A purification system and method for producing acetylene from natural gas

A natural gas and acetylene technology, applied in the field of removing impurities in acetylene produced by natural gas, can solve the problems of difficult disposal of waste acid and large consumption of acid and alkali, achieve uniform and gentle absorption and regeneration conditions, reduce solvent loss, and equipment Effects with low material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

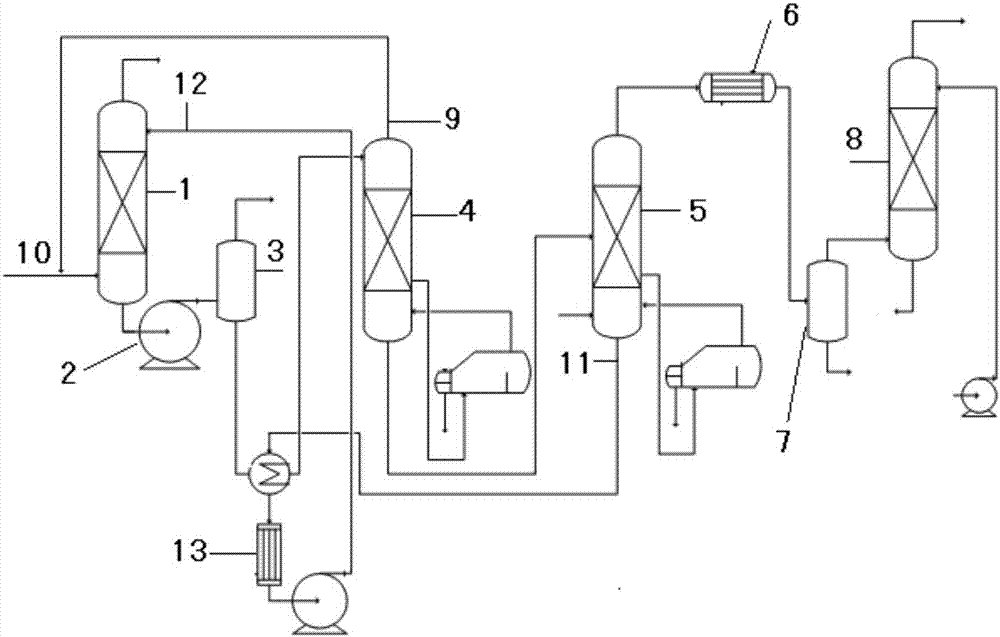

[0051] This embodiment relates to a purification system for producing acetylene from natural gas, and its structural diagram is as follows figure 1 :

[0052] It includes an acetylene absorption tower 1, a flash tank 3, a hydrogenation reactor 5, and a carbonization tower 8 connected in succession with absorption liquid; the liquid outlet 11 on the hydrogenation reactor is connected to the liquid inlet of the acetylene absorption tower 12.

[0053] A regeneration tower 4 is arranged between the flash tank 3 and the hydrogenation reactor 5, and the gas outlet 9 on the regeneration tower 4 is connected to the gas inlet 10 of the acetylene absorption tower.

[0054] A liquid cooling device 13 is provided between the liquid outlet 11 of the hydrogenation reactor 5 and the liquid inlet 12 of the acetylene absorption tower.

[0055] A cooler 6 and a gas-liquid separator 7 connected in sequence are also provided between the hydrogenation reactor 5 and the carbonization tower 8 .

Embodiment 2

[0057] This embodiment relates to a method for purifying acetylene produced by natural gas cracking, comprising the steps of:

[0058] 1) The raw material gas obtained by partial oxidation of natural gas is passed into the acetylene absorption tower, partially absorbed by the absorption liquid, and the gas that cannot be absorbed is discharged out of the acetylene absorption tower; the space velocity of the raw material gas is 600Nm 3 / h, the pressure in the absorption tower is 0.45MPa, and the gas composition is to contain 7.8% (molar concentration, the same below) C 2 h 2 , 4.9%CH 4 , 0.2%C 2 h 4 , 25.7% CO, 0.9% N 2 , 55.9%H 2 , 3.3%CO 2 , 1.2% higher alkynes and other small amounts of C 6 + the above components. The absorption liquid is a mixed solvent of 1,3-diacetamide imidazole bis(trifluoromethanesulfonyl)imide salt ionic liquid and propylene carbonate, and its flow rate is 5m 3 / h, wherein the mass content of propylene carbonate is 50%, and the rest is 1,3-d...

Embodiment 3

[0065] This embodiment relates to a method for purifying acetylene produced by natural gas cracking, comprising the steps of:

[0066] 1) The raw material gas obtained by partial oxidation of natural gas is passed into the acetylene absorption tower, partially absorbed by the absorption liquid, and the gas that cannot be absorbed is discharged out of the acetylene absorption tower; the space velocity of the raw material gas is 600Nm 3 / h, the pressure in the absorption tower is 0.45MPa, and the gas composition is to contain 7.8% (molar concentration, the same below) C 2 h 2 , 4.9%CH 4 , 0.2%C 2 h 4 , 25.7% CO, 0.9% N 2 , 55.9%H 2 , 3.3%CO 2 , 1.2% higher alkynes and other small amounts of C 6 + the above components. The absorption liquid is a mixed solvent of 1,3-diacetamide imidazole bis(trifluoromethanesulfonyl)imide salt ionic liquid and propylene carbonate, wherein the mass content of propylene carbonate is 5%, and the rest is 1,3-di Acetamidoimidazole bis(triflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com