Hot-process phosphoric acid production device with low-temperature heat energy recovery

A technology of heat energy recovery and thermal phosphoric acid, which is applied in the field of chemical engineering, can solve problems such as heat pollution, heat waste, and water consumption, and achieve the effects of reducing environmental pollution, reducing product losses, and achieving good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

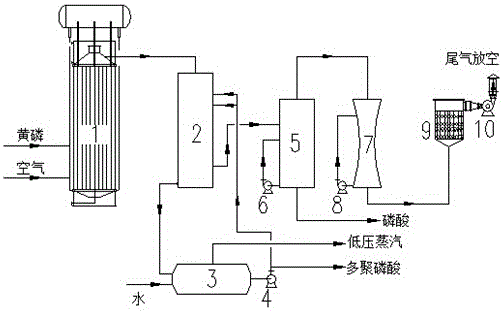

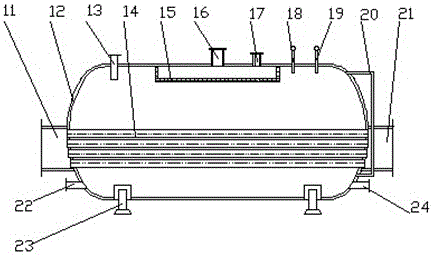

[0020] Embodiment 1: as figure 1 , 2 As shown, the thermal phosphoric acid production device with low-temperature heat energy recovery includes a combustion tower 1, a primary absorption tower 2, a shell and tube boiler 3, a secondary absorption tower 5, a venturi 7, a wire mesh eliminator 9, and an induced draft fan 10 The combustion tower 1 communicates with the secondary absorption tower 5 through the first-level absorption tower 2, and the secondary absorption tower 5 communicates with the wire mesh demister 9 through the Venturi 7, and the wire mesh demister 9 is connected with the induced draft fan 10, and the shell Type boiler 3 is connected with primary absorption tower 2 through primary phosphoric acid pump 4 and forms a closed loop; shell-and-tube boiler 3 includes polyphosphoric acid inlet 11, furnace body 12, heat exchange tube 14, liquid-gas separator 15, main Steam valve 16, auxiliary steam valve 17, water level gauge 20, polyphosphoric acid outlet 21, water inl...

Embodiment 2

[0022] Embodiment 2: The structure of this thermal phosphoric acid production device with low-temperature heat energy recovery is the same as that of Embodiment 1, except that the primary absorption tower 2 is an empty tower with nozzles, and the nozzles in the tower have 4 layers; the heat exchange tubes 14 are thin-walled tubes with uniform Arranged, the pipe diameter is 20mm, the wall thickness is 2.5mm, the uppermost layer of the heat exchange tube is required to be 120mm below the horizontal centerline of the furnace body, and the water level in the boiler is 30mm below the horizontal centerline of the furnace body.

[0023]During use, yellow phosphorus and natural air are burned in thermal phosphoric acid combustion tower 1, and the phosphorus pentoxide gas that combustion forms enters primary absorption tower 2, and mass percent concentration 115% (as H 3 PO 4 The polyphosphoric acid is atomized through the nozzle, and the polyphosphoric acid is sprayed from top to bott...

Embodiment 3

[0024] Embodiment 3: The structure of this thermal phosphoric acid production device with low-temperature heat energy recovery is the same as that of Embodiment 1, except that the first-stage absorption tower 2 is a dynamic wave absorption tower with nozzles, and the nozzles in the tower are arranged in two layers, one for each layer; The heat pipes 14 are uniformly arranged thin-walled tubes with a diameter of 50mm and a wall thickness of 4.5mm. The uppermost layer of heat exchange tubes is required to be 150mm below the horizontal centerline of the furnace body, and the water level in the boiler is 10mm below the horizontal centerline of the furnace body.

[0025] During use, yellow phosphorus and natural air are burned in the thermal phosphoric acid combustion tower 1, and the phosphorus pentoxide formed by combustion enters the primary absorption tower 2, and the mass percentage concentration is 118% (in the form of H 3 PO 4 The polyphosphoric acid is atomized through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com