Method and device for preparing high-purity nano boron powder by argon-hydrogen hot plasma method

A technology of plasma and nano-boron, which is applied in the field of high-purity nano-boron powder preparation by plasma method, can solve the problems of difficult control of particle size and purity, complex post-treatment purification process, and harsh process conditions, and achieve easy large-scale production, The effect of high purity and good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

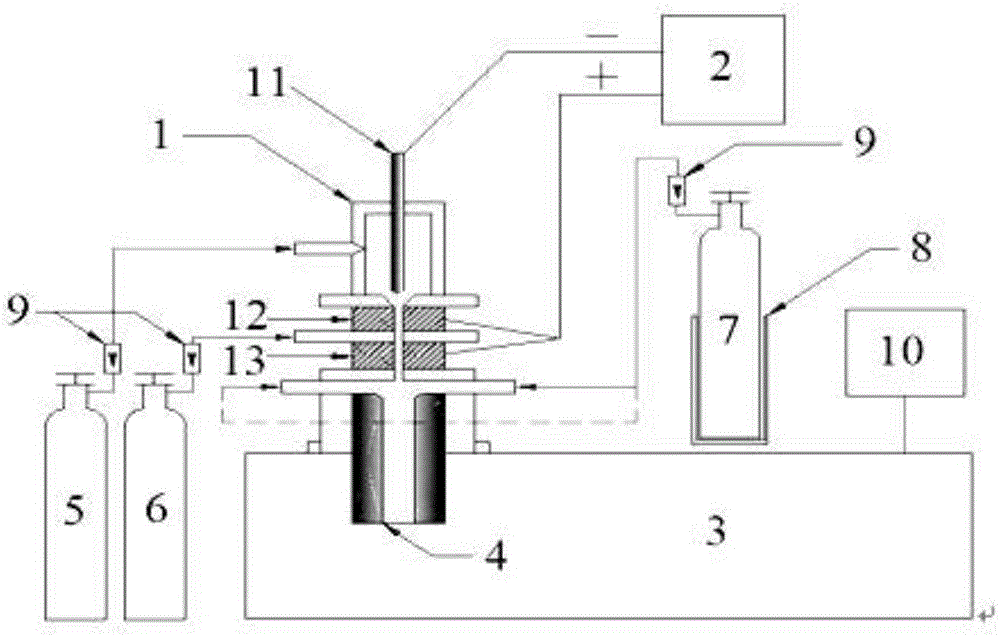

Method used

Image

Examples

Embodiment 1~3

[0042] Start the plasma power supply and generator, first use the discharge argon to replace and clean the device, and then gradually add hydrogen to the discharge gas to the required flow rate. After the device is stabilized, BCl is introduced from the upper part of the reactor 3 The steam is mixed with the high temperature plasma jet. Under the action of hydrogen plasma in the reaction tube, a reduction reaction occurs. During the experiment, hydrogen, BCl 3 , The argon flow ratio is maintained at 5:2.5:1.5; according to the BCl in Table 1 3 Adjust the flow rate of hydrogen and argon. By changing the discharge power, the yield of elemental boron was examined. The boron powder obtained from the powder collector is weighed with a balance, and divided by the mass of boron in the raw materials consumed by the reaction to obtain the yield of elemental boron. The results are shown in Table 1.

[0043] Table 1 Yield of elemental boron under different discharge conditions

[...

Embodiment 4

[0047] Start the plasma power supply and generator, first use the discharge argon to replace and clean the device, and then gradually add hydrogen to the discharge gas to the required flow rate. After the device is stabilized, BCl is introduced from the upper part of the reactor 3 The steam is mixed with the high temperature plasma jet. Under the action of hydrogen plasma in the reaction tube, a reduction reaction occurs. During the experiment, hydrogen, BCl 3 , argon gas flow maintained at 20m 3 / h, 10kg / h, 2m 3 / h. The discharge power is 200kW, the average temperature of the plasma jet is 4000-6000°C, the temperature of the mixed gas during the reduction reaction is 3000°C, and the running time is 60min. Check the yield of elemental boron. The boron powder obtained from the powder collector is weighed with a balance, and divided by the mass of boron in the raw materials consumed by the reaction, the yield of elemental boron is 60%.

