Additive and method for improving performance of permanent magnetic ferrite

A permanent magnet ferrite and additive technology, which is applied in the field of additives to improve the magnetic properties of permanent magnet ferrite, can solve the problems of increasing material cost pressure, high price of cobalt oxide, and influence on pass rate, etc., and achieves low cost, excellent magnetic properties, The effect of improving the magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

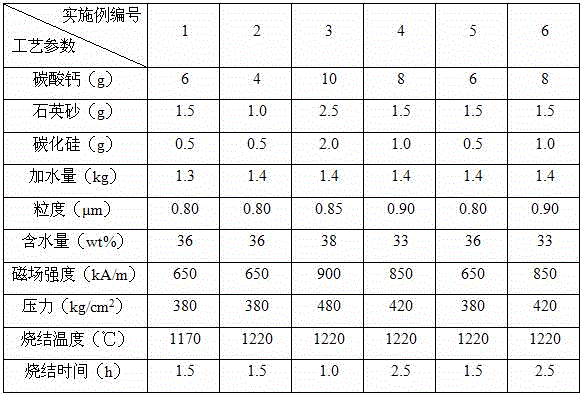

[0027] The additives for improving the magnetic performance of permanent magnet ferrite in Examples 1-6 are composed of calcium carbonate, quartz sand and silicon carbide. The specific mass ratio is shown in the 2nd to 4th rows of Table 1, and they are respectively numbered 1# to 6# , wherein, the silicon carbide in 1#, 2#, and 5# additives was stirred and cleaned for 4 hours in an ammonia solution with a pH value of 10, and the silicon carbide in 3# and 4# additives was cleaned in a sodium hydroxide solution with a pH value of 14 Stir and wash for 6 hours, and the silicon carbide in the 6# additive is not washed with alkaline solution.

[0028] The method for improving the magnetic properties of permanent ferrite by applying the 1#~6# additives comprises the following steps:

[0029] (1) Add 6 parts (1 kg each) of permanent magnet ferrite calcined materials to the ball mill respectively, then add the 1#~6# additives respectively, and then add water to the ball mill (see Table...

Embodiment 4

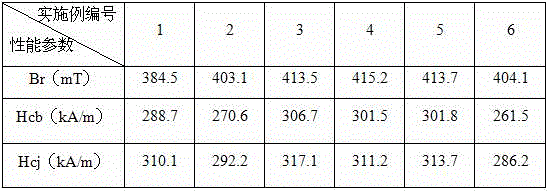

[0042] Example 4 obtained the best magnetic properties, with Br as high as 415.2mT, Hcb as high as 301.5kA / m, and Hcj as high as 311.2kA / m. It shows that the treatment of silicon carbide with alkaline solution can increase the surface area of silicon carbide, improve the reactivity of silicon carbide, make it easier to react with calcium carbonate to form silicate substances, improve the microstructure of the magnet, and coordinate the amount of water added, Reasonable selection of parameters such as ball mill particle size, magnetic field strength, and sintering temperature further greatly improves the magnetic properties of permanent ferrite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com