Recombined wood board adopting polyimide modified polyurethane adhesive and preparation method of polyimide modified polyurethane adhesive

A technology of polyurethane adhesive and polyimide, which is applied in the field of wood flooring, can solve problems such as ineffective effects, and achieve the effects of improving mechanical properties, superior economic benefits, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: A kind of recombined wood board adopting polyimide modified polyurethane adhesive, the recombined wood core board formed by pasting the fiber strips through the adhesive, and pressing, the surface of the recombined wood core board is provided with a paint layer, The side of the recombined wood core board is provided with side tenons and side grooves, and the adhesive is made of the following raw materials in parts by weight: 40 parts of polytetrahydrofuran glycol (molecular weight 2000), 4,4'-diphenylmethane 8.7 parts of isocyanate, 2.2 parts of pyromellitic dianhydride, 0.8 parts of simethicone, 0.06 parts of triethylenediamine, 20 parts of diisooctyl phthalate, 0.05 parts of p-toluenesulfonyl isocyanate , 0.05 parts of γ-aminopropyltriethoxysilane, and 0.05 parts of 3,5-di-tert-butyl-4-hydroxyphenylpropanoic acid octadecanoate.

[0042] Concrete preparation steps are:

[0043] 1) Weigh 400g of polytetrahydrofuran diol with a molecular weight of 2000 and...

Embodiment 2

[0054] Embodiment 2: A kind of recombined wood board adopting polyimide modified polyurethane adhesive, the recombined wood core board formed by pasting the fiber strips through the adhesive, and pressing, the surface of the restructured wood core board is provided with a paint layer, The side of the recombined wood core board is provided with side tenons and side grooves, and the adhesive is made of the following raw materials in parts by weight: 35 parts of tetrahydrofuran-ethylene oxide copolyglycol (molecular weight 3000), 12.2 parts of hexamethylene diisocyanate 5 parts of 3,3′,4,4′-biphenyltetraacid dianhydride, 1.6 parts of simethicone, 0.12 parts of triethylenediamine, 35 parts of diisooctyl phthalate, 0.13 parts of triethyl orthoformate, 0.3 parts of γ-(methacryloyloxy)propyltrimethoxysilane, and 0.08 parts of isooctyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate.

[0055] Concrete preparation steps are:

[0056] 1) Weigh 350g of tetrahydrofuran-ethylene oxide copolyg...

Embodiment 3

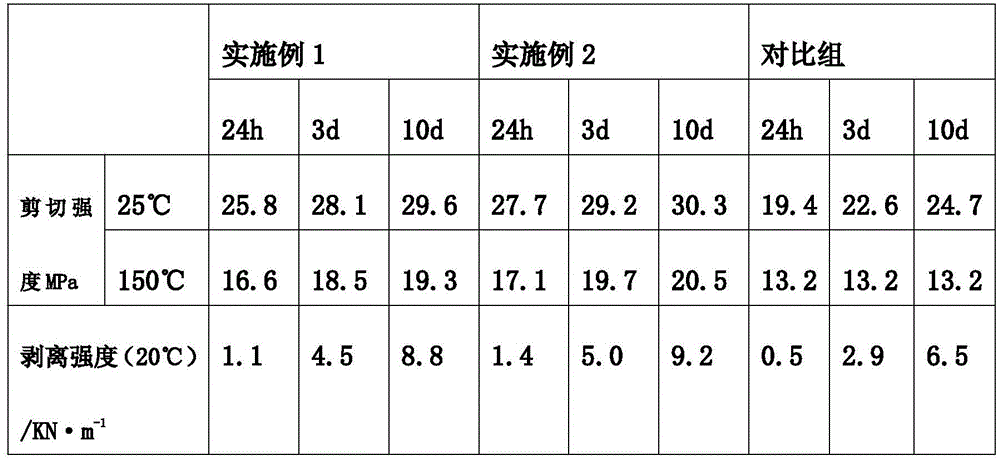

[0067] Embodiment 3: Comprehensive performance test of adhesive force.

[0068] Shear strength is measured according to GB7124-86;

[0069] Peel strength is measured according to GB / T7122-1996.

[0070] Get the wood floors of Examples 1 and 2, and then take the wood floors prepared by the polyurethane adhesive commonly used in the industry as a comparison group, and measure its shear strength and peel strength at room temperature for 24 hours, 3 days and 10 days, as shown in the table 1.

[0071] Table 1 Wood floor adhesion test

[0072]

[0073] It can be seen from Table 1 that the shear strength of Example 1 and Example 2 is significantly better than that of the comparison group at 25°C, and the shear strength at 150°C is also much better than that of the comparison group, and the effect is very significant. And the peel strength of Example 1 and Example 2 is also much better than that of the comparison group. It can be seen that the present invention not only has sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com