Environment-friendly water treatment flocculation material and preparation method thereof

An environmentally friendly water and flocculation technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor treatment effect, low treatment efficiency, high use cost, etc., and achieve good stability properties, simple preparation method, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 30 kg of polyacrylamide, 20 kg of polyferric chloride, 3 kg of peroxycarbonate, 3 kg of aluminum sulfate, 2 kg of isooctyl acrylate, 1 kg of 4-hydroxy-3-methoxybenzoic acid and 0.8 kg of ammonium bicarbonate kg, mix evenly, add to the reactor, add lignin 6kg, stir in the reactor at 8MPa, 110°C for 2 hours;

[0025] (2) Add 1 kg of ethylene glycol montan cerate and 1 kg of polydimethylsiloxane diquaternary ammonium salt in sequence, and stir at 40° C. for 10 minutes to obtain an environmentally friendly water treatment flocculation material.

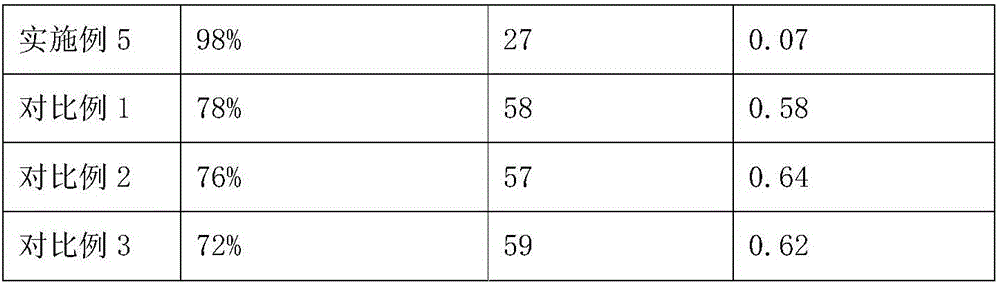

[0026] The performance test results of the prepared environmentally friendly water treatment flocculation materials are shown in Table 1.

Embodiment 2

[0028] (1) Weigh 30kg of polyacrylamide, 20kg of polyferric chloride, 3kg of peroxycarbonate, 3kg of aluminum sulfate, 2kg of isooctyl acrylate, 1kg of 4-hydroxy-3-methoxybenzoic acid, and 0.8 kg of ammonium bicarbonate. kg, N-(5-hydroxyethyl)nicotinamide nitrate 1kg and polyoxyethylene sorbitan monooleate 1kg, mix well, add to the reaction kettle, add lignin 6kg, in the reaction kettle 8MPa, 110℃ Stir for 2 hours;

[0029] (2) Add 1 kg of ethylene glycol montan cerate and 1 kg of polydimethylsiloxane diquaternary ammonium salt in sequence, and stir at 40° C. for 10 minutes to obtain an environmentally friendly water treatment flocculation material.

[0030] The performance test results of the prepared environmentally friendly water treatment flocculation materials are shown in Table 1.

Embodiment 3

[0032] (1) Weigh 40kg of polyacrylamide, 28kg of polyferric chloride, 6kg of peroxycarbonate, 5kg of aluminum sulfate, 5kg of isooctyl acrylate, 3kg of 4-hydroxy-3-methoxybenzoic acid, and 1.2 kg of ammonium bicarbonate. kg, N-(5-hydroxyethyl)nicotinamide nitrate 1kg and polyoxyethylene sorbitan monooleate 1kg, mix well, add to the reaction kettle, add lignin 11kg, in the reaction kettle 14MPa, 120℃ Down stirring for 4 hours;

[0033] (2) Add 2 kg of ethylene glycol montan cerate and 1.5 kg of polydimethylsiloxane diquaternary ammonium salt in sequence, and stir at 50° C. for 20 minutes to obtain an environmentally friendly water treatment flocculation material.

[0034] The performance test results of the prepared environmentally friendly water treatment flocculation materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com