Method for preparing chitosan three-dimensional scaffold coated by graphene material

A three-dimensional stent, chitosan technology, applied in coatings, prostheses, medical science and other directions, can solve the problems of difficult to support tissue and organ growth, low mechanical properties, difficult to modify, etc., to achieve large-scale production, simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

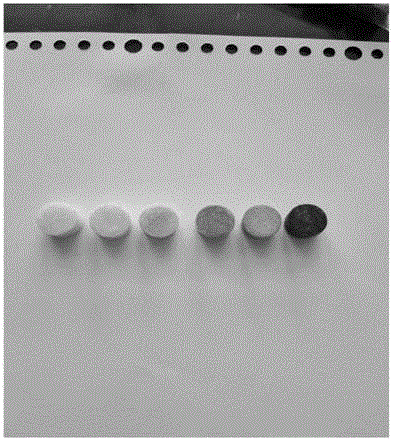

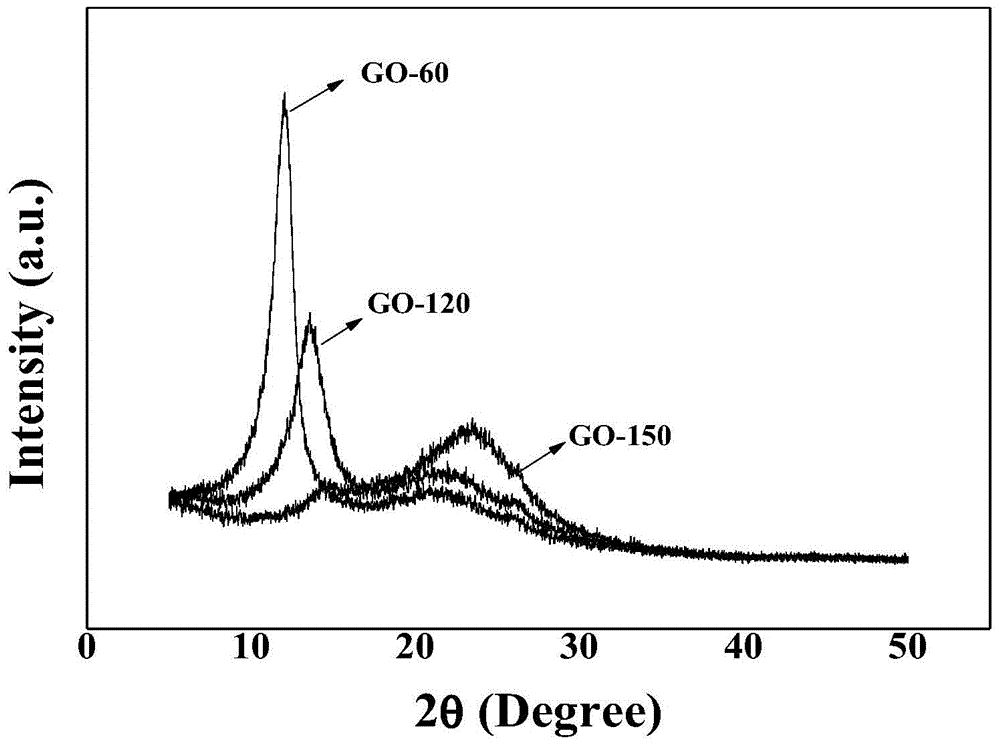

[0055] Composite materials with graphene coatings and chitosan three-dimensional scaffolds with different reduction degrees were prepared, and the specific experimental conditions were as follows:

[0056] 1) Dissolve chitosan powder in glacial acetic acid solution with a volume concentration of 2%, stir for 2 hours, make a chitosan solution with a concentration of 4% (w / v), ultrasonicate for 1 hour, let stand, and remove air bubbles .

[0057] 2) Inject the chitosan solution in step (1) into the mould, let it stand at 4°C for 12h, transfer to -20°C for 24h, and put it into a freeze dryer for 48h.

[0058] 3) Soak the porous scaffold in step (2) in 0.5% sodium hydroxide solution to neutralize the residual acetic acid, then soak and wash it with deionized water until it is neutral; freeze-dry it again.

[0059] 4) Utilize the improved Hummers method to prepare graphite oxide:

[0060] ① Dissolve 1.5g of sodium nitrate in 69ml of concentrated sulfuric acid, add 2g of graphite,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com