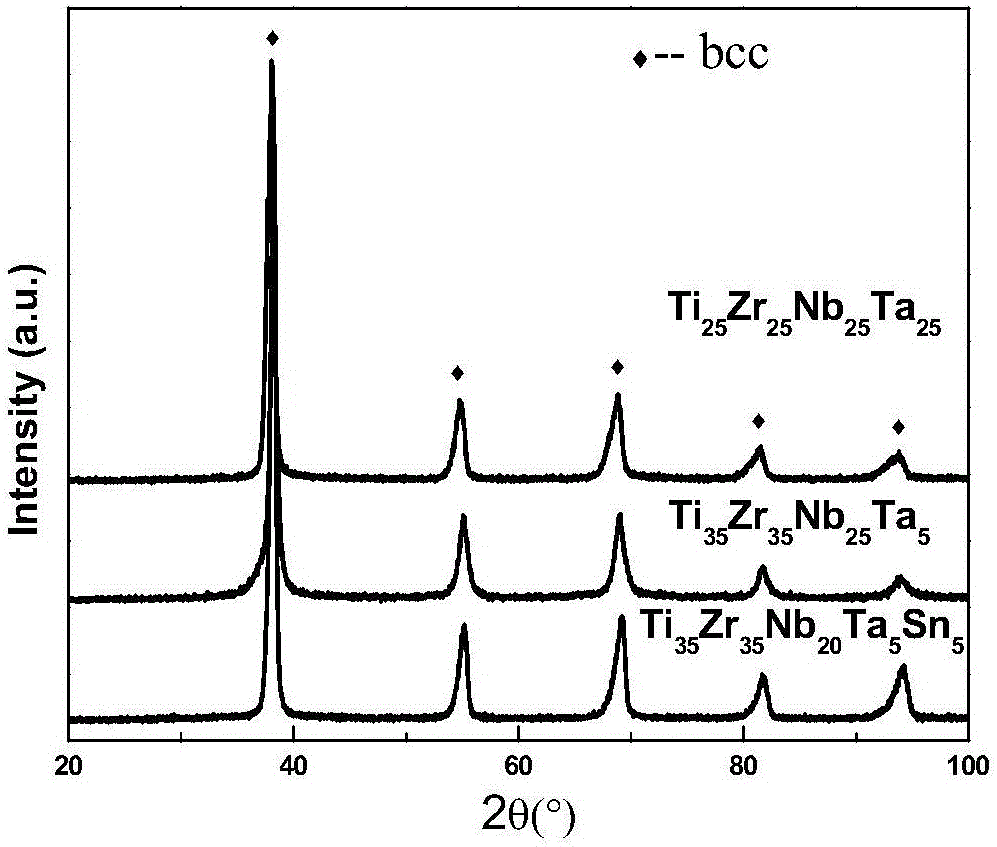

Biomedical TiZrNbTa high-entropy alloy and preparation method thereof

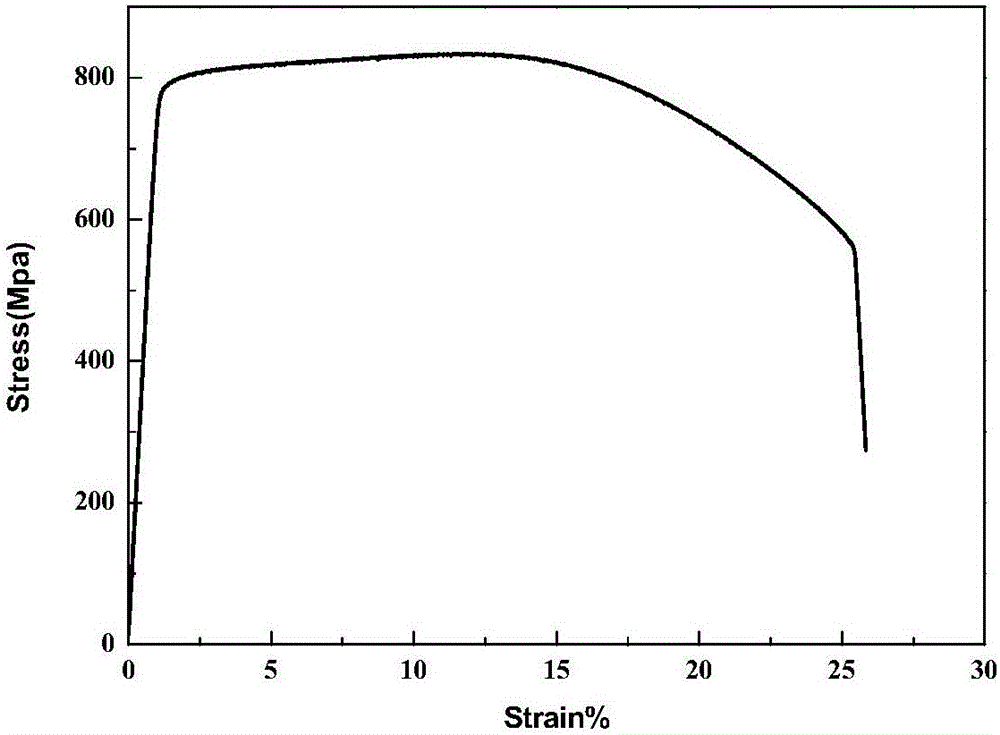

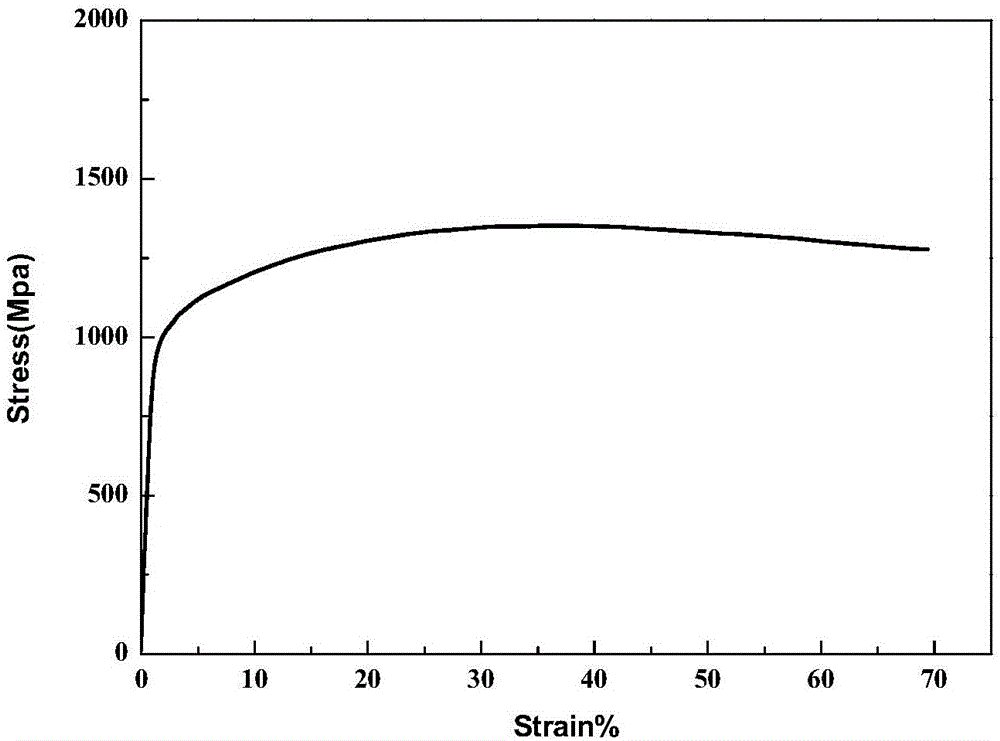

A high-entropy alloy and biomedical technology, which is applied in the field of high-strength and low-modulus xyMz-based biomedical high-entropy alloy and its preparation, can solve the problems of low wear resistance and corrosion resistance, low price, low elastic modulus and the like, Achieve the effects of good biocompatibility, ultra-high mechanical strength, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment: the preparation process of high entropy alloy is as follows:

[0030] (1) Raw material preparation: use metallurgical raw materials Ti, Zr, Nb, Ta, M and other metals with a purity of more than 99.9%, use sandpaper and a grinder to remove the oxide skin of the raw material metal, and use a balance to accurately weigh it for smelting alloys. The alloy composition is shown in Table 1.

[0031] Table 1 is the nominal composition (at%) of three kinds of embodiment alloys

[0032]

[0033]

[0034] (2) Melting and suction casting of high-entropy alloys: the present invention adopts vacuum non-consumable arc melting of alloys. Take the raw materials and put them into the vacuum electric arc furnace respectively, put the elements with high melting point on the upper layer, and cover the lower melting point elements. During smelting, it is required to put the elements with high melting point on the upper layer; Adjust the current to melt the high melting point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com