Needle-like strontium carbonate fine powder and method for producing same

A strontium carbonate, acicular technology, applied in the field of acicular strontium carbonate micropowder and its manufacturing, can solve the problems of acicular strontium carbonate particle aggregation and achieve excellent dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

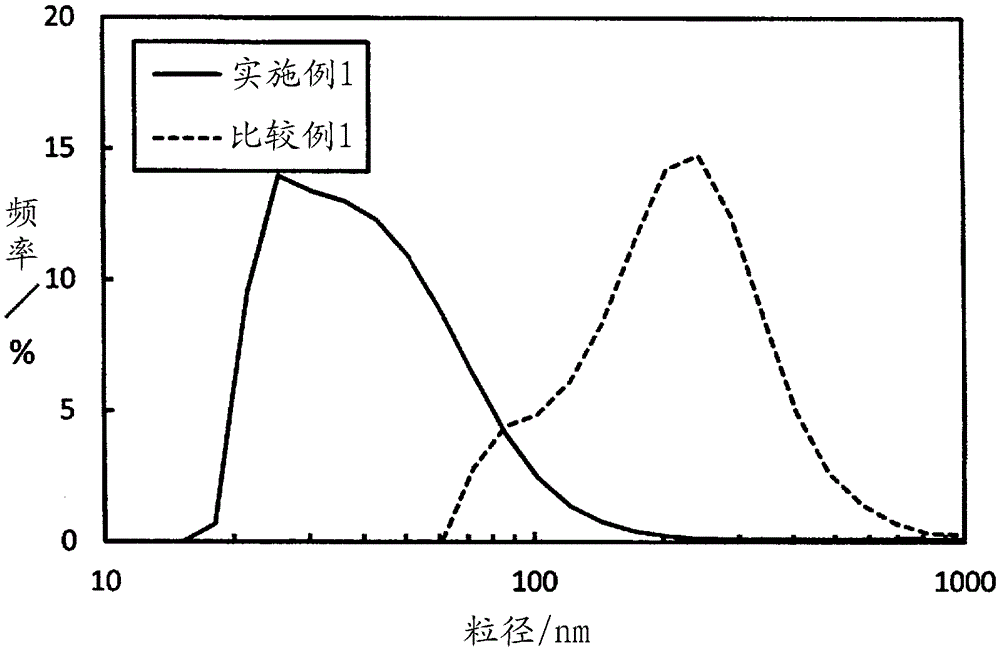

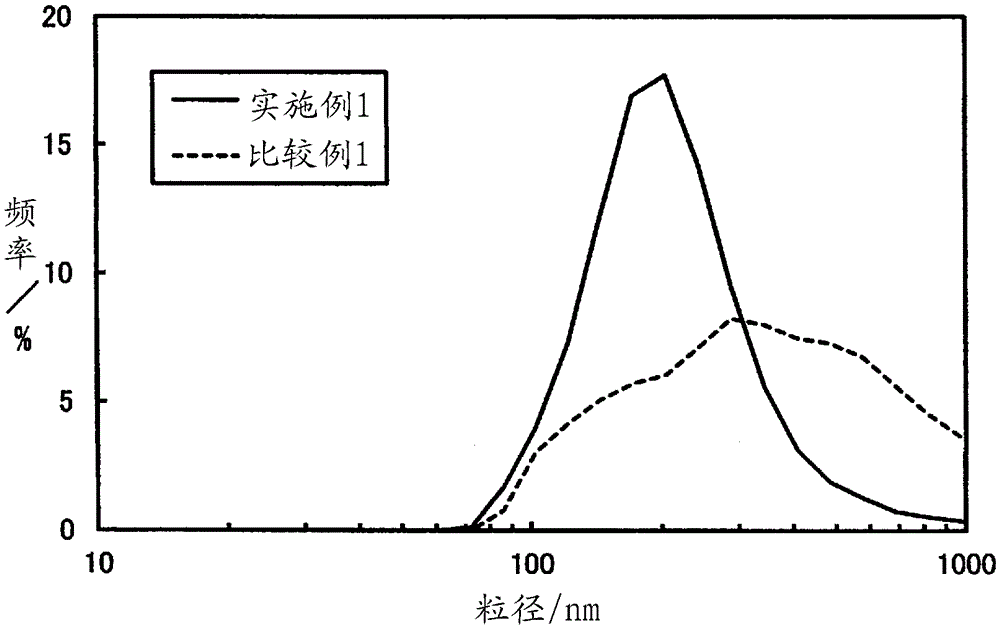

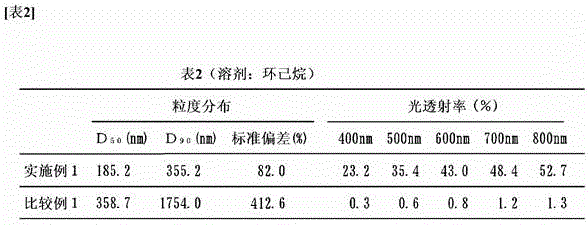

Embodiment 1

[0095] (1) Manufacture of needle-like strontium carbonate particle water-based slurry

[0096] 366 g of strontium hydroxide octahydrate (special grade reagent, purity: 96% or higher) was added to 3 L of pure water at a water temperature of 10° C. and mixed to prepare an aqueous suspension of strontium hydroxide having a concentration of 5.6% by mass. 14.2 g of DL-tartaric acid (special grade reagent, purity: 99% or higher) (0.039 g per 1 g of strontium hydroxide) was added to the strontium hydroxide aqueous suspension, and stirred to dissolve in the aqueous suspension. Next, the temperature of the strontium hydroxide aqueous suspension was maintained at 10° C. while continuing to stir, and a flow rate of 0.5 L / min (2.9 mL / min relative to 1 g of strontium hydroxide) was added to the aqueous suspension. ) to blow carbon dioxide gas until the pH of the aqueous suspension reaches 7 to generate strontium carbonate particles, and then continue stirring for 30 minutes to obtain an aq...

Embodiment 2

[0118] (1) Manufacture of Acicular Strontium Carbonate Micropowder

[0119] (a) Reaction process

