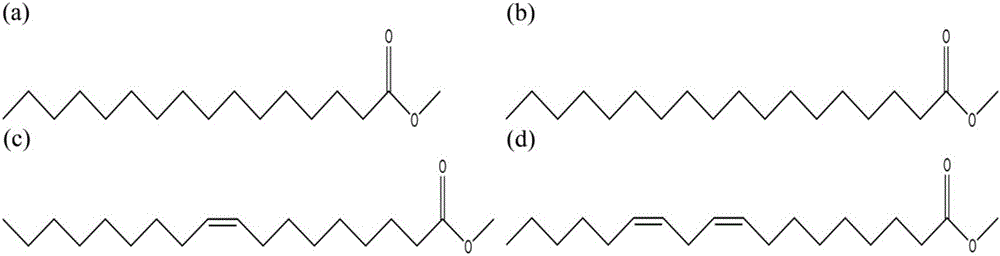

Intra-tower pump suction type high vacuum distillation method and device for precise separation of C16-C22 fatty acids

A technology for precision separation and fatty acid, which is applied in the field of pump-suction high vacuum rectification in the tower, which can solve the problem of hindering the research and application of high-purity fatty acid methyl ester, can not solve the problem of pressure drop in high vacuum rectification tower, and increase the production cost of heat-sensitive substances and other problems, to achieve the effect of lower heating temperature, lower equipment cost, and shorter residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The raw material used in this example is a high acid value vegetable oil, and the acid value is 23.6 mgKOH / g as determined by the national standard GB-T5530-2005 method.

[0064] (1) Pretreatment of vegetable oil, the specific steps are:

[0065] (a) Take the ionic liquid [Bmim]Br-CuCl, vegetable oil and methanol with a mass ratio of 1:2:34 into the reaction vessel; place the reaction vessel in a 50°C water bath, and stir the mixture in the vessel until Vegetable oil and methanol fully react under the catalysis of ionic liquid [Bmim]Br-CuCl to produce a mixture of fatty acid methyl esters with an acid value of less than 1;

[0066] (b) After the reaction, the ionic liquid and the mixture of fatty acid methyl esters with an acid value of less than 1 are separated by decantation, and the mixture of fatty acid methyl esters is biodiesel;

[0067] (c) Rotary evaporate the separated [Bmim]Br-CuCl ionic liquid at 90°C to remove a small amount of methanol and water, and then recycle i...

Embodiment 2

[0075] The raw material used in this example is a certain high acid value vegetable oil of Example 1.

[0076] (1) Pretreatment of vegetable oil, the specific steps are:

[0077] (a) Take CaO, vegetable oil and methanol with a mass ratio of 1:2:28 into the reaction vessel; place the reaction vessel in a 100°C water bath, and stir the mixture in the vessel until the vegetable oil and methanol are catalyzed by CaO Fully react to obtain a mixture of fatty acid methyl esters;

[0078] (b) After the reaction, the pretreatment products of various fatty acid methyl ester mixtures are separated from the mixture in the reaction vessel, and the multiple fatty acid methyl ester mixtures are biodiesel;

[0079] (c) The remaining material in the reaction vessel is rotary evaporated at 100° C. to recover a small amount of methanol and water, and then recover and treat.

[0080] (2) High vacuum fine separation of C16~C18 fatty acid methyl esters, the specific steps are:

[0081] (a) Take the mixture o...

Embodiment 3

[0087] The raw material used in this example is a certain waste corn oil, and the acid value is 10.1 mgKOH / g determined by the national standard GB-T5530-2005 method.

[0088] (1) Pretreatment of waste corn oil, the specific steps are:

[0089] (a) Take the ionic liquid [BTBD]OH with a mass ratio of 1:6:20, waste corn oil, and methanol into the reaction vessel; place the reaction vessel in a 55°C water bath, and stir the mixture in the vessel until Vegetable oil and methanol fully react under the catalysis of ionic liquid [BTBD]OH to produce a mixture of fatty acid methyl esters with an acid value of less than 1.

[0090] (b) After the reaction, the ionic liquid and the mixture of fatty acid methyl esters with an acid value of less than 1 are separated by decantation, and the mixture of fatty acid methyl esters is biodiesel;

[0091] (c) The separated [BTBD]OH ionic liquid is rotary evaporated at 100℃ to remove a small amount of methanol and water, and then recycled and reused; the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com