Microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and molar mass, which is applied in the field of electronic materials and components, can solve the problems of high energy consumption, high sintering temperature, and non-compliance with low-carbon environmental protection, and achieve low sintering temperature, simple preparation process, and stable temperature characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

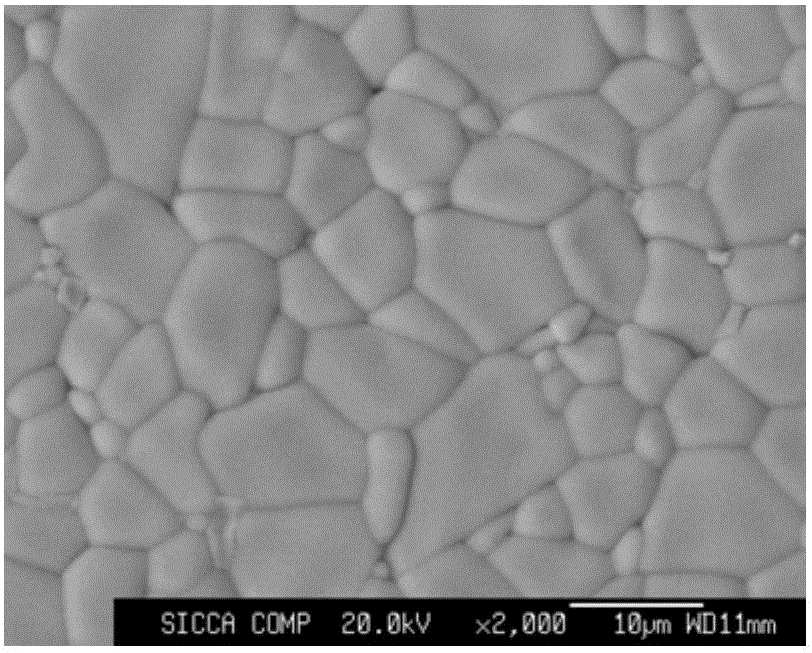

Image

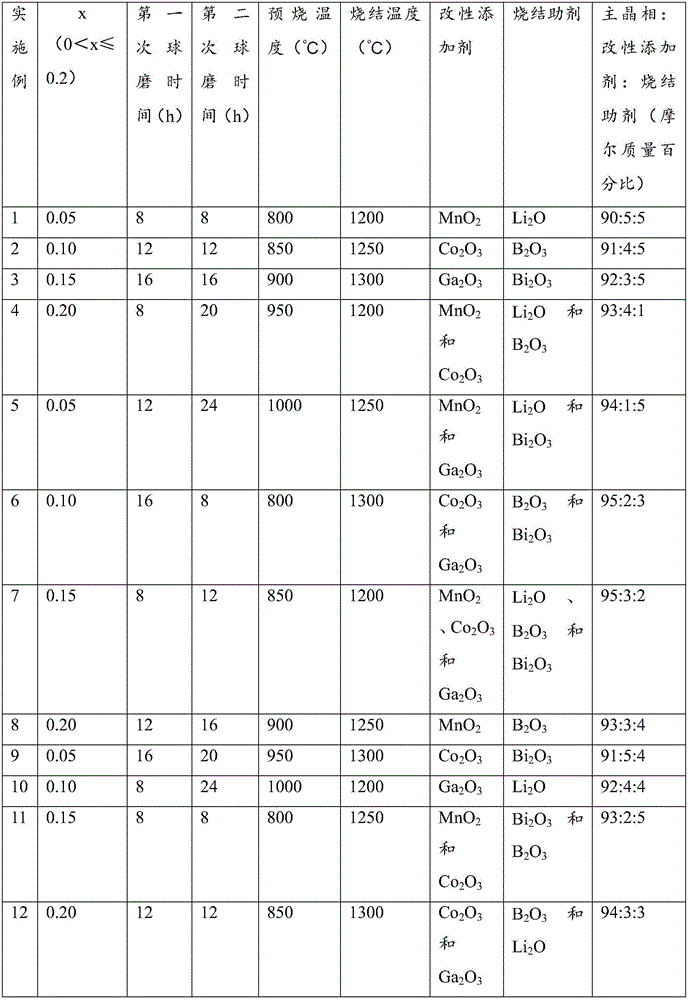

Examples

preparation example Construction

[0048] The invention provides a preparation method of microwave dielectric ceramics, comprising the following steps:

[0049] Step (1): Take ZrO according to the stoichiometric ratio of the chemical expression of the main crystal phase 2 , SnO 2 , MgO, Nb 2 o 5 、TiO 2 Carry out ball milling or sand milling for the first time and then dry to obtain the first mixture;

[0050] Above-mentioned, in step (1), preferably, with purity greater than 99% ZrO 2 , SnO 2 , MgO, Nb 2 o 5 , and TiO with a purity greater than 99.9% 2 It is the initial raw material; it is put into a ball mill for ball milling. The purpose of the first ball mill is to refine the powder and mix it evenly.

[0051] Preferably, the initial raw materials are put into a polyester tank, added with deionized water and zirconium balls, and milled on a planetary ball mill for several hours at a speed of 300-800 rpm.

[0052] It can be understood that the deionized water can also be alcohol.

[0053] Preferab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com