Mixed flocculating agent capable of accelerating settling of superfine grain tailing flocculation and application thereof

A flocculant and ultra-fine particle technology, which is applied in the field of metallurgical beneficiation, can solve the problems of poor tailings dry stacking process, unfavorable comprehensive utilization of resources and environmental protection, and difficulty in flocculation and settlement of ultra-fine tailings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

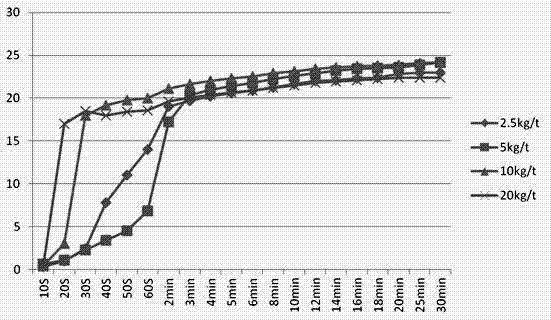

[0150]Take 600g of polyacrylamide with a molecular weight of 13 million to 14 million, add water to make 1200kg of polyacrylamide aqueous solution with a mass fraction of 0.05%, and then make a mixed flocculant with 20 to 40 mesh quartz sand at a mass ratio of 1.2:1 A total of 2200kg. When used, the amount of dry ore is added at 22kg / t. The quality of the dry ore = total mass of ore pulp × mass concentration of ore pulp, the same below.

Embodiment 2

[0152] Take 400g of polyacrylamide with a molecular weight of 13 million to 14 million, add water to make 200kg of polyacrylamide aqueous solution with a mass fraction of 0.2%, and then make a mixed flocculant with 20 to 40 mesh quartz sand at a mass ratio of 4:1 A total of 1000kg, when in use, add 10kg / t of dry ore.

Embodiment 3

[0154] Take 1000g of polyacrylamide with a molecular weight of 13 million to 14 million, add water to make 333kg of polyacrylamide aqueous solution with a mass fraction of 0.3%, and then make a mixed flocculant with 20 to 40 mesh quartz sand at a mass ratio of 0.3:1 A total of 1330kg, when used, according to 13kg / t dry ore dosage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com