Amorphous state ferriferrous oxide/graphene aerogel composite material and preparation method and application thereof

A technology of graphene airgel and ferroferric oxide, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of large volume change, low conductivity, and limited application, and achieve reduced impedance, stable rate performance, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

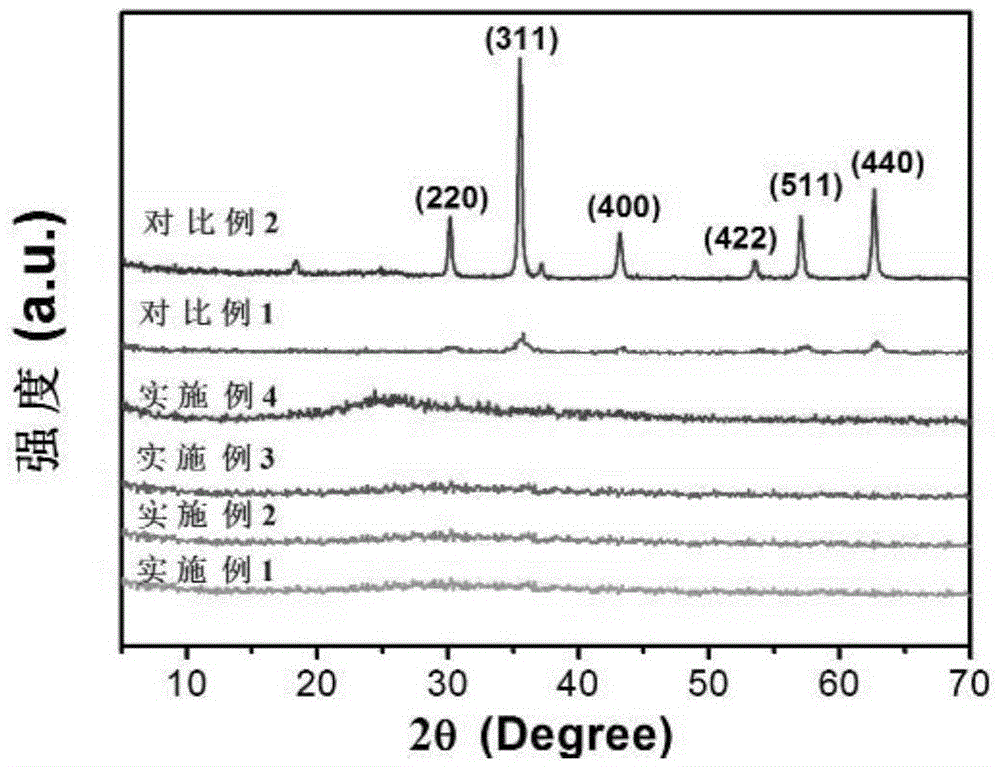

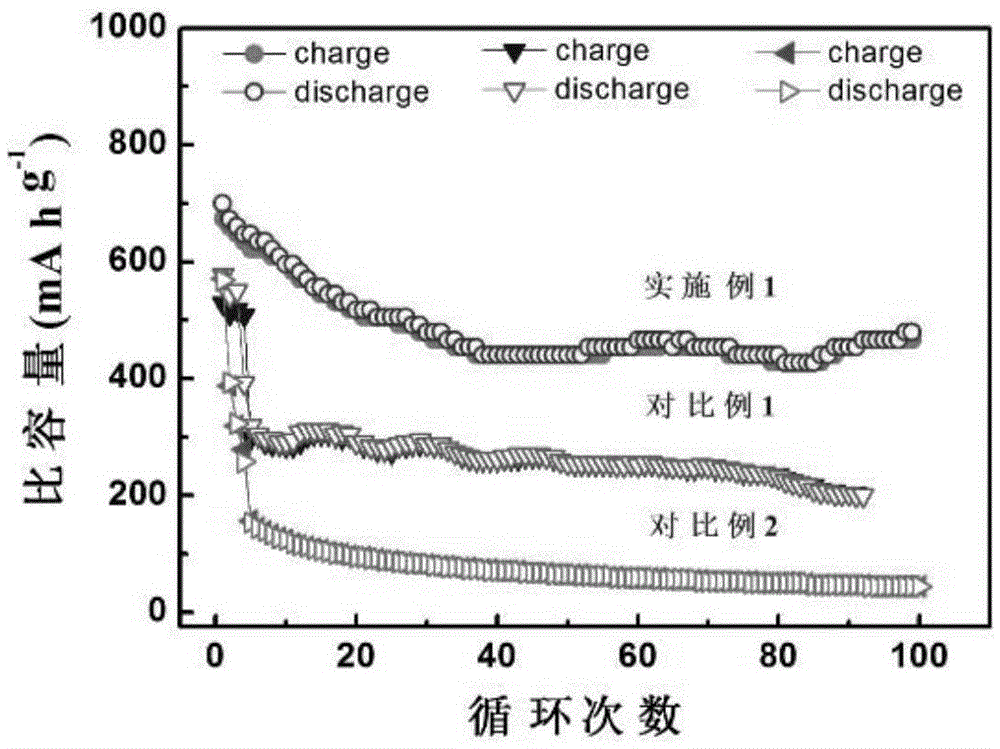

Embodiment 1

[0026] Step 1. Take 30 mL of graphene oxide dispersion, containing about 120 mg of graphene oxide, stir and sonicate for 20 minutes to obtain a uniform suspension;

[0027] Step 2. Add 0.25 g (1.3 mmol) of ferrous chloride tetrahydrate and 0.5 g of sodium ascorbate to the suspension obtained in step 1, and stir for 10 min;

[0028] In step 3, the mixed solution obtained in step 2 was left to stand at 50° C. for 4 hours to form a reduced graphene hydrogel.

[0029] Step 4, transfer the hydrogel obtained in step 3 (remove the excess liquid other than the hydrogel) to 200mL30wt% ammonia water, and leave it for 1h to obtain the amorphous iron ferric oxide / graphene hydrogel composite material. The material is freeze-dried to obtain the amorphous Fe3O4 / graphene airgel composite material.

Embodiment 2

[0031] Step 1. Take 30 mL of graphene oxide dispersion, containing about 120 mg of graphene oxide, stir and sonicate for 20 minutes to obtain a uniform suspension;

