Near ultraviolet excited charge compensation type red-light phosphate light emitting material and preparation method thereof

A technology of charge compensation and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of wide application limitations, harsh synthesis conditions, and insufficient efficiency, and achieve high ultraviolet light absorption rate, low synthesis temperature, and full reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

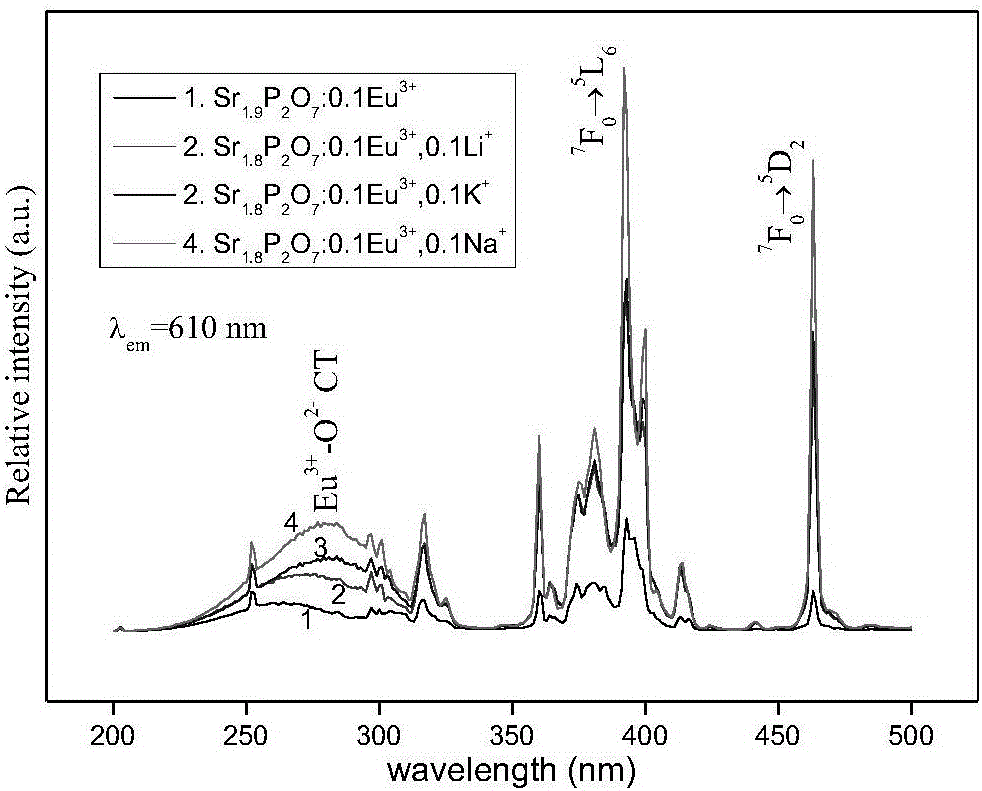

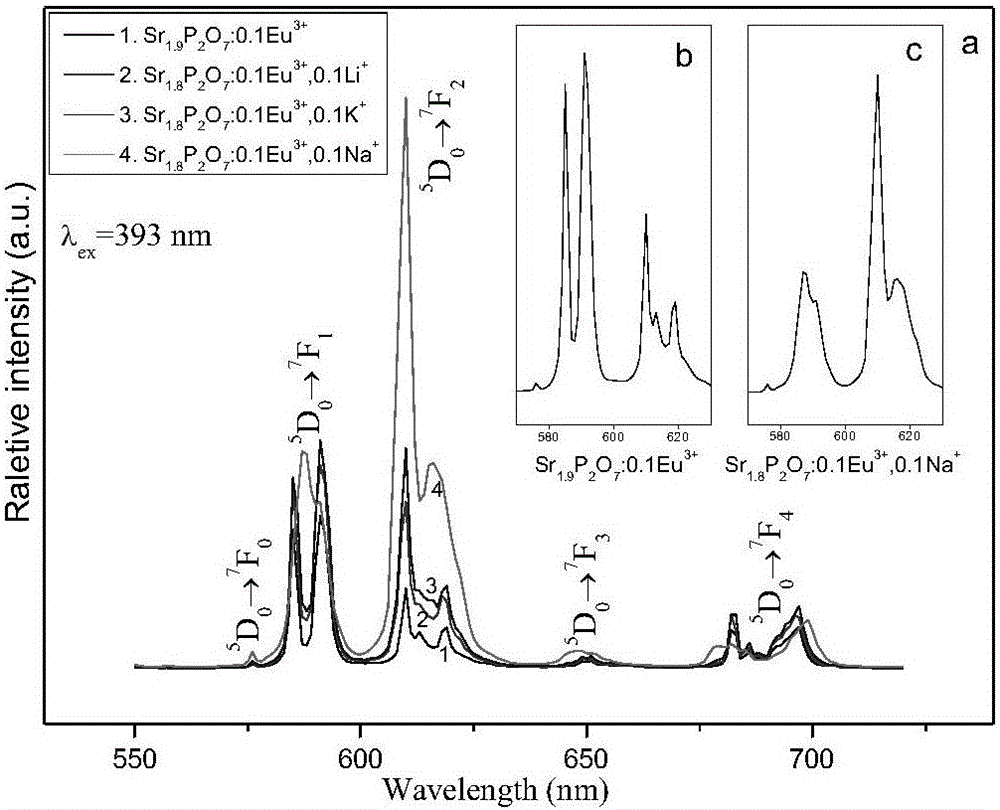

Embodiment 1

[0028] 1) Accurately weigh SrCO 3 1.3287g, (NH 4 ) 2 HPO 4 1.3206g, Li 2 CO 3 0.0185g, Eu 2 o 3 0.088g, and placed in an agate mortar, ground for 1h to make it evenly mixed to obtain a mixed solid powder;

[0029] 2) Using the high-temperature solid-phase method, place the above-mentioned mixed solid powder in a corundum crucible, raise the temperature from room temperature to 1050°C at a rate of 25°C / min in an air atmosphere, and calcinate at 1050°C for 2 hours. After the calcination, The system is naturally cooled to room temperature with the furnace temperature, and the product is further ground to obtain the chemical composition of Sr 1.8 P 2 o 7 :0.1Eu 3+ ,0.1Li + red light phosphate phosphor.

Embodiment 2

[0031] 1) Accurately weigh SrCO 3 1.3287g, (NH 4 ) 2 HPO 4 1.3206g, K 2 CO 3 0.0346g, Eu 2 o 3 0.088g, and placed in an agate mortar, ground for 1h to make it evenly mixed to obtain a mixed solid powder;

