Preparation method and application of carbon-fiber-reinforced macromolecule-based composite

A polymer-based, composite material technology, applied in the coating and other directions, can solve problems such as nanoparticle agglomeration, and achieve the effects of simple and easy-to-control process, short preparation cycle, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a carbon fiber reinforced polymer matrix composite material, comprising the following steps:

[0030] Step 1: Weigh 0.5~5gA (A can be potassium permanganate, ammonium molybdate, sodium tungstate, zinc chloride, copper chloride, titanium chloride, aluminum chloride and other salts required for the synthesis of metal oxides) , dissolved in 40-80ml of B solvent (can be water, ethanol, propanol and ethylene glycol, etc.), configured into a C solution with a molar concentration of 0.01-5mol / L, and adjusted its pH to be acidic;

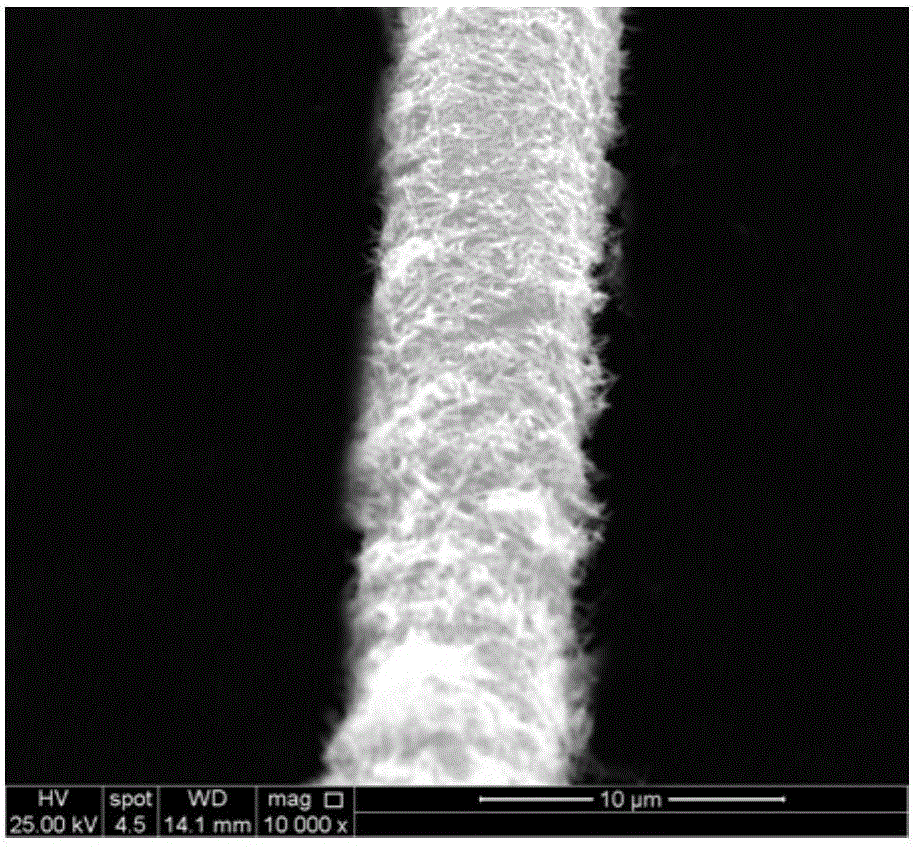

[0031] Step 2: Put the carbon arrangement in an acetone solution and ultrasonically clean it for 2-10 hours, take it out, wash it with deionized water, and dry it. Then place the dried carbon in 0.1-2mol / L potassium permanganate solution and soak for 12-36 hours (the purpose of soaking in potassium permanganate solution is to remove the organic matter on the surface of the carbon fiber. Of course, it can also be treated with ni...

Embodiment 2

[0036] Step 1: Combine 0.01-5mol / L A solution (A can be the salt required for the synthesis of sulfides such as ammonium molybdate, sodium tungstate, sodium metasquarate, cupric chloride, ferric chloride) and 0.01-5mol / L The B solution (B can be organic or inorganic sulfur source solutions such as thioacetamide, sodium sulfide, copper reagent, sodium diethyldithiocarbamate, sulfuric acid, ammonium peroxodisulfate) is uniformly mixed, and its pH value is adjusted to Acidic, to obtain a mixture C;

