Preparation method of polyacrylonitrile-based precursor

A polyacrylonitrile-based, precursor technology, applied in the direction of spinning solution preparation, single-component synthetic polymer rayon, wet spinning, etc., can solve the problem of low strength of carbon fiber precursor, unstable performance, high filament breakage rate, etc. problems, to achieve the effect of maintaining stability, ensuring stability, and controlling the broken wire rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

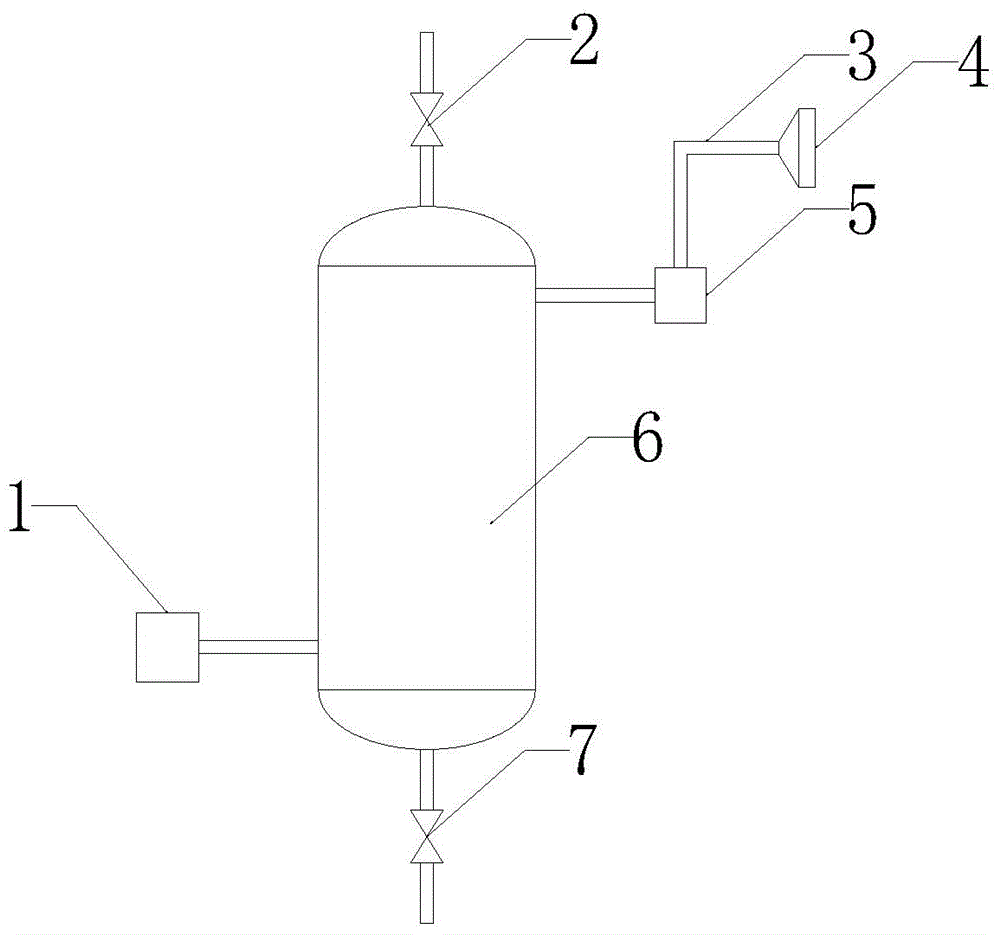

Image

Examples

Embodiment 1

[0018] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 38° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material. The filter assembly used first wets the filter, and the dimethyl sulfoxide solvent accounts for 40% of the volume of the filter. The temperature is controlled at 60°C, the vacuum degree of the filter vacuum is at -45KPa (gauge pressure), the speed of the metering pump is controlled so that the rising speed of the stock solution is 25mm / min, the discharge time of the bottom valve is controlled at 15min, and the discharge t...

Embodiment 2

[0026] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 38° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material. The filter assembly used first wets the filter, and the dimethyl sulfoxide solvent accounts for 40% of the volume of the filter. The temperature is controlled at 60°C, the vacuum degree of the filter is evacuated at -45KPa (gauge pressure), the speed of the metering pump is controlled so that the rising speed of the stock solution is 30mm / min, the discharge time of the bottom valve is controlled at 20min, and the discharg...

Embodiment 3

[0029] 1.1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt of the comonomer %, put dimethyl sulfoxide (DMSO) into the reactor as a solvent, and react at a constant temperature of 38° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material. The filter assembly used first wets the filter, and the dimethyl sulfoxide solvent accounts for 40% of the volume of the filter. The temperature is controlled at 60°C, the vacuum degree of the filter vacuum is at -45KPa (gauge pressure), the speed of the metering pump is controlled so that the rising speed of the stock solution is 22mm / min, the discharge time of the bottom valve is controlled at 12min, and the discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com