Preparation technique of aluminum hydroxide and aluminum oxide powder

A technology of aluminum oxide powder and aluminum hydroxide, which is applied in the preparation of aluminum hydroxide, the preparation of aluminum oxide/hydroxide, and the purification of aluminate/alumina/aluminum hydroxide, etc., can solve the difficulty of solid-liquid separation, filtration High resistance, high water content and other problems, to achieve the effect of simple raw materials, improved production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

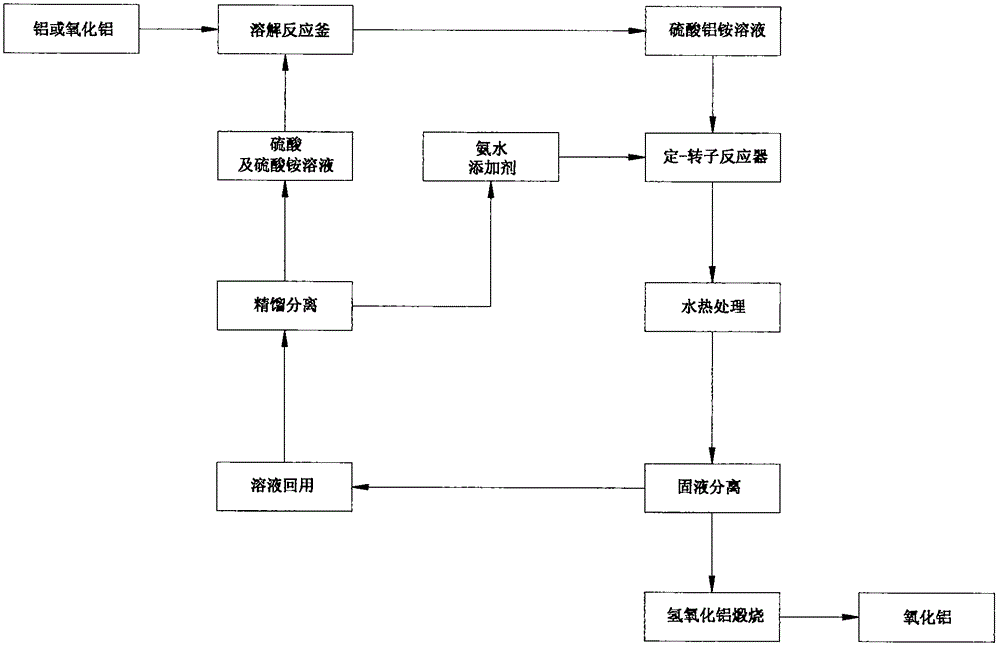

[0031] Using industrial aluminum ingot as raw material, the consumption is about 0.53t / h, reacting with ammonium sulfate solution containing dilute sulfuric acid at 50°C to obtain aluminum ammonium sulfate solution. Then react with recycled ammonia water and additive ethanol in a 3000rpm stator-rotor reactor to obtain aluminum hydroxide slurry. After the slurry is separated from solid and liquid, the liquid is separated and purified by rectification and reused. After the solid is washed and dried at low temperature, the intermediate product of high-dispersion aluminum hydroxide powder can be obtained, with an output of about 1.65t / h. After high-temperature calcination, highly dispersed high-purity alumina products are obtained, with an output of about 1t / h.

Embodiment 2

[0033] Recover the catalyst supported by alumina, with a processing capacity of about 7.6t / h, and react with ammonium sulfate solution containing dilute sulfuric acid at 200°C to obtain aluminum ammonium sulfate solution. Then react with recycled ammonia water and additive ethylene glycol in a 1200rpm stator-rotor reactor to obtain aluminum hydroxide slurry. The aluminum hydroxide slurry is hydrothermally treated at 120°C and then separated from solid and liquid, and the obtained liquid is further rectified, separated and purified for reuse. After the solid obtained from solid-liquid separation is washed and dried at low temperature, the intermediate product, high-dispersion aluminum hydroxide powder, can be obtained, with a production capacity of about 13t / h. After calcining at high temperature, a highly dispersed alumina product is obtained, with an output of about 7t / h.

Embodiment 3

[0035] Recover the catalyst supported by alumina, with a processing capacity of about 16.2t / h, and react with ammonium sulfate solution containing dilute sulfuric acid at 160°C to obtain aluminum ammonium sulfate solution. Then react with recycled ammonia water and additive acetone in a 100rpm stator-rotor reactor to obtain aluminum hydroxide slurry. The aluminum hydroxide slurry is hydrothermally treated at 200°C and then separated from solid and liquid, and the obtained liquid is further rectified, separated and purified for reuse. After the solid obtained from solid-liquid separation is washed and dried at low temperature, the intermediate product, high-dispersion aluminum hydroxide powder, can be obtained, with an output of about 27t / h. After calcining at high temperature, a highly dispersed alumina product is obtained, with an output of about 15t / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com