High-strength, solvent-free and environment-friendly impregnating varnish and preparation method thereof

A solvent-free, high-strength technology, used in epoxy resin coatings, coatings, etc., can solve the problems of high shrinkage of unsaturated polyester, low glass transition temperature, hard and brittle epoxy resin, etc. Low volatility, fast curing speed, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

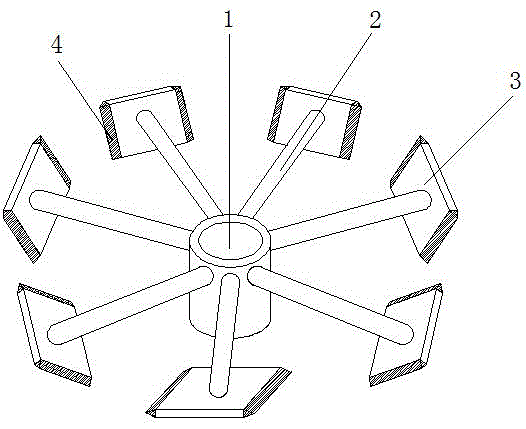

Image

Examples

Embodiment

[0021] Example: A high-strength solvent-free environment-friendly impregnating paint, the impregnating resin comprises the following components in parts by weight: 20-25 parts of epoxy resin, 20-25 parts of liquid anhydride, 30 parts of low-viscosity epoxy reactive diluent, curing agent 5 parts, accelerator 1-3 parts, initiator 1.5-3 parts, defoamer 2-3 parts.

[0022] Preferably, the accelerator is p-toluenesulfonic acid.

[0023] Preferably, the initiator is dicumyl peroxide.

[0024] A method for high-strength solvent-free environment-friendly dipping paint, comprising the following steps:

[0025] S1: Put the curing agent into the reaction kettle according to the parts by weight, then turn on the oblique agitator, and preheat the reaction kettle. Gradually add liquid anhydride for pre-polymerization, the reaction time is 1-2 hours;

[0026] S2: Stir and mix the initiator and the accelerator according to parts by weight to form an adjusted mixed solution;

[0027] S3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com