Milling and grinding equipment for railway rail profile

A rail milling and grinding technology, which is applied in the field of complete machine layout of rail railway profile milling and refurbishment equipment, can solve the problems of large vertical component force, short knife grain life, low operating efficiency, etc., and achieve the elimination of instantaneous impact, knife The effect of stable disk operation and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

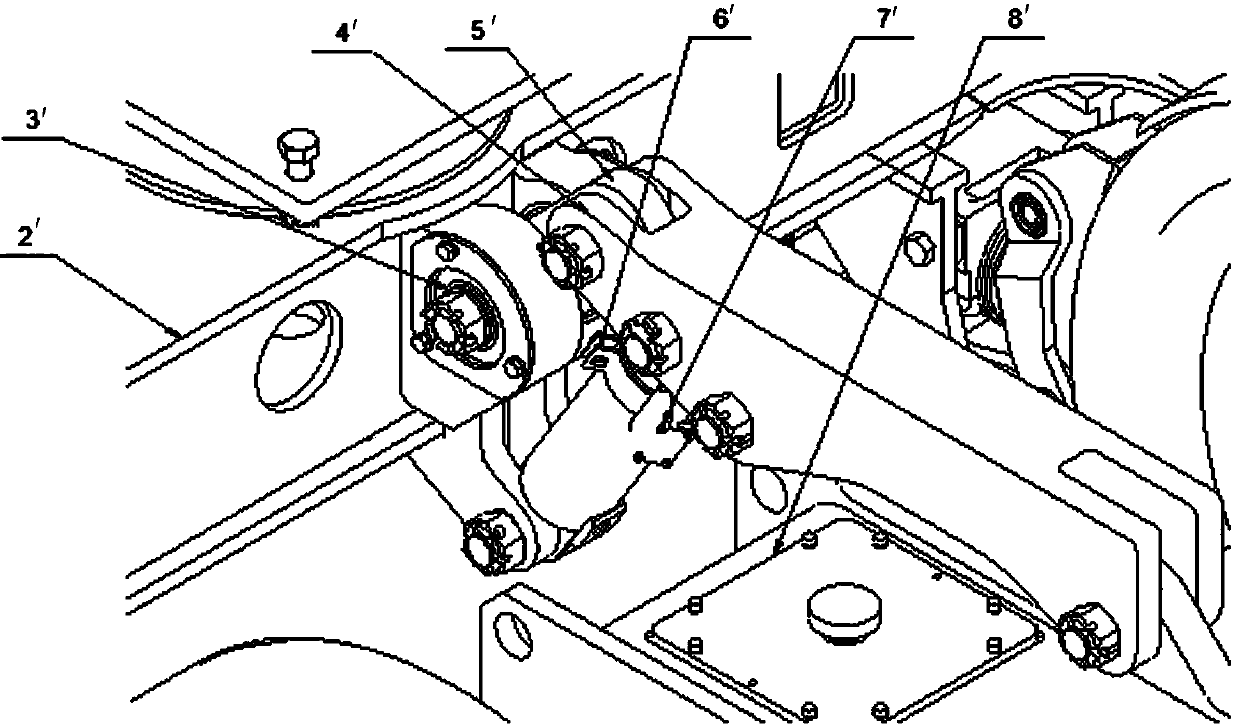

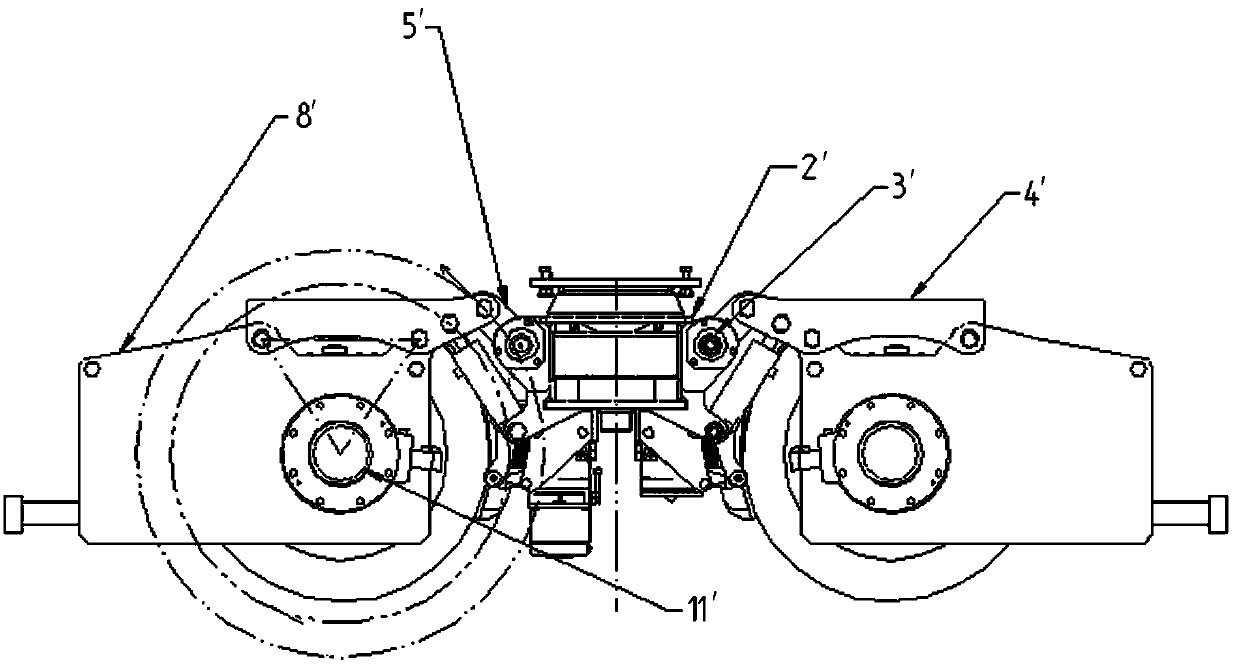

[0075] Embodiment 1.1: A railway rail profile milling and grinding equipment, which includes two cars. The car in front of the working direction is defined as the front car, and the car behind the working direction is defined as the rear car. According to the basic operation sequence of the milling and grinding equipment , between the front operation bogie 10 and the rear operation bogie 13 at the lower part of the equipment frame 12 of the front vehicle A, a milling device 7, a milling function room 6, and an air compressor 5 for collecting scraps of the milling device are arranged from front to rear; On the top of the equipment rack 12 of the front car A, the order from front to back is the operator's cab 9, which has the function of high-speed operation, the milling device hydraulic pump station room 8, and the milling device iron filings collection air compressor room 4 , milling device electrical room 3, iron filings collecting screw conveyor 2, iron filings air compressed...

Embodiment 12

[0083] Embodiment 1.2: A railway rail profile milling and grinding equipment, the same as Embodiment 1.1, except that the diameter of the milling disk is 1000 mm.

Embodiment 13

[0084] Embodiment 1.3: A railway rail profile milling and grinding equipment, the same as Embodiment 1.1, except that the diameter of the milling disk is 1200 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com