Method for preparing synchrotron-radiation X-ray absorption fine-structure test sample of hydrogen storage material

A technology for absorbing fine structures and hydrogen storage materials, applied in the preparation of test samples, material analysis using radiation diffraction, etc., can solve problems such as easy oxidation, and achieve the effects of avoiding oil leakage, advanced preparation technology, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

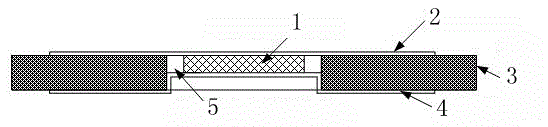

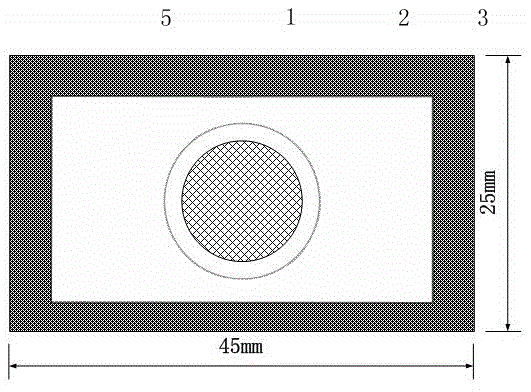

Embodiment 1

[0034] Regulate the argon atmosphere glove box so that the argon pressure in the argon atmosphere glove box is kept at 0.8mbar, and the partial pressures of water and oxygen are both lower than 0.1ppm. In the argon atmosphere glove box, weigh 30mg of LaNi with an electronic balance 5 For the alloy sample, weigh 90mg of LiF powder and pour it into an agate mortar, grind and mix well until the particle size of the sample powder is between 30-38um, and the particle size of the powder is confirmed by SEM. In an argon atmosphere glove box, weigh 40 mg of the ground powder sample with an electronic balance and put it into an HF-12 tableting mold, shake the mold, and then tap the glove box table to ensure that the powder in the mold is basically evenly distributed, and then insert Put up the pressing rod, slowly rotate the pressing rod to spread the sample powder evenly in the mold, put the HF-12 tableting mold on the HY-12 tableting machine, and make the center of the pressing rod al...

Embodiment 2

[0038] Regulate the nitrogen atmosphere glove box so that the argon pressure in the nitrogen atmosphere glove box is kept at 1mbar, and the partial pressures of water and oxygen are both lower than 0.1ppm. In the nitrogen atmosphere glove box, weigh 33mg of LaNi with an electronic balance 4.25 Al 0.75 For the alloy sample, weigh 90mg of BN powder and pour it into an agate mortar, grind and mix well until the particle size of the sample powder is between 30-38um, and the particle size of the powder is confirmed by SEM. In the process, 41 mg of the ground powder sample was weighed by an electronic balance and put into the HF-12 tableting mold, the mold was shaken, and then the table of the glove box was tapped to ensure that the powder in the mold was basically evenly distributed, and then the pressing rod was inserted, slowly Slowly rotate the pressure rod to spread the sample powder evenly in the mold, put the HF-12 tablet mold on the HY-12 tablet press, make the center of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com