Manufacturing method and application of shape-memory polymer leather wrinkle-removing finishing material

A memory polymer, leather technology, applied in polyurea/polyurethane coating, application, leather drying and other directions, can solve the problems of leather clothing storage mode crease, lack of anti-wrinkle performance, difficult to remove wrinkles, etc., to achieve obvious anti-wrinkle and anti-wrinkle Wrinkle effect, excellent air permeability, good low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for making a shape-memory polymer leather anti-wrinkle finishing material,

[0037] 1. Use DMF (N,N-dimethylformamide) Molecular sieves were dried for 24 hours to obtain dry DMF. Solid PCL was placed in a drying oven for heating and melting to obtain liquid PCL. 10 g of liquid PCL (polycaprolactone 2000) was placed in a container with mechanical stirring, argon protection, a condenser tube and a thermometer. In a four-neck flask, vacuum dehydration was carried out at 120°C in a water bath for 1h, then dry 60g DMF and 3.75g MDI (diphenylmethane diisocyanate) were added under the condition of argon protection, and the reaction was stirred at 75°C for 2h to obtain Prepolymer, take out a small amount of prepolymer for -NCO titration;

[0038] 2. Add 0.9g 1,4-BDO (1,4-butanediol) and 38g DMF to the prepolymer obtained in step 1, carry out chain extension reaction at 75°C for 2 hours, and obtain a compound with a solid content of 15 % linear SMPU solution (linear s...

Embodiment 2

[0041] Example 2: The shape-memory polymer selected in this embodiment is shape-memory polylactic acid, and the preparation method of the coating material is implemented according to the following steps:

[0042] Pour 5g of polylactic acid (PLA) and 0.5g of benzophenone into the reagent bottle, add 50g of dichloromethane solvent, and after sealing, stir on a magnetic stirrer at a speed of 300r / min for 20h-24h. The obtained solution is evenly coated on leather of suitable size, and dried at room temperature or in an oven at 40°C-50°C for 15h-24h to obtain a wrinkle-resistant leather product coated with a shape memory polymer.