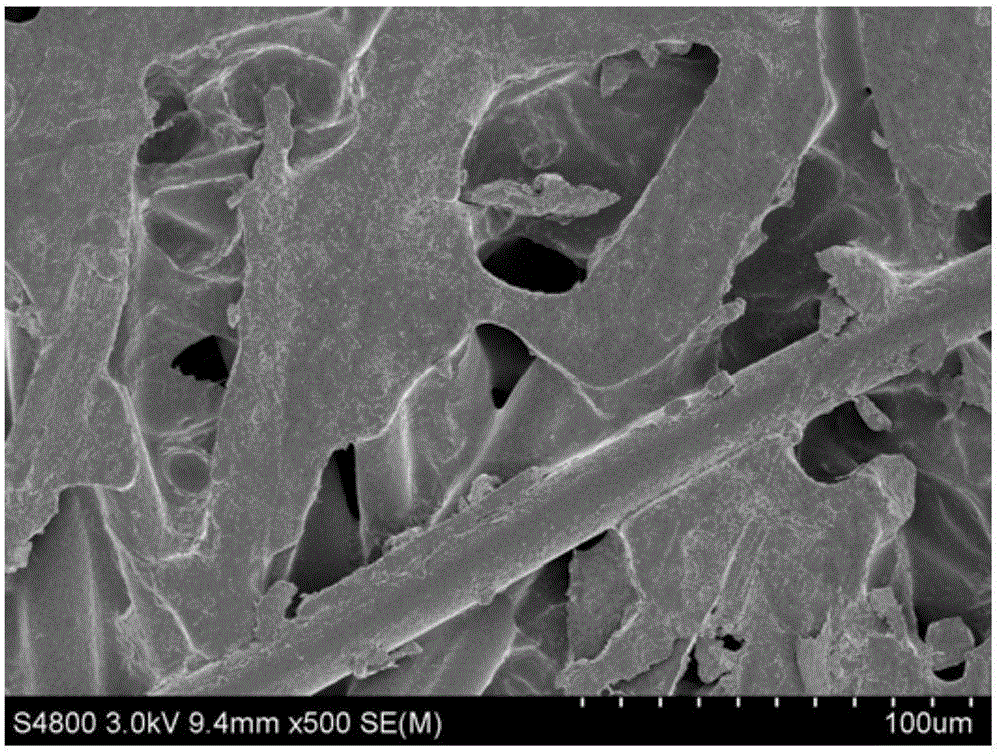

[0037] Step 2: Weigh 0.1g-5g of carbon nanofibers and place them in a molding machine, and let them stand for 10min-60min under a pressure of 2Mpa-15Mpa to obtain a carbon nanofiber sheet D with a thickness of 0.5mm-10mm. Wash with ethanol and deionized water for 3 to 6 times respectively, and dry at 60-100°C;

[0038] Step 3: Transfer the C solution into the reaction kettle, and add the nano-carbon fiber sheet D in step 2, seal it and place it in a hydrothermal induction heating de...

Embodiment 3

[0043] Step 1: Weigh 0.5-5g of A (A can be the salt required for the synthesis of non-metallic oxides such as orthosilicate, calcium carbonate, etc.), dissolve it in 40-80ml of B solvent (it can be water, ethanol, propanol and ethanol Diol, etc.), configured as a C solution with a molar concentration of 0.01 to 5 mol / L, and adjusted its pH to be alkaline;

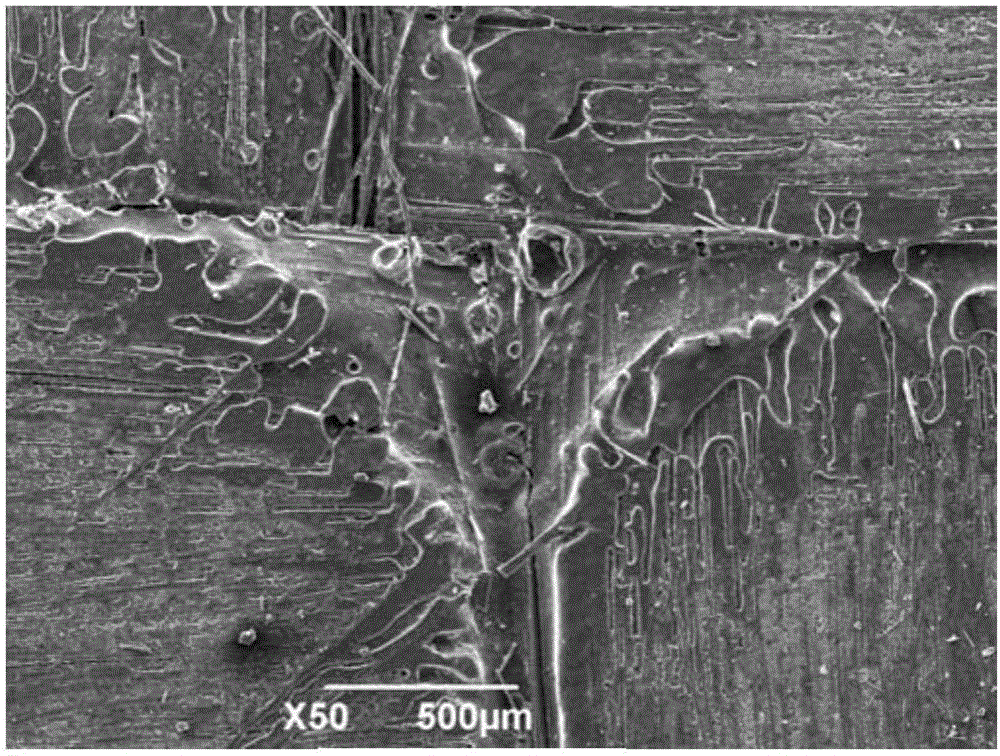

[0044] Step 2: Put the chopped carbon fiber (100um-800um in length, 10-20um in diameter) in an acetone solution for ultrasonic cleaning for 2-10 hours, take it out, wash it with deionized water, and then dry it. Then soak the dried chopped carbon fibers in 0.1-2 mol / L nitric acid solution for 12-36 hours. Finally, the soaked chopped carbon fibers are cleaned and dried with deionized water;

[0045] Step 3: Weighing 1g to 6g of the chopped carbon fiber in step 2 and dissolving it in 50 to 200ml of water, and filtering it through a sand core funnel suction filter device to obtain a chopped carbon fiber sheet D with a certain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com