A sandwich porous roof matrix block and its preparation method

A matrix block and sandwich technology, applied in the field of value-added utilization of agricultural waste, can solve the problems of unfavorable mass transportation, hoisting, large changes in nutrient content, poor quality stability, etc., achieve good water absorption and water retention, and small production investment , the effect of strong molding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

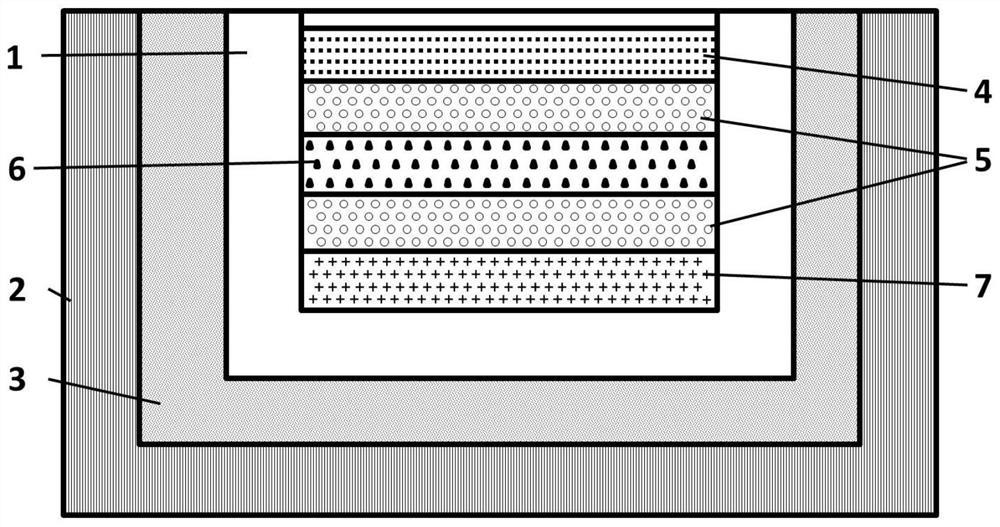

[0040]Firstly, after drying the whole plant of rice straw and dusting off the sand, it is pulverized and sieved with a pulverizer to obtain straw powder with a size of 50 mesh, and spread it evenly on the bottom of the graphite crucible 1 . In addition, straw powder, 100-mesh aluminum powder, ferrosilicon powder, potassium nitrate powder, sodium nitrate powder and sodium fluoride powder were uniformly mixed according to the mass ratio of 40:45:12:100:78:2, and the obtained mass was 20 times the first mixed powder 5 of the straw powder 7, and put it into the graphite crucible 1 on top of the straw powder 7. Take another straw powder, 100-mesh aluminum powder, ferrosilicon powder, potassium nitrate powder, sodium nitrate powder and sodium fluoride powder and mix them uniformly according to the mass ratio of 87:45:12:100:78:2 to obtain the mass Be the second mixed powder 6 of 20 times of the straw powder 7, and put it into the first mixed powder 5 in the graphite crucible 1. Con...

Embodiment 2

[0042] Firstly, after drying the whole plant of corn stalks and dusting off the sand, they were crushed and sieved with a pulverizer to obtain 100-mesh straw powder, which was evenly spread on the bottom of the graphite crucible 1 . In addition, straw powder, 200-mesh aluminum powder, ferrosilicon powder, potassium nitrate powder, sodium nitrate powder and sodium fluoride powder were uniformly mixed according to the mass ratio of 40:54:28:109:85:4, and the obtained mass was 20 times the first mixed powder 5 of the straw powder 7, and put it into the graphite crucible 1 on top of the straw powder 7. Take another straw powder, 200-mesh aluminum powder, ferrosilicon powder, potassium nitrate powder, sodium nitrate powder and sodium fluoride powder and mix them uniformly according to the mass ratio of 87:54:28:109:85:4 to obtain the mass Be the second mixed powder 6 of 20 times of the straw powder 7, and put it into the first mixed powder 5 in the graphite crucible 1. Configure t...

Embodiment 3

[0044] Firstly, after drying the whole plant of wheat straw and dusting off the sand, it is pulverized and sieved with a pulverizer to obtain straw powder with a size of 80 meshes, which is evenly spread on the bottom of the graphite crucible 1 . Another straw powder, 150-mesh aluminum powder, ferrosilicon powder, potassium nitrate powder, sodium nitrate powder and sodium fluoride powder were uniformly mixed according to the mass ratio of 40:50:20:105:82:3, and the obtained mass was 20 times the first mixed powder 5 of the straw powder 7, and put it into the graphite crucible 1 on top of the straw powder 7. Take another straw powder, 150-mesh aluminum powder, ferrosilicon powder, potassium nitrate powder, sodium nitrate powder and sodium fluoride powder and mix them uniformly according to the mass ratio of 87:50:20:105:82:3 to obtain the mass Be the second mixed powder 6 of 20 times of the straw powder 7, and put it into the first mixed powder 5 in the graphite crucible 1. Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com