Method for preparing aromatic hydrocarbons by methane-plasma-activated oxygen-free aromatization

A plasma and aromatization technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, carbon compound catalysts, etc., can solve the problems of large equipment investment costs, high temperature, long routes, etc., to save costs and reduce Methane conversion temperature, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

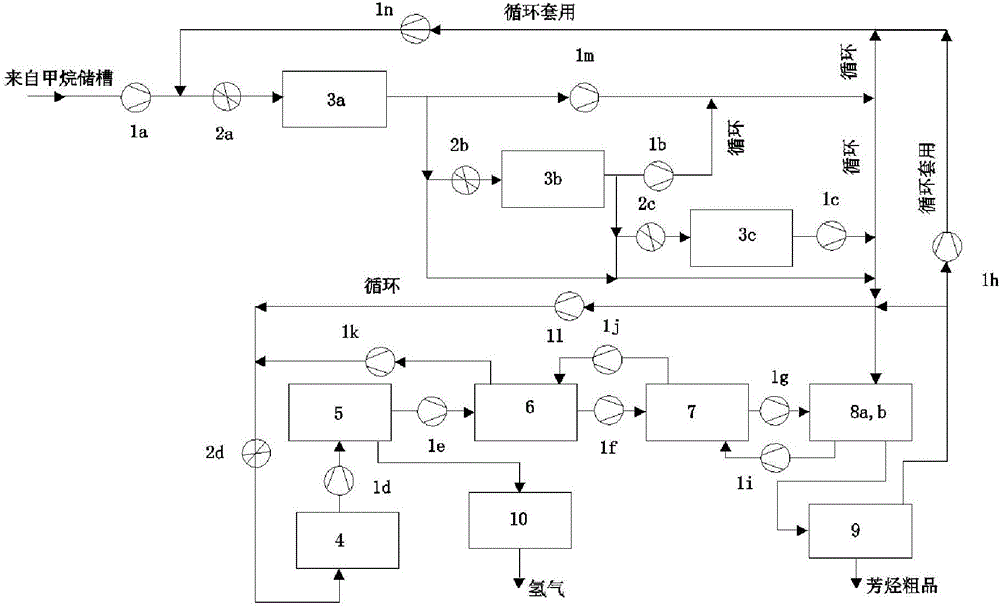

[0030]The raw material methane from the storage tank is heated by the air pump 1a at 0.1-0.12MPa respectively through the preheaters 2a, b, and c, and then passed into the multi-stage serial plasma activation reactors 3a, b, and c, with built-in quartz glass tubes, The power is 10w~1kW. In the reactor filled with catalyst, the catalyst contained is metal and oxide Ce, W, Mo, Ga, or supported, and the carrier is HZSM-5 zeolite molecular sieve. Plasma reactor 3a,b , c, if the methane in the mixed gas at the outlet does not reach the specified 10-20% single-pass conversion rate, it will be pumped back through the air pumps 1m, 1b, 1c and 1n respectively, and recycled; after multi-stage serial plasma activation reactions, the multi-pass total of methane will be controlled. The conversion rate is ~50%, on the premise of avoiding carbon deposition in the reactor, the obtained product gas contains ~50% methane, 0.1~20% ethane, 0.1~10% acetylene, 0.1~10% propane, and 0.1~10% butane 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com