Barium sulfate/polyvinyl alcohol composite fiber and preparation method thereof and non-woven fabric

A polyvinyl alcohol and composite fiber technology, which is used in the manufacture of non-woven fabrics, single-component synthetic polymer rayon, and rayon, can solve problems such as poor mechanical properties and radiation resistance, and achieve smooth hand feel and production. Safe and reliable process, soft glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

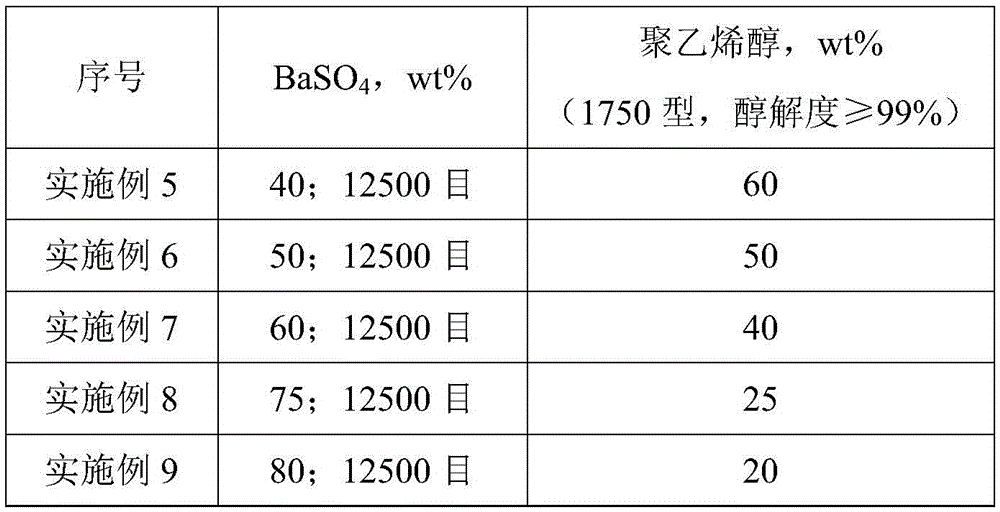

