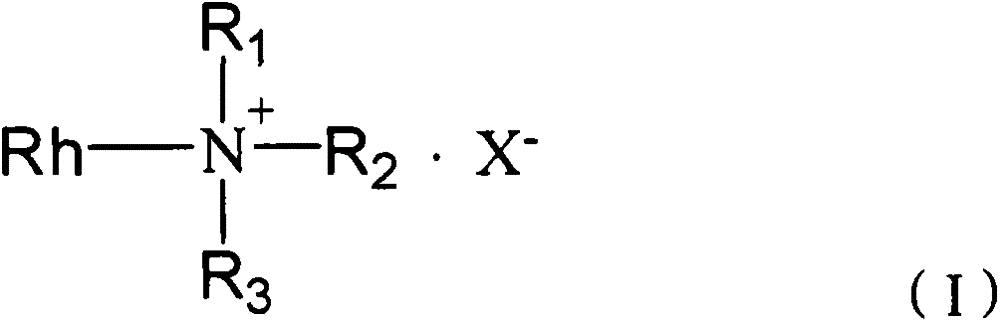

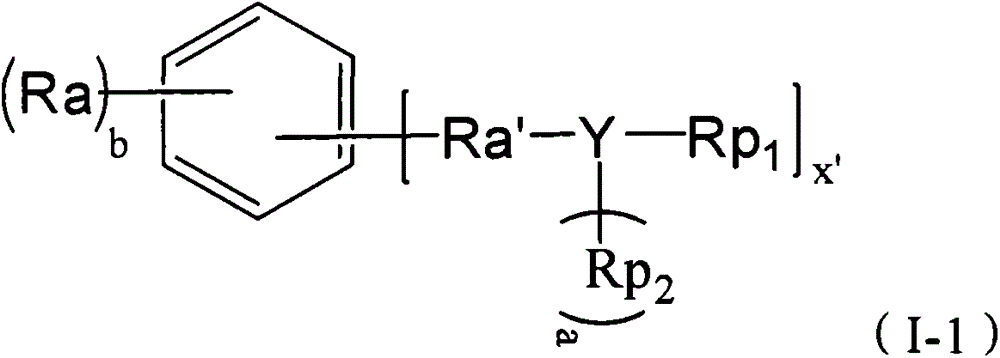

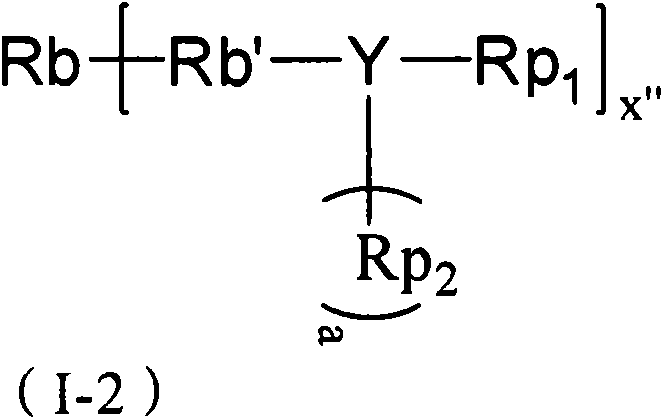

Anionic-cationic-nonionic surfactant, preparation method therefor and application of anionic-cationic-nonionic surfactant

A surfactant, non-ionic technology, applied in the field of anionic-cationic-nonionic surfactants, can solve the problems of low oil displacement efficiency of displacement fluid, reduction of polymer viscosity, difficulty in demulsification of produced fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0312] 20 moles of dodecylaniline and 2 moles of methyl chloride were added into the reactor and the temperature was raised to 80° C. for 5 hours of reaction, and then the (4-dodecylphenyl)methylamine was purified by chromatography. Add 1 mole of (4-dodecylphenyl)methylamine and 0.1 mole of potassium hydroxide into the reaction kettle and raise the temperature to 80°C, reduce the pressure to a vacuum of 0.9, stir for 30 minutes to remove volatile components, and replace with nitrogen The gas in the reactor is 4 times, and the pressure in the reactor is adjusted to 0.2MPa. The temperature of the reaction system was raised to 220° C., and 1 mole of propylene oxide was added into the reaction kettle with nitrogen at a pressure of 0.8 MPa, and the etherified product was obtained after 5 hours of reaction. Dissolve all the etherification products in absolute ethanol to prepare a 40% solution and add it to the reaction kettle, add 1.1 moles of quaternizing agent methyl chloride with...

Embodiment 2

[0314] 20 moles of 4-nonylaniline and 2 moles of methyl chloride were added into the reaction kettle and the temperature was raised to 80°C for 5 hours of reaction, and then (4-nonylphenyl)methylamine was purified by chromatography. Add 1 mole of (4-nonylphenyl)methylamine and 0.1 mole of potassium hydroxide to the reactor and raise the temperature to 80°C, reduce the pressure to a vacuum of 0.9, stir for 30 minutes to remove volatile components, and replace the reactor with nitrogen Inner gas 4 times, adjust the pressure in the reactor to 0.2MPa. The temperature of the reaction system was raised to 220° C., and 1 mole of ethylene oxide was added into the reaction kettle with nitrogen at a pressure of 0.8 MPa, and the etherification product was obtained after 5 hours of reaction. All the etherification products were dissolved in absolute ethanol to prepare a 40% solution and added to the reaction kettle, and 1.1 moles of quaternizing agent methyl chloride were added with nitro...

Embodiment 3

[0316] 20 moles of 9-octadecenylamine and 2 moles of allyl chloride were added into the reaction kettle and the temperature was raised to 80°C for 5 hours of reaction, and then the (9-octadecenyl)allylamine was purified by chromatography. Add 1 mole of (9-octadecenyl) allylamine and 0.1 mole of potassium hydroxide into the reaction kettle, heat up to 80°C and reduce the pressure to a vacuum of 0.9, stir for 30 minutes to remove volatile components, and replace the reaction with nitrogen The gas in the kettle is 4 times, and the pressure in the reactor is adjusted to 0.2MPa. Raise the temperature of the reaction system to 220°C, add 49 moles of propylene oxide into the reactor with nitrogen at a pressure of 0.8 MPa, and add 37 moles of ethylene oxide into the reactor with nitrogen at a pressure of 0.8 MPa after 5 hours of reaction. After 5 hours the etherified product was obtained. All the etherified products were dissolved in absolute ethanol to prepare a 40% solution and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com