Recombinant bacterium providing improved efficiency in convertive production of Alpha-phenylpyruvic acid

A technology of phenylpyruvate and recombinant bacteria, applied in the field of recombinant bacteria, can solve the problems of low efficiency, low selectivity, toxicity of co-substrates, etc., achieve high yield, improve transformation efficiency, and improve regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

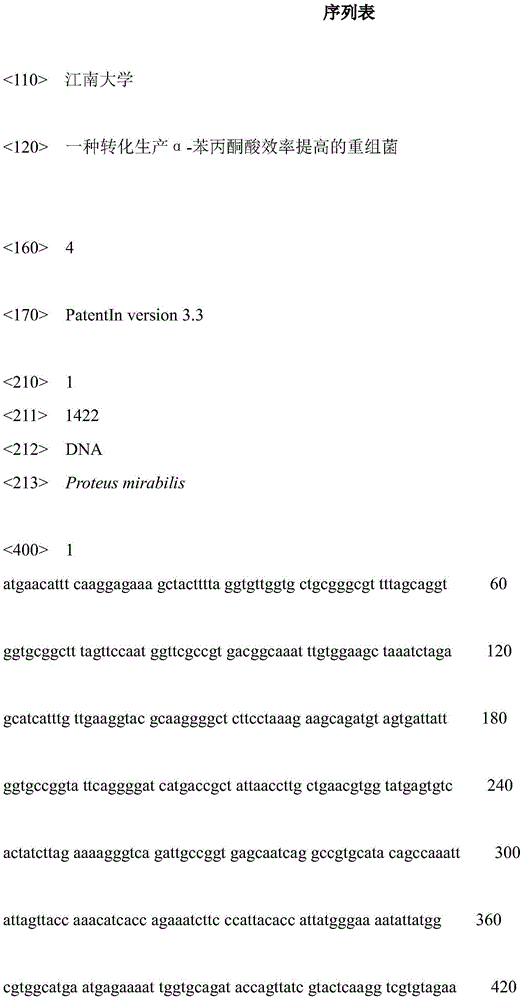

[0025] Cloning of embodiment 1 rebH and aad gene and construction of recombinant whole cell catalyst

[0026] The aad gene was synthesized, the nucleotide sequence of which is shown in SEQ ID NO.1, and further digested with BamHI and HindIII, and then cloned into the multi-cloning 1 site of the plasmid pRSFDuet-1 to construct the recombinant plasmid pRSFDuet-AAD. Using the Lechevalieria aerocolonigenes genome as a template and using rebH-MCS2-S and rebH-MCS2-A as primers, the rebH gene was amplified by PCR, and its nucleotide sequence is shown in SEQ ID NO.2. The PCR product was double digested with NdeI and XhoI, and then cloned into the multi-cloning 2 site of the plasmid pRSFDuet-AAD to construct the plasmid pRSFDuet-AAD-RebH. The recombinant plasmids pRSFDuet-AAD and pRSFDuet-AAD-RebH were transformed into Escherichia coli BL21(DE3), and BL21(pRSFDuet-AAD) and BL21(pRSFDuet-AAD-RebH) were constructed.

Embodiment 2

[0027] Preparation of embodiment 2 whole cell catalyst and whole cell transformation process

[0028] The recombinant Escherichia coli in Example 1 after co-expressing L-amino acid deaminase and halogenase was inoculated into seed medium (containing 10 mg / L kanapenicillin), and cultivated overnight at 37° C. and 200 rpm. Fermentation was carried out in a 500mL Erlenmeyer flask, 1% inoculum was added to 50mL fermentation medium, cultured at 37v, when OD 600 When it reaches 0.6-0.8, add 0.4mMIPTG to induce the expression of L-amino acid deaminase and halogenase. After induction at 28°C for 24h, centrifuge at 8,000rpm for 10-15min at low temperature, collect the bacteria, and wash with 20mM Tris-HCl (pH8.0) buffer Get the bacteria twice.

[0029] The whole cell transformation system is: L-phenylalanine 20-30g / L, whole cell catalyst 4-6g / L, L-tryptophan 1-2g / L, in 0.9% NaCl at pH 8.0, in 36-37°C, 200-220rpm transformation for 6-10h. The PPA yields of BL21(pRSFDuet-AAD) and BL21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com