[0032] 2) Using the high-temperature solid-phase method, place the above-mentioned mixed solid powder in a corundum crucible, raise the temperature from room temperature to 1050°C at a rate of 25°C / min in an air atmosphere, and calcinate at 1050°C for 2 hours. After the calcination, The system is naturally cooled to room temperature with the furnace temperature, and the product is further ground to obtain the chemical composition of Sr 1.8 P 2 o 7 :0.1Eu 3+ ,0.1K + red light phosphate phosphor.

Embodiment 3

[0034] 1) Accurately weigh SrCO 3 1.4468g, (NH 4 ) 2 HPO 4 1.3206g, Na 2 CO 3 0.0053g, Eu 2 o 3 0.018g, and placed in an agate mortar, ground for 1h to make it evenly mixed to obtain a mixed solid powder;

[0035] 2) Using the high-temperature solid-phase method, place the above-mentioned mixed solid powder in a corundum crucible, raise the temperature from room temperature to 1050°C at a rate of 25°C / min in an air atmosphere, and calcinate at 1050°C for 2 hours. After the calcination, The system is naturally cooled to room temperature with the furnace temperature, and the product is further ground to obtain the chemical composition of Sr 1.96 P 2 o 7 :0.02Eu 3+ ,0.02Na + red light phosphate phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com