Molybdenum disulfide-cadmium sulfide nanometer composite material and preparing method and application thereof

A technology of nanocomposite materials and molybdenum disulfide, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of increased energy consumption and safety hazards, unfavorable catalytic reactions, and few active sites and other problems, to achieve the effect of low cost, reduced chance of recombination, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

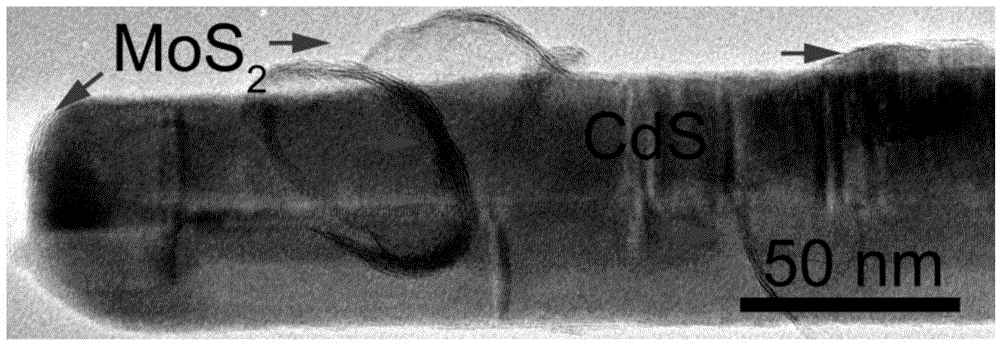

[0039] Dissolve 3.83g of cadmium nitrate and 3.70g of thiourea in 60ml of ethylenediamine, then transfer it to a 100ml polytetrafluoroethylene reactor, seal it and put it in an oven at 160°C for 24 hours. After cooling, it is centrifuged, washed, and vacuum-dried , to obtain cadmium sulfide nanorod powder. The cadmium sulfide nanorods have a length of 0.5-2 μm and a diameter of 20-30 nm.

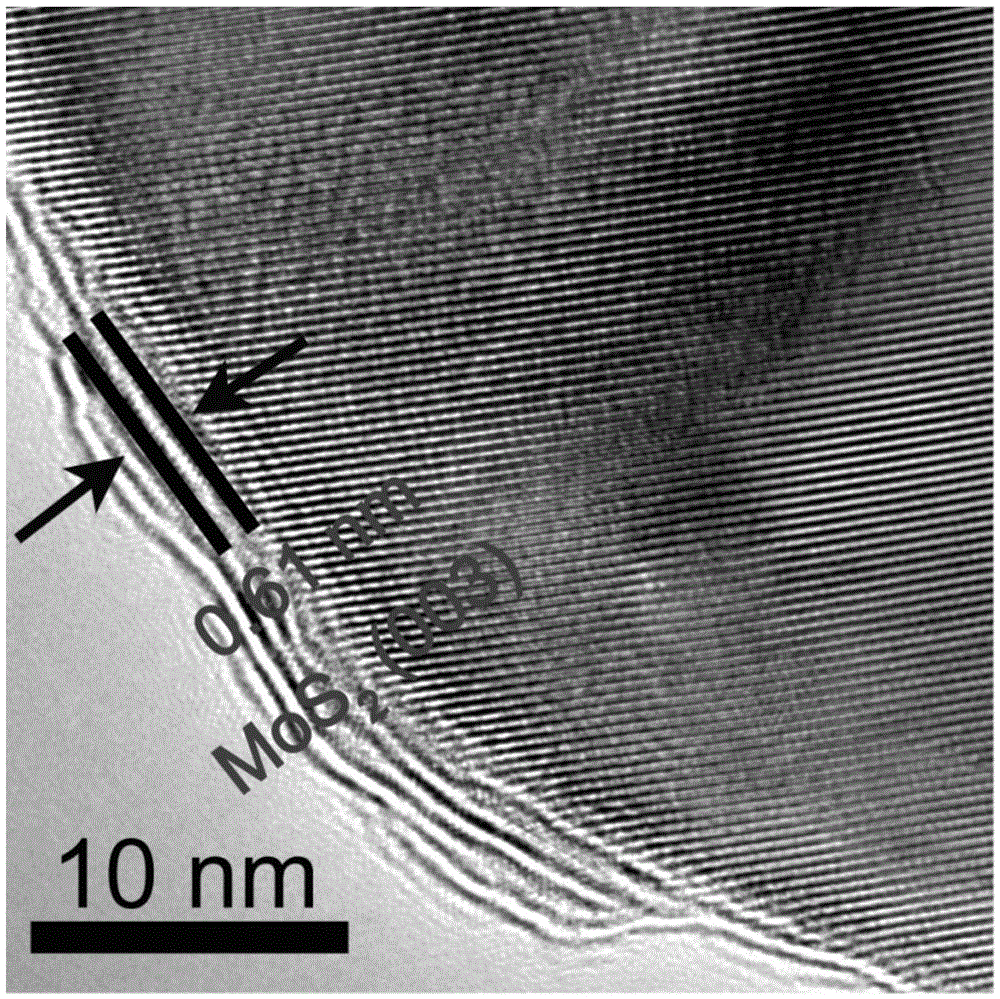

[0040] Weigh 0.50 g of the above-prepared cadmium sulfide nanorod powder, ultrasonically disperse it in 30 ml of deionized water, add 0.08 g of sodium molybdate and 0.12 g of thiourea, and stir vigorously for 0.5 hours; then transfer the suspension into 50 mL of polytetrafluoroethylene In the reaction kettle, seal it and put it in an oven at 220°C for 24 hours to react, after cooling, centrifuge, wash, and vacuum dry to obtain MoS 2 / CdS nanocomposites.

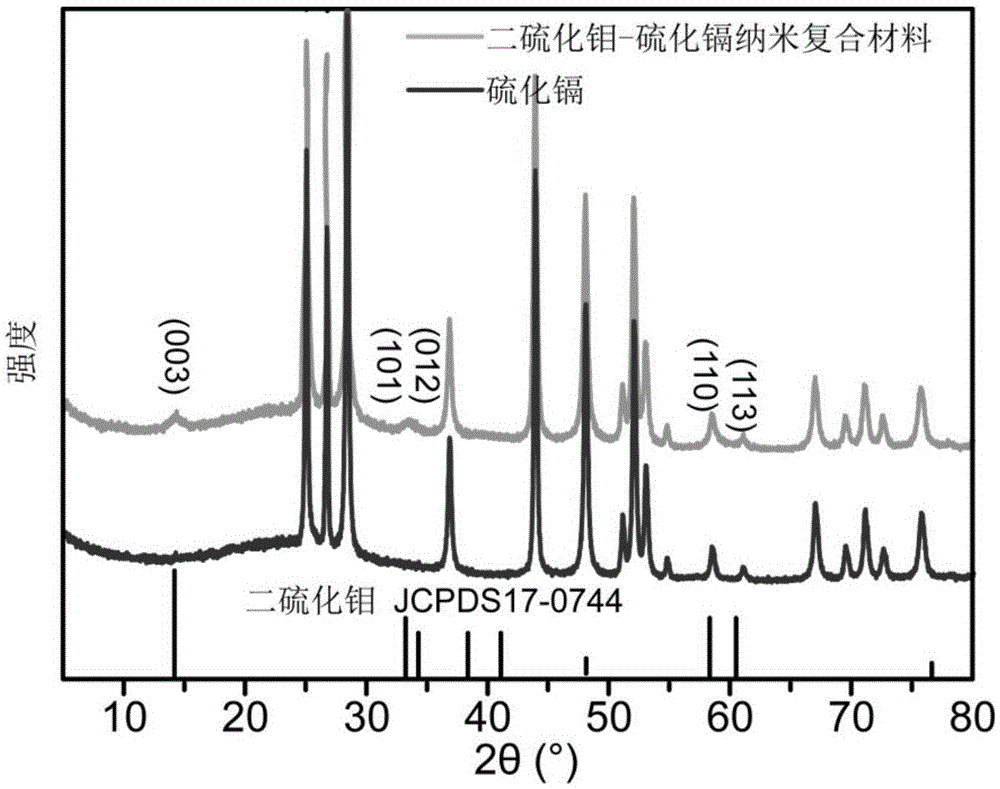

[0041] figure 1 For the MoS prepared in Example 1 2 / CdS nanocomposites as well as pure CdS nanorods and MoS 2 The powder X-ray diffr...

Embodiment 2

[0050] The specific preparation method is basically the same as that in Example 1, except that cadmium chloride is used instead of cadmium nitrate to prepare CdS nanorods, and then MoS 2 / CdS nanocomposites. The MoS prepared in embodiment 2 2 The / CdS nanocomposite material was tested for its photocatalytic hydrogen production performance by the same method as in Example 1, and its photocatalytic water decomposition activity for hydrogen production was 49.18mmol / g / h.

Embodiment 3

[0052] The specific preparation method is basically the same as that in Example 1, except that: the solvothermal reaction is carried out at a temperature of 220° C. for 12 hours to prepare CdS nanorods. According to the same method as in Example 1, the MoS prepared in Example 3 was tested 2 / CdS nanocomposite photocatalytic water splitting hydrogen production performance, its photocatalytic water splitting hydrogen production activity is 49.24mmol / g / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com