A kind of yttrium-iron-based alloy material, preparation method and application

A technology of iron-based alloys and bulk materials, applied in the field of yttrium-iron-based alloy materials, can solve the problems of disproportionation and decomposition crystal structure, low reversible capacity, low hydrogen storage capacity, etc., and achieve small cycle hysteresis and high hydrogen storage capacity The effect of high and low hydrogen absorption temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

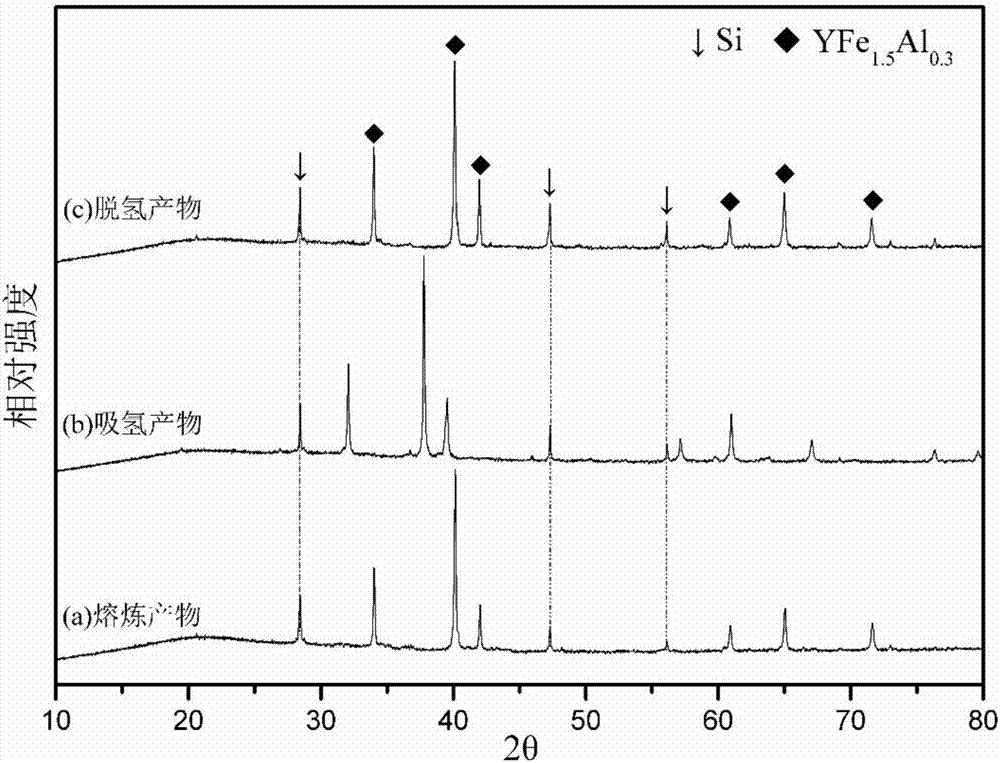

Embodiment 1

[0038] (1) Put yttrium block, iron block and aluminum block (purity not less than 99wt.%) according to molecular formula YFe 1.5 al 0.3 , that is, yttrium block, iron block and aluminum block are mixed evenly according to the mass fraction of 49.18%, 46.34% and 4.48%, and melted in an electric arc melting furnace at 1400 ° C for 5 minutes, and the alloy ingot is obtained after cooling; the vacuum chamber of the electric arc melting furnace The vacuum is 1.0x10 -3 Pa.

[0039] (2) Turn over the alloy ingot obtained in step (1), and re-melt and cool, so that the smelting is repeated 5 times. The re-melting is carried out in an electric arc melting furnace, and the vacuum degree in the vacuum chamber of the arc melting furnace is 1.0x10 -3 Pa, temperature and time are the same as step (1). The obtained ingot is placed in an argon protective atmosphere at a temperature of 22-25°C.

[0040] (3) Crushing the ingot into a powder state in an argon protective atmosphere to obtain ...

