Siloxane-modified phenolic resin for hot melt preimpregnation technology and preparation method of siloxane-modified phenolic resin for hot melt preimpregnation technology

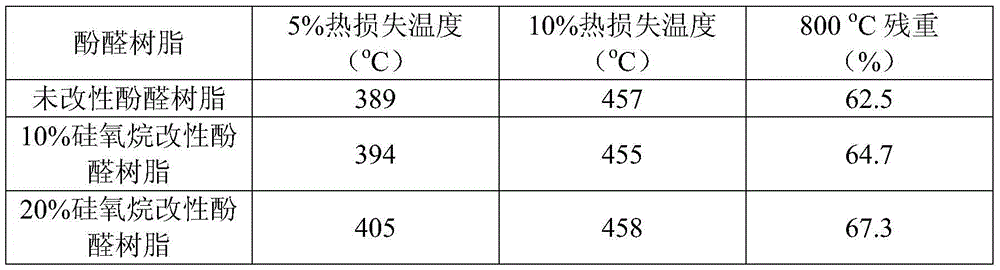

A technology of siloxane modification and phenolic resin, which is applied in the field of siloxane-modified phenolic resin for hot-melt prepreg process and its preparation, can solve the problems of not taking into account the improvement of the manufacturability of phenolic resin-based composite materials, and achieve Excellent thermal properties, high heat resistance, and low volatile matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of siloxane-modified phenolic resin for hot-melt prepreg process of the present invention comprises the following steps:

[0030] (1) In terms of parts by mass, take 100 parts of barium phenolic resin in a three-neck reaction flask, add 5 parts of polyester polyurethane while stirring at room temperature, and stir to obtain a mixture, which is stored in refrigeration for later use.

[0031] (2) Add 10 parts of vinyltrimethoxysilane, 1 part of water, 2 parts of ethanol, and 1 part of hydrochloric acid into a beaker in turn, stir magnetically at room temperature, and stir evenly to obtain a siloxane intermediate for use.

[0032](3) After taking out the mixture and adding it to the three-necked reaction flask, stir at a constant speed, take the prepared siloxane intermediate and add it to the mixture drop by drop at 35°C, with an average of 2 seconds / drop. After the drop is completed, the reaction system Stir and react under vacuum for 50 minutes at...

Embodiment 2

[0034] The preparation method of siloxane-modified phenolic resin for hot-melt prepreg technique of the present invention comprises the following steps:

[0035] (1) In terms of parts by mass, take 90 parts of molybdenum phenolic resin in a three-necked reaction flask, add 3 parts of polyester polyurethane while stirring at room temperature, and stir evenly to obtain a mixture, which is refrigerated and placed for use.

[0036] (2) Take 8 parts of γ-glycidyl etheroxypropyltrimethoxysilane, 1 part of water, 1 part of ethanol, and 1 part of phosphoric acid into the beaker in turn, stir magnetically at room temperature, and obtain the siloxane intermediate after stirring evenly. stand-by.

[0037] (3) Take out the mixture and add it to the three-necked reaction flask, stir at a constant speed, take the prepared siloxane intermediate and add it to the mixture drop by drop at 40°C, with an average of 2 seconds / drop. After the drop is completed, the reaction system Stir and react i...

Embodiment 3

[0039] The preparation method of siloxane-modified phenolic resin for hot-melt prepreg process of the present invention comprises the following steps:

[0040] (1) According to the number of parts by mass, take 90 parts of molybdenum phenolic resin in a three-necked reaction flask, add 2 parts of amine-terminated liquid nitrile rubber and 1 part of polyethersulfone while stirring at room temperature, and stir evenly to obtain the mixture. Set aside.

[0041] (2) Add 8 parts of vinyltrimethoxysilane, 1 part of water, 1 part of ethanol, and 1 part of acetic acid into a beaker in turn, stir magnetically at room temperature, and stir evenly to obtain a siloxane intermediate for use.

[0042] (3) Take out the mixture and add it to the three-necked reaction flask, stir at a constant speed, take the prepared siloxane intermediate and add it to the mixture drop by drop at 40°C, with an average of 2 seconds / drop. After the drop is completed, the reaction system Stir and react under va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com