[0120] 366 g of strontium hydroxide octahydrate (special grade reagent, purity: 96% or higher) was added to 3 L of pure water at a water temperature of 10° C. and mixed to prepare an aqueous suspension of strontium hydroxide having a concentration of 5.6% by mass. DL-tartaric acid (special grade reagent, purity: 99% or more) was added to the strontium hydroxide aqueous suspension, and stirred to dissolve in the aqueous suspension. Next, while maintaining the temperature of the strontium hydroxide aqueous suspension at 10°C, stirring was continued, and a flow rate of 3.75 L / min (22 mL / min relative to 1 g of strontium hydroxide) was injected into the aqueous suspension. Carbon dioxide gas was blown in until the pH of the aqueous suspension reached 7 to generate needle-shaped strontium carbonate particles. Then, stirring was continued for 30 minutes to prepare an aqueous suspensio...

Embodiment 3

[0130] (1) Manufacture of Acicular Strontium Carbonate Micropowder

[0131] (a) Reaction process? (b) Ripening process

[0132] In the reaction process of Example 2, the flow rate of carbon dioxide gas is set to 0.5L / min (2.9mL / min flow rate relative to 1g of strontium hydroxide), and the needle-shaped strontium carbonate particle aqueous suspension is Except for heat-processing at 95 degreeC for 12 hours, it carried out similarly to Example 2, and produced the aqueous slurry of acicular strontium carbonate particle.

[0133] (c) Surface treatment process

[0134] In the surface treatment process of Example 2, 16.24 g of Mariarim SC-0505K (manufactured by NOF Corporation) was added as Compound A (8 parts by mass relative to 100 parts by mass of strontium carbonate particles), and Compound C (Naimin S- 204) except that the addition amount was 46.69 g (23 parts by mass with respect to 100 parts by mass of strontium carbonate particles), and the surface treatment of the needle-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com