Embodiment 2

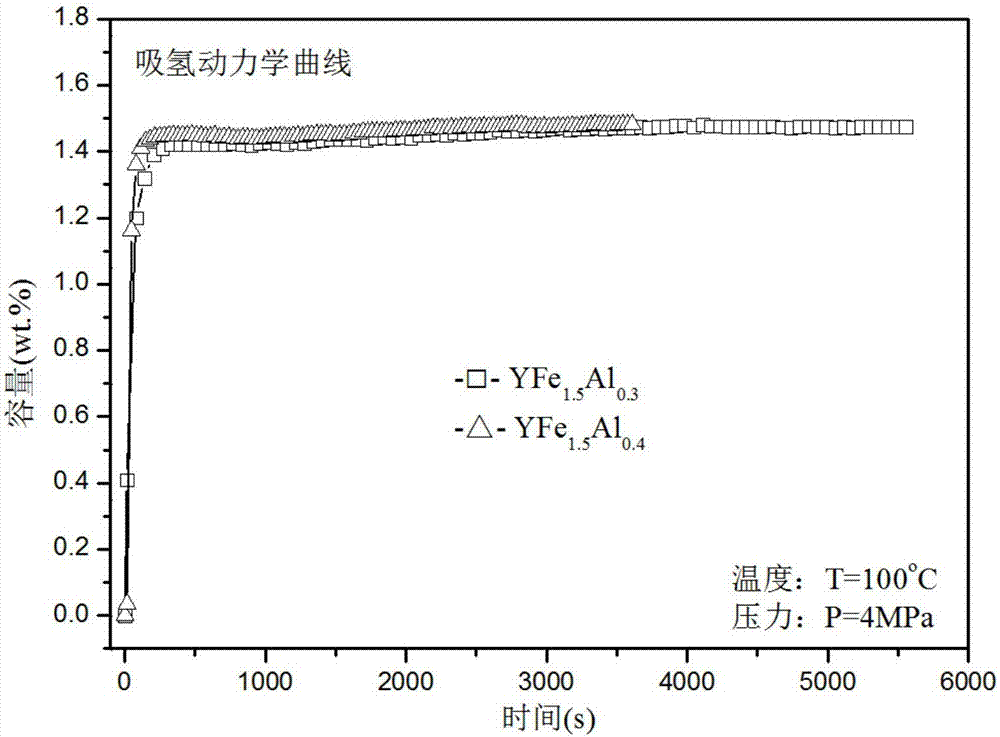

[0044] (1) Put yttrium block, iron block and aluminum block (purity not less than 99wt.%) according to molecular formula YFe 1.5 Al 0.4 , that is, the yttrium block, the iron block and the aluminum block are uniformly mixed according to the mass fraction of 48.46%, 45.66% and 5.88%, melted in an electric arc melting furnace at 1400 ° C for 5 minutes, and the alloy ingot is obtained after cooling;

[0045] (2) Turn over the alloy ingot obtained in step (1), and re-melt and cool, so that the smelting is repeated 5 times. The re-melting is carried out in an electric arc melting furnace, and the vacuum degree in the vacuum chamber of the arc melting furnace is 1.0x10 -3 Pa, temperature and time are the same as step (1). The obtained ingot is placed in an argon protective atmosphere at a temperature of 22-25°C.

[0046] (3) Crushing the ingot into a powder state in an argon protective atmosphere to obtain a yttrium-iron-aluminum alloy hydrogen storage material with uniform compo...

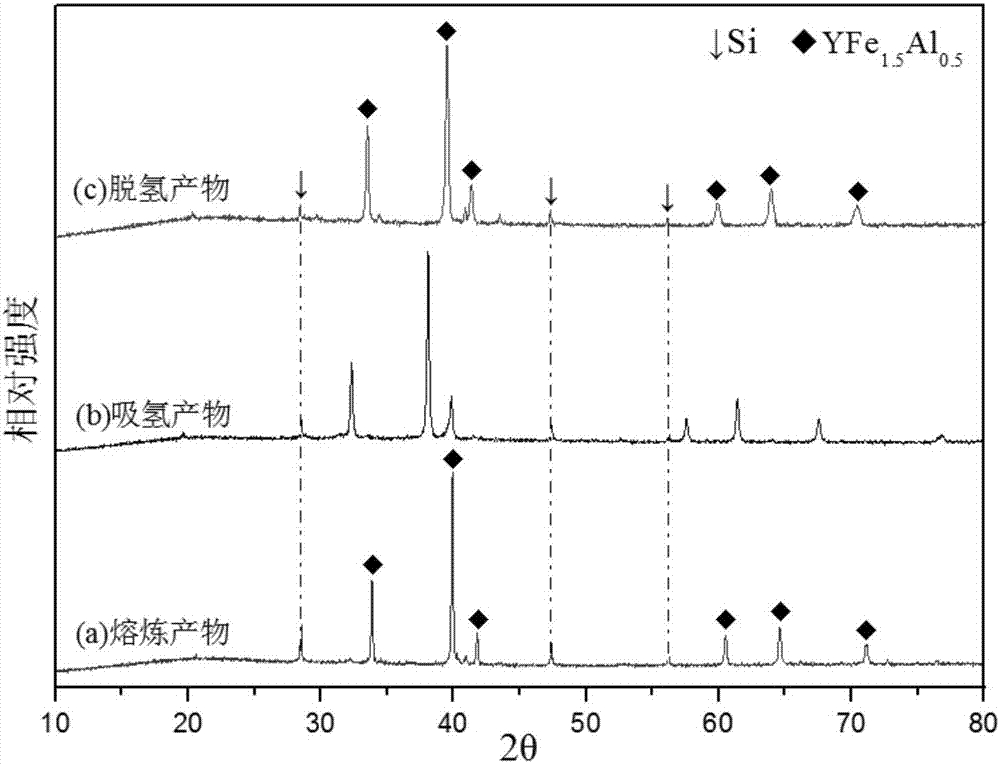

Embodiment 3

[0049] (1) Put yttrium block, iron block and aluminum block (purity not less than 99wt.%) according to molecular formula YFe 1.5 Al 0.5 , that is, yttrium block, iron block and aluminum block are mixed uniformly according to the mass fraction of 47.76%, 45% and 7.24%, and melted in an electric arc melting furnace at 1400 ° C for 5 minutes, and the alloy ingot is obtained after cooling; the vacuum chamber of the electric arc melting furnace The vacuum is 1.0x10 -3 Pa.

[0050] (2) Turn over the alloy ingot obtained in step (1), and re-melt and cool, so that the smelting is repeated 5 times. The remelting is carried out in an electric arc melting furnace, and the vacuum degree in the vacuum chamber of the arc melting furnace is 1.0x10 -3 Pa, temperature and time are the same as step (1). The obtained ingot is placed in an argon protective atmosphere at a temperature of 22-25°C.

[0051] (3) Crushing the ingot into a powder state in an argon protective atmosphere to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com