Embodiment 5

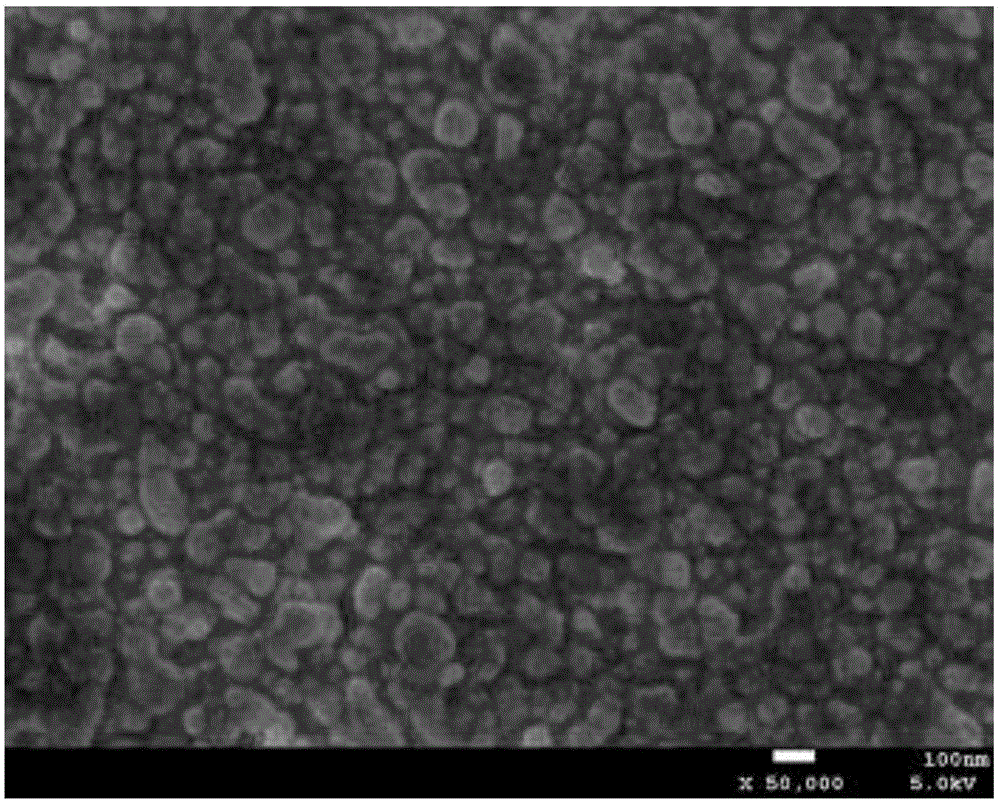

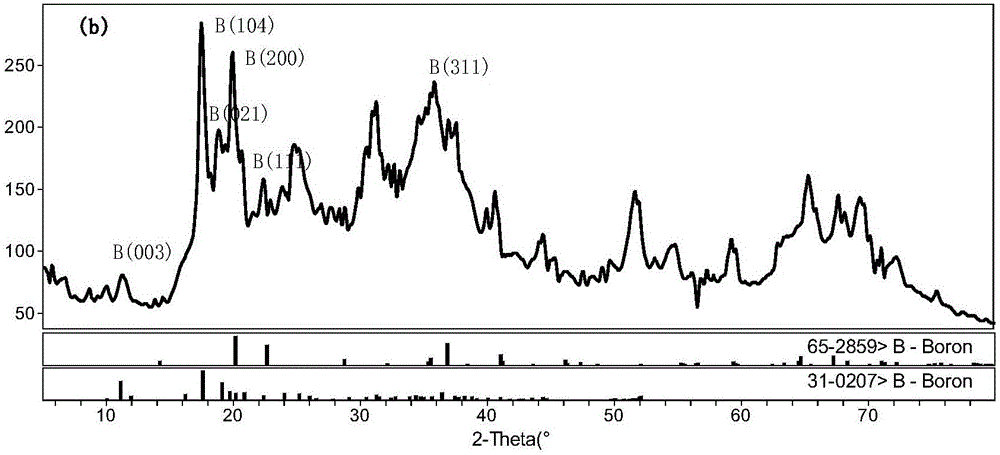

[0049] In order to analyze the purity of the obtained boron powder, the product of Example 1 was sent to the Analysis and Testing Center of the National Institute of Nonferrous Metals for elemental analysis. The obtained results are shown in Table 2, and the B content is >98%. Among them, Mg, Al, Ca, Ti, Cr, Fe, Ni, Zn, Si and other elements are given by inductively coupled plasma mass spectrometry (ICP-MS); Cu elements are given by inductively coupled plasma atomic emission spectroscopy (ICP-AES) It is given that C elements are analyzed by high-frequency fusion infrared detection method, O and N elements are detected by pulse infrared thermal conductivity method, and B elements are obtained by subtraction method.

[0050] The element analysis result of table 2 boron powder

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com