Preparation method for forming calcium-containing nanosheet film layer on surface of sandblasted and acid-etched titanium

A nano-sheet and sandblasting technology is applied in the field of biomedical materials to achieve the effects of improving osseointegration ability, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

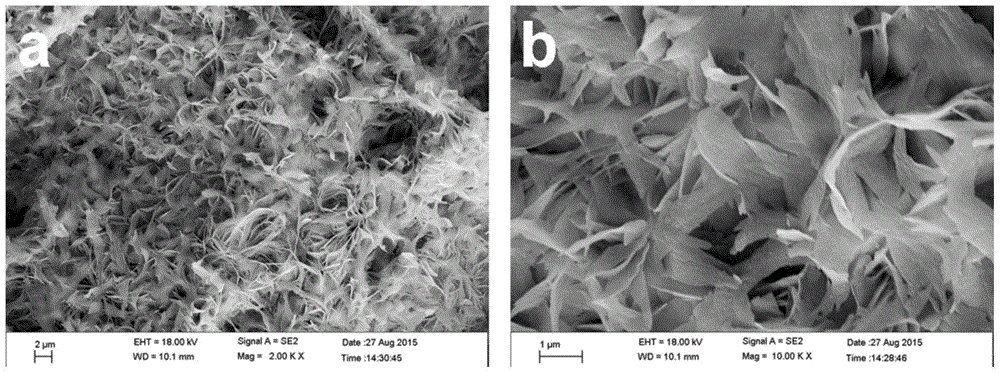

Embodiment 1

[0022] A preparation method for forming a calcium-containing nano-sheet film layer on the surface of titanium by sandblasting and acid etching, comprising the following steps:

[0023] Step A) Pretreatment of pure titanium: the use of labels is 600 in sequence # , 800 # , 1200 # , 1500 # The pure titanium sample was polished step by step with fine sandpaper from coarse to fine. Then use double-distilled water, absolute ethanol, and double-distilled water to ultrasonically clean for 5 minutes each, and dry for use.

[0024] Step B) Sand blasting treatment: use 80 mesh Al on the surface of the pure titanium sample in step A) 2 o 3 The sand is blasted at a distance of 1.5cm from the pure titanium surface for 15s under a pressure of 0.4MPa.

[0025] Step C) Acid etching treatment: Treat the pure titanium sample treated in step B) at room temperature in a mixture of nitric acid and hydrofluoric acid for 10 minutes. The mixed acid formula is double distilled water by volume: H...

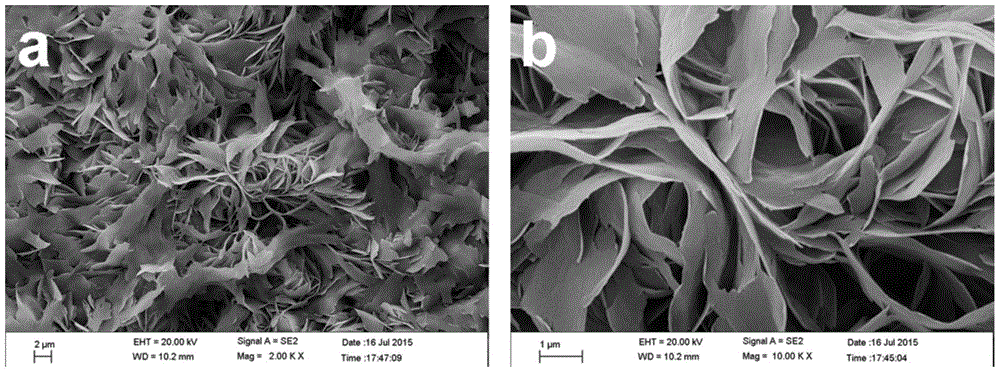

Embodiment 2

[0028] A preparation method for forming a calcium-containing nano-sheet film layer on the surface of titanium by sandblasting and acid etching, comprising the following steps:

[0029] Step A) Pretreatment of pure titanium: the use of labels is 600 in sequence # , 800 # , 1200 # , 1500 # The pure titanium sample was polished step by step with fine sandpaper from coarse to fine. Then use double-distilled water, absolute ethanol, and double-distilled water to ultrasonically clean for 5 minutes each, and dry for use.

[0030] Step B) Sand blasting treatment: use 80 mesh Al on the surface of the pure titanium sample in step A) 2 o 3 The sand is blasted at a distance of 1.5cm from the pure titanium surface for 15s under a pressure of 0.4MPa.

[0031] Step C) Acid etching treatment: Treat the pure titanium sample treated in step B) at room temperature in a mixture of nitric acid and hydrofluoric acid for 10 minutes. The mixed acid formula is double distilled water by volume: H...

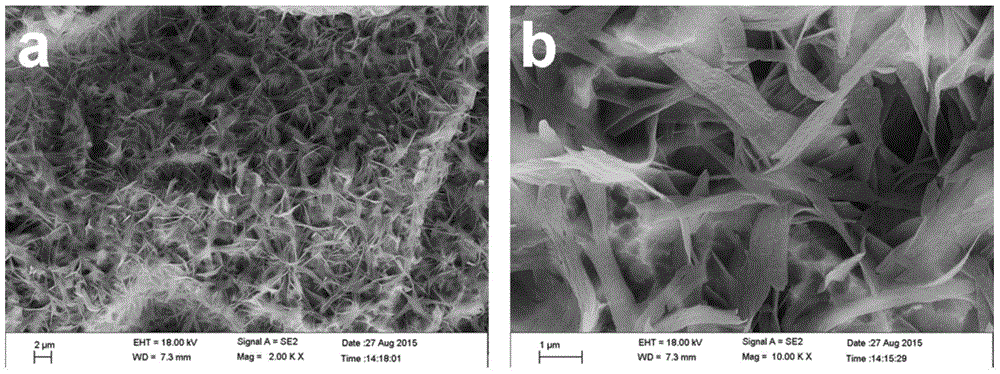

Embodiment 3

[0034] A preparation method for forming a calcium-containing nano-sheet film layer on the surface of titanium by sandblasting and acid etching, comprising the following steps:

[0035]Step A) Pretreatment of pure titanium: the use of labels is 600 in sequence # , 800 # , 1200 # , 1500 # The pure titanium sample was polished step by step with fine sandpaper from coarse to fine. Then use double-distilled water, absolute ethanol, and double-distilled water to ultrasonically clean for 5 minutes each, and dry for use.

[0036] Step B) Sand blasting treatment: use 80 mesh Al on the surface of the pure titanium sample in step A) 2 o 3 The sand is blasted at a distance of 1.5cm from the pure titanium surface for 15s under a pressure of 0.4MPa.

[0037] Step C) Acid etching treatment: Treat the pure titanium sample treated in step B) at room temperature in a mixture of nitric acid and hydrofluoric acid for 10 minutes. The mixed acid formula is double distilled water by volume: HF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com