[0032] Step 2. Add 0.5 g of ferrous chloride tetrahydrate and 1 g of sodium ascorbate to the suspension obtained in step 1, and stir for 10 min;

[0033] In step 3, the mixed solution obtained in step 2 is allowed to stand at 50° C. for 10 h to form a reduced graphene hydrogel.

[0034] Step 4, transfer the hydrogel obtained in step 3 (remove the excess liquid other than the hydrogel) to 200mL30wt% ammonia water, and leave it for 2h to obtain the amorphous iron ferric oxide / graphene hydrogel composite material. The material is freeze-dried to obtain the amorphous Fe3O4 / graphene airgel composite material.

Embodiment 3

[0036] Step 1. Take 30 mL of graphene oxide dispersion, containing about 120 mg of graphene oxide, stir and sonicate for 20 minutes to obtain a uniform suspension;

[0037] Step 2. Add 1 g of ferrous chloride tetrahydrate and 1.5 g of sodium ascorbate to the suspension obtained in step 1, and stir for 10 min;

[0038] In step 3, the mixed solution obtained in step 2 was left to stand at 50° C. for 8 hours to form a reduced graphene hydrogel.

[0039] Step 4. Transfer the hydrogel obtained in step 3 (remove the excess liquid other than the hydrogel) to 200mL NaOH solution (0.4g / mL), and let it stand for 2h to obtain the amorphous ferric oxide / graphene hydrogel Glue composite material, the material is freeze-dried to obtain the amorphous iron ferric oxide / graphene airgel composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com