Curing and dry heaping method for fine grained tailings

A technology for fine-grained tailings and tailings, applied in climate change adaptation, embankment, coastline protection, etc., can solve problems such as dry tailings stacking, and achieve the effects of less construction work, shorter distances, and lower tailings transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further describe the present invention, a fine-grained tailing solidification dry stacking method of the present invention will be further described below in conjunction with the accompanying drawings and examples.

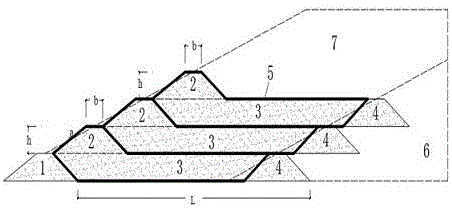

[0026] Depend on figure 1 The schematic diagram of storage of a kind of fine-grained tailings solidification dry stacking method of the present invention shows that a kind of fine-grained tailings solidification dry stacking method of the present invention determines the site according to the mine planning requirements, through the tailings dry stockpile site Site investigation to understand the engineering geology and hydrogeology of the tailings dry storage site; and then determine the tailings consolidation agent material through the proportion test according to the concentration, particle size distribution and mineral composition of the tailings discharged from the concentrator. According to the area occupied by the tailings dry stockpile an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com