Synthetic method of polyhydroxy alcohol fatty acid ester by scratch film evaporator

A technology of wiped film evaporator and synthesis method, which is applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc. It can solve the problems of water not easy to escape, poor heat transfer effect, etc., and achieve continuous and uninterrupted production , high-efficiency production, and stable film flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

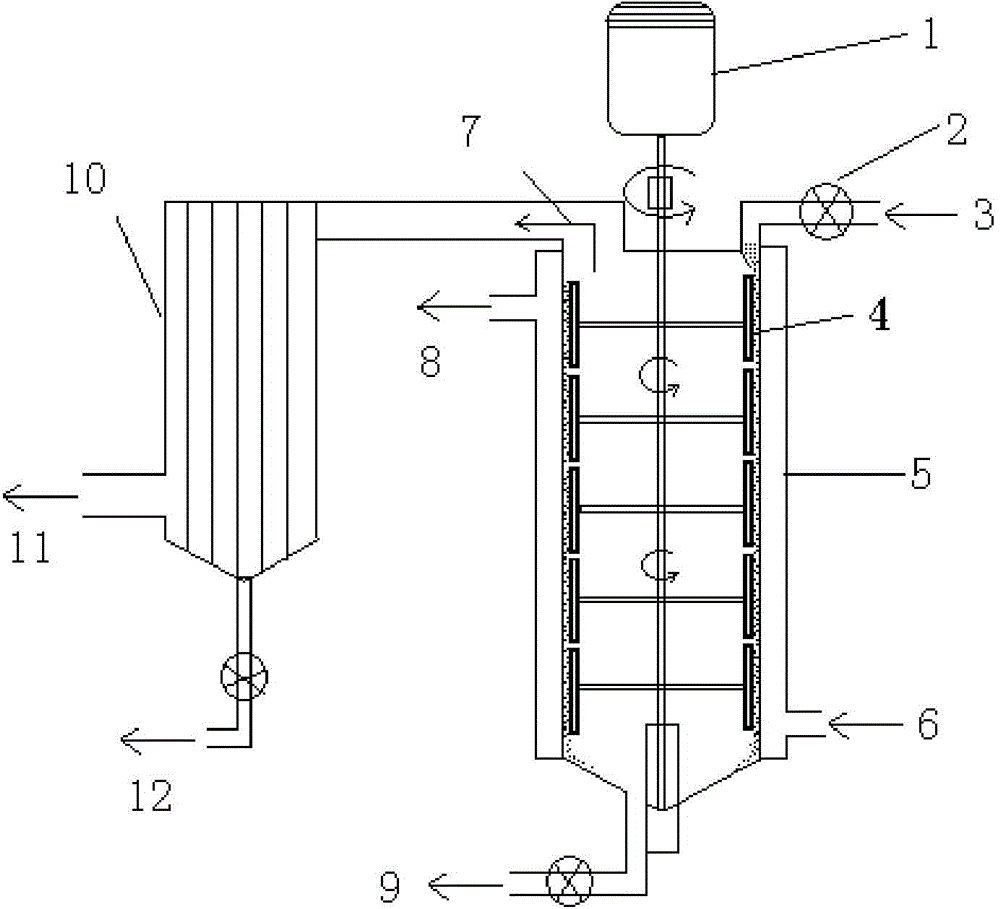

Image

Examples

Embodiment 1

[0048] Mix trimethylolpropane and n-hexanoic acid according to the molar ratio of hydroxyl and carboxyl groups of 1:1, heat and stir to make them dissolve in each other. Firstly, the heat transfer oil circulation is started, and the heat transfer oil is input from the heat transfer oil inlet and output from the heat transfer oil outlet, so that the wiped film evaporator reaches 180°C. Secondly, turn on the vacuuming equipment, and perform vacuuming operation on the equipment system through the vacuum pumping port, so that the internal pressure of the wiped film evaporator reaches 60KPa. Then turn on the external condenser and let it reach 10°C. After the above three items are stabilized at the set parameters, turn on the feeding pump, so that the reactant mixture flows into the wiper film evaporator through the material mixture inlet, and at the same time turn on the motor. Driven by the motor, the wiper device rotates and flows into the scraper The material mixture in the fi...

Embodiment 2

[0050] Mix pentaerythritol and n-heptanoic acid according to the molar ratio of hydroxyl and carboxyl groups of 1:1.06, heat and stir to make them dissolve. First turn on the heat conduction oil circulation to make the wiped film evaporator reach 180°C. Next, turn on the vacuuming equipment, and perform vacuuming operation on the equipment system through the vacuum pumping port, so that the internal pressure of the wiped film evaporator reaches the set 55KPa, and then turn on the external condenser to make it reach 20°C. After the above three items are stable and the parameters are set, turn on the feeding pump, so that the reactant mixture flows into the wiper film evaporator through the material mixture inlet, and at the same time turn on the motor, driven by the motor, the wiper rotates and makes the flow into the scraper The material mixture in the film evaporator forms a uniform liquid film on the inner wall. The liquid film is rapidly heated to undergo an esterification...

Embodiment 3

[0052] Mix trimethylolpropane and n-octanoic acid according to the molar ratio of hydroxyl and carboxyl groups of 1:1.15, heat and stir to make them dissolve. First turn on the heat transfer oil circulation to make the wiped film evaporator reach 190°C. Secondly, turn on the vacuuming equipment, and perform vacuuming operation on the equipment system through the vacuum pumping port, so that the internal pressure of the wiped film evaporator reaches 50KPa. Then turn on the external condenser and let it reach 5°C. After the above three items are stabilized at the set parameters, turn on the feeding pump, so that the reactant mixture flows into the wiper film evaporator through the material mixture inlet, and at the same time turn on the motor. Driven by the motor, the wiper device rotates and flows into the scraper The material mixture in the film evaporator forms a uniform liquid film on the inner wall. The liquid film is rapidly heated to undergo an esterification reaction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com