Electrode and preparation method thereof, biosensor and enzyme biofuel cell

A biological enzyme and electrode technology, applied in the field of materials, can solve the problems that the output power density of enzyme biofuel cells cannot meet the actual needs, and achieve the effects of improving service life, expanding surface area, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

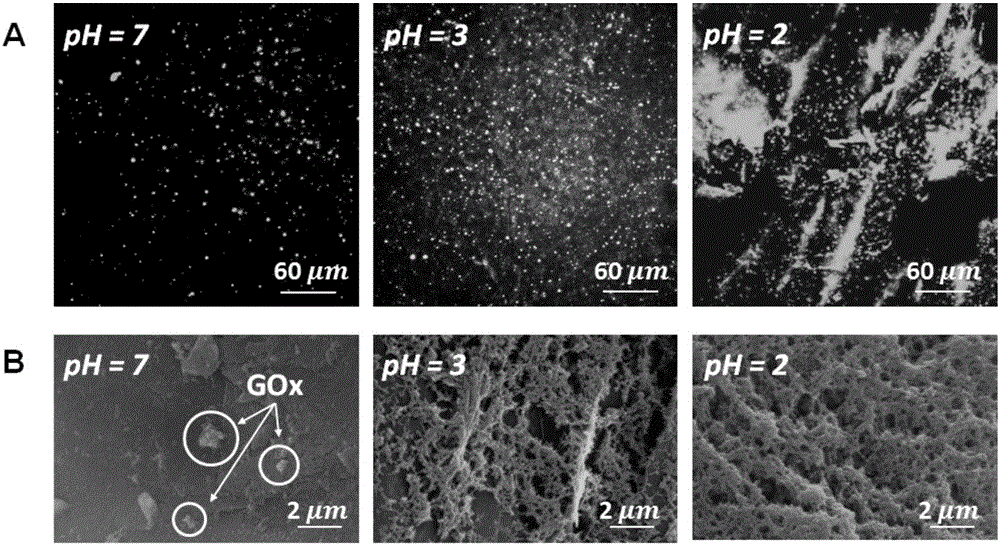

[0057] Embodiment 1: glucose oxidase / carbon paper electrode (GOx pH=x / CP) preparation

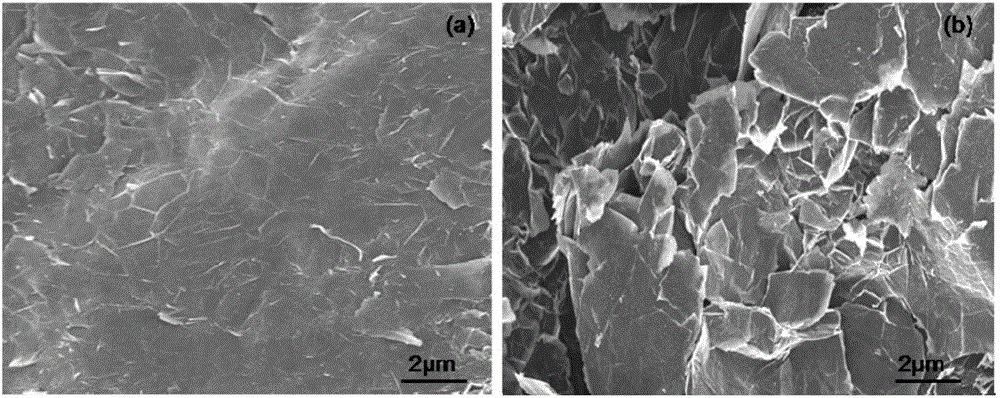

[0058] (1) Electrode surface treatment: drop the acid onto the surface of the carbon paper (CP) by drop coating to wet the surface of the carbon paper, and let it stand at room temperature for 5 minutes, then clean the surface of the carbon paper with a large amount of deionized water until neutral, Finally, let it dry at room temperature. The treated electrode surface as figure 2 shown.

[0059] (2) Utilize 0.2mol / L disodium hydrogen phosphate and 0.2mol / L sodium dihydrogen phosphate to prepare a phosphate (PBS) buffer solution with a concentration of 0.1mol / L and a pH of 7.2, and adjust the pH value with concentrated phosphoric acid 2, 3, 4, 5, 7 in PBS buffer.

[0060] (3) Incubate glucose oxidase (GOx) with PBS buffer solutions of different pH values, add glucose oxidase to PBS buffer solutions with different pH values, keep the temperature at 4°C, and the enzyme concentration in ...

Embodiment 2

[0063] Embodiment 2: glucose oxidase / carbon paper electrode (GOx pH=3 / CP) performance test

[0064] The electrode preparation method is the same as in Example 1, wherein, in step (2), the pH value of the buffer solution is 3.

[0065] The electrode performance test uses a standard three-electrode system: GOx pH=3 / CP is the working electrode, the platinum sheet is the counter electrode, and the Ag / AgCl electrode is the reference electrode. The cyclic voltammetry curve test is performed at room temperature using an electrochemical workstation CHI660E (Shanghai Chenhua, China), and high-purity argon gas is used to bubble before the test. 30 minutes. Test results such as Image 6 shown. in, Image 6 a is when the electrolyte is 0.1M PBS buffer with pH 7.2 containing 0.1M β-D-glucose, the working electrode is GOx pH=3 Cyclic voltammogram of / CP; Image 6 b is when the electrolyte is 0.1M PBS buffer solution with a pH of 7.2, and the working electrode is GOx pH=3 Cyclic vo...

Embodiment 3

[0066] Embodiment 3 direct electron transferase biofuel cell (anode is GOx pH=3 / CP) battery performance:

[0067] (1) Electrode GOx pH=3 The preparation method of / CP is the same as that of Example 2.

[0068] (2) Construction of enzyme biofuel cell: the schematic diagram of the cell structure is as follows Figure 7 shown. The battery consists of two compartments connected by a salt bridge consisting of agar and saturated potassium chloride solution.

[0069] (3) The electrolyte in the anode compartment is 0.1MPBS buffer solution containing 0.1Mβ-D-glucose, and high-purity argon gas is bubbled for 30 minutes before the battery works to remove the oxygen in the electrolyte.

[0070] (4) The cathode of the cathode chamber is 2cm 2 Platinum sheet, the electrolyte is B-R buffer solution, the pH is 3, the battery is bubbled with high-purity oxygen for 30 minutes before working, and the bubbles are continued to make the oxygen in the electrolyte saturated, and the working tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com