Grain structure uniformity evaluation method for nickel-based high-temperature alloy forging

A nickel-based high-temperature alloy with a uniform structure, which is used in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiment of the GH4169 turbine disc as a nickel-base superalloy forging. According to the evaluation method of grain structure uniformity of nickel-based superalloy forgings obtained above, the uniformity of turbine disk forgings obtained by different turbine disk production processes is evaluated, and a relatively good processing technology is selected.

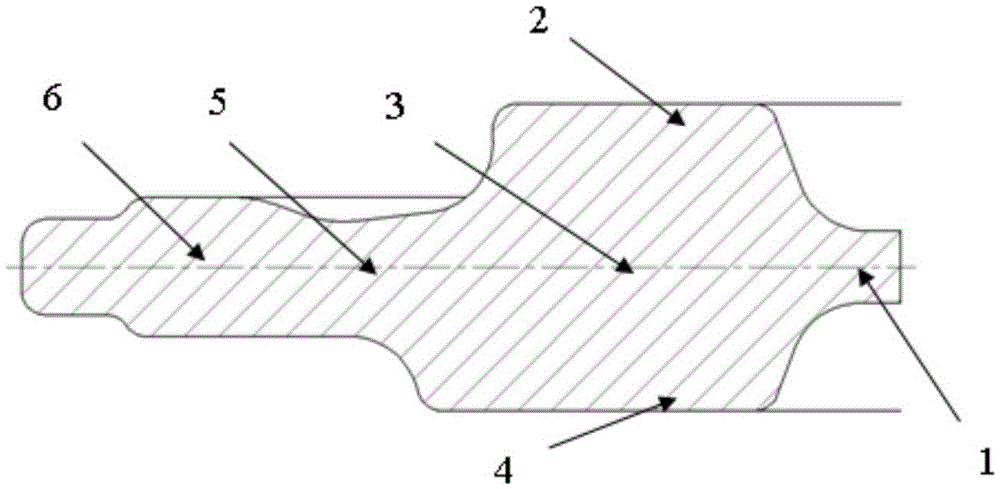

[0057] Turbine disk forging sketch figure 1 As shown, the turbine disk forging is cut along the axial direction, and a quarter of its section is taken. The turbine disk forging is composed of the wheel core 1, the upper end surface of the hub 2, the core part of the hub 3, the lower end surface of the hub 4, the spoke plate 5 and the rim 6 consists of six parts. The distribution diagram of the nodes taken in each part is as follows: Figure 14 shown. Count the grain size grades of different grains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com