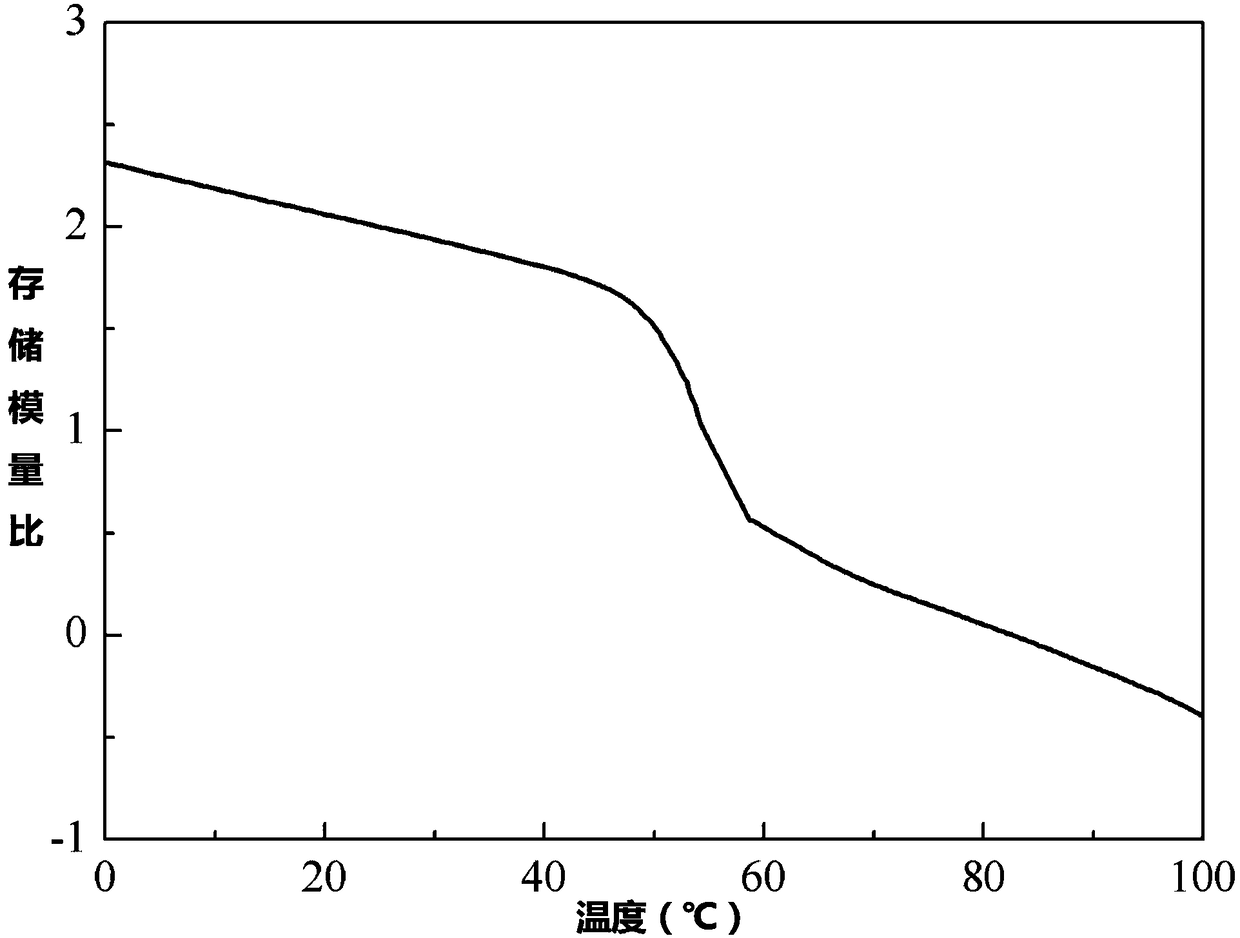

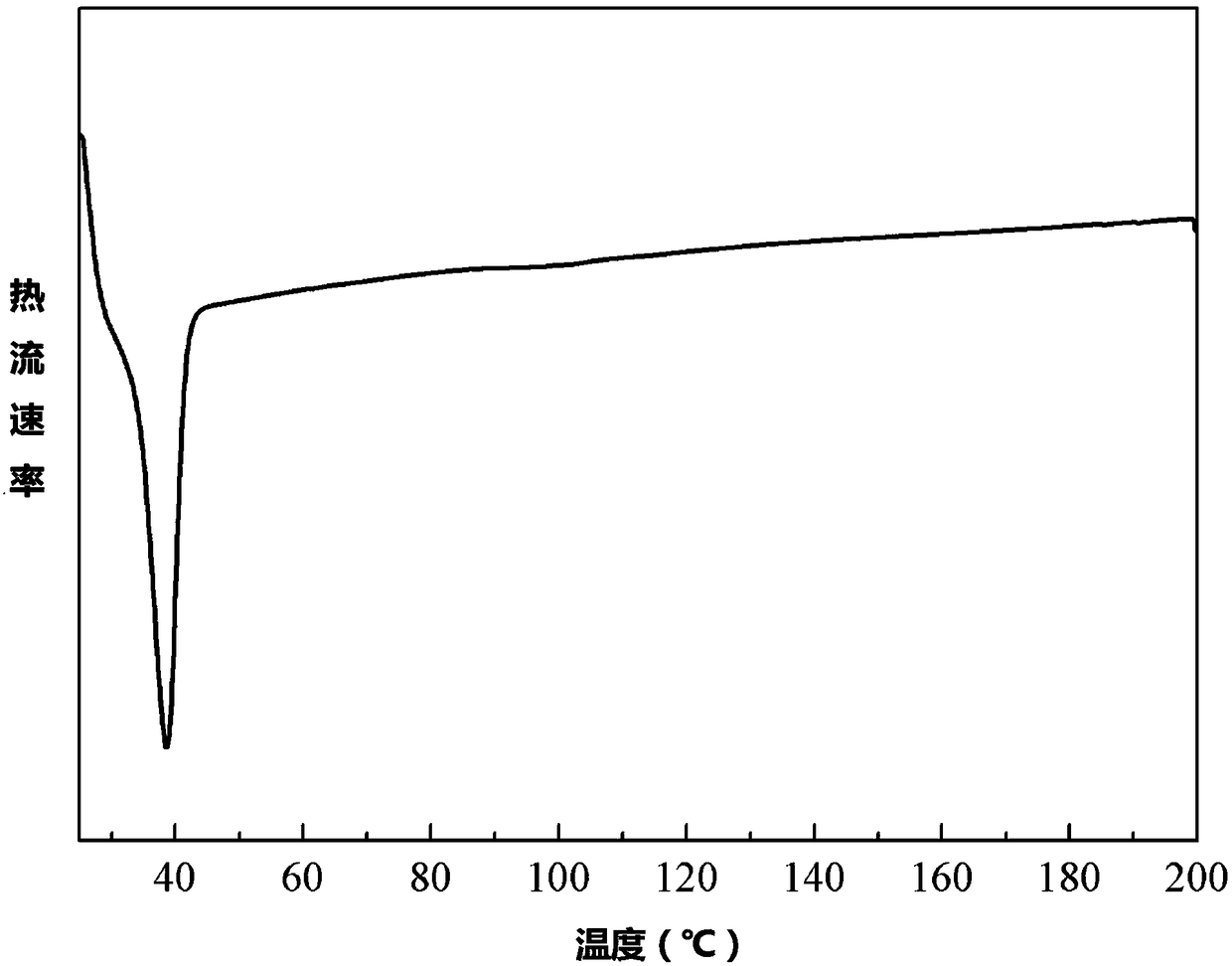

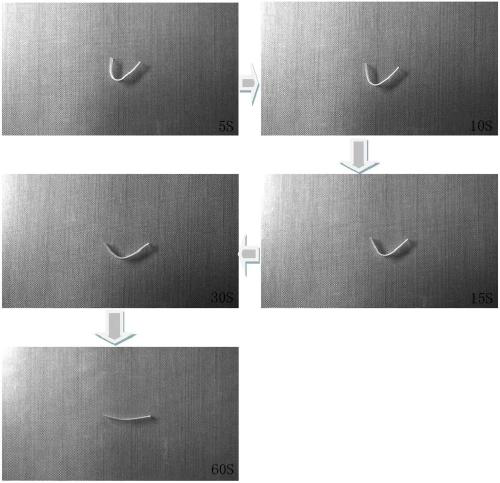

[0043] The measured glass transition temperature is around 55°C. Heat the flat leather coated with shape-memory polylactic acid to about 60°C, fold it in half, fix its shape and cool it to room temperature, and then heat it again to about 60°C, after about 3 minutes, you can find that the folded leather gradually unfolds , until the crease disappears an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com