Carbon nanotube/silicon carbide foam catalytic composite material and preparation method thereof

A technology of foamed silicon carbide and carbon nanotubes, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the difficulty of separating carbon nanotube coil structures, increase the difficulty of carbon nanotubes, and carbon nanotubes The problem of low density of the pipeline group is achieved by a simple and easy method, which is beneficial to heat conduction and resists pressure drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

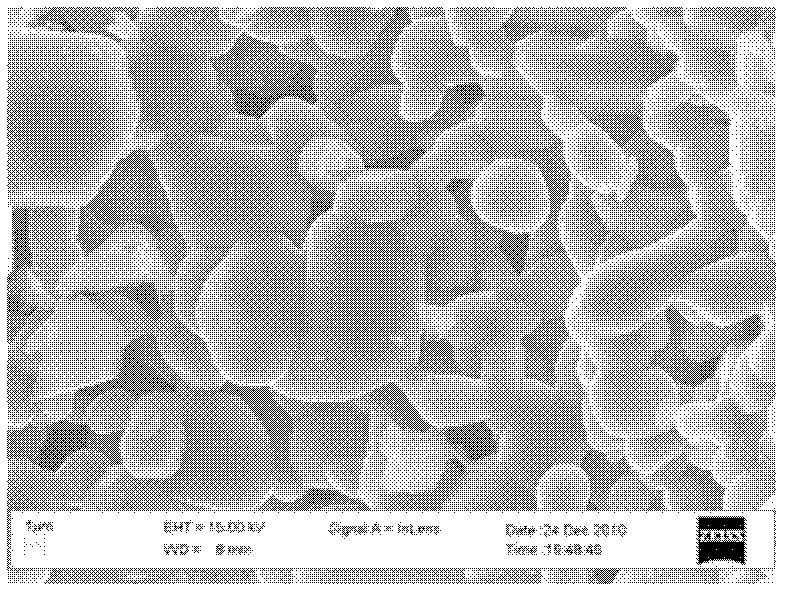

[0034] (1) Foamed silicon carbide pretreatment: (a) Put the foamed silicon carbide into acetone and ethanol solutions successively, and ultrasonically clean each for 20 minutes. (b) Wash the foamed silicon carbide obtained in step (a) in deionized water to remove impurities on the surface of the foamed silicon carbide, dry the sample and collect it for later use. Figure (1) is a scanning electron microscope picture of foamed silicon carbide.

[0035] (2) Catalyst loading on the surface of foamed silicon carbide: Prepare the precursor solution of the composite catalyst according to the catalyst ratio, and mix iron nitrate, magnesium nitrate, aluminum nitrate, urea and deionized water according to the ratio of 0.2g: 0.1g: 2g: 10g and 150ml Proportions were put into a three-necked flask and stirred to form a uniform solution. Put 1 g of foamed silicon carbide in step (1) into the solution in the above-mentioned three-necked flask. Then the three-necked flask was put into an oil...

Embodiment 2

[0042] (1) Foamed silicon carbide pretreatment: (a) Put the foamed silicon carbide into acetone and ethanol solutions successively, and ultrasonically clean each for 40 minutes. (b) Wash the foamed silicon carbide obtained in step (a) in deionized water to remove impurities on the surface of the silicon carbide, dry the sample and collect it for later use.

[0043] (2) Catalyst supported on the surface of foamed silicon carbide: Prepare the precursor solution of the composite catalyst according to the catalyst ratio, put iron nitrate, magnesium nitrate, aluminum nitrate, urea and deionized water according to the ratio of 2g: 6g: 4g: 45g and 250ml into a three-necked flask, and stirred to form a uniform solution. Put 10 g of the foamed silicon carbide in step (1) into the solution of the above-mentioned three-necked flask and soak it. Then the three-necked flask was put into an oil bath, stirred at a rotation speed of 30 rpm, and the temperature was raised to 100° C., and a co...

Embodiment 3

[0046] (1) Foamed silicon carbide pretreatment: (a) Put the foamed silicon carbide into acetone and ethanol solutions successively, and ultrasonically clean each for 60 minutes. (b) Wash the foamed silicon carbide obtained in step (a) in deionized water to remove impurities on the surface of the silicon carbide, dry the sample and collect it for later use.

[0047] (2) Catalyst supported on the surface of foamed silicon carbide: Prepare the precursor solution of the composite catalyst according to the catalyst ratio, put iron nitrate, magnesium nitrate, aluminum nitrate, urea and deionized water in the ratio of 6g: 15g: 12g: 100g and 500ml into a three-necked flask, and stirred to form a uniform solution. Put 20 g of the foamed silicon carbide in step (1) into the solution of the above-mentioned three-neck flask for soaking. Then the three-neck flask was put into an oil bath, stirred at a rotation speed of 50 rpm, and the temperature was raised to 120° C., and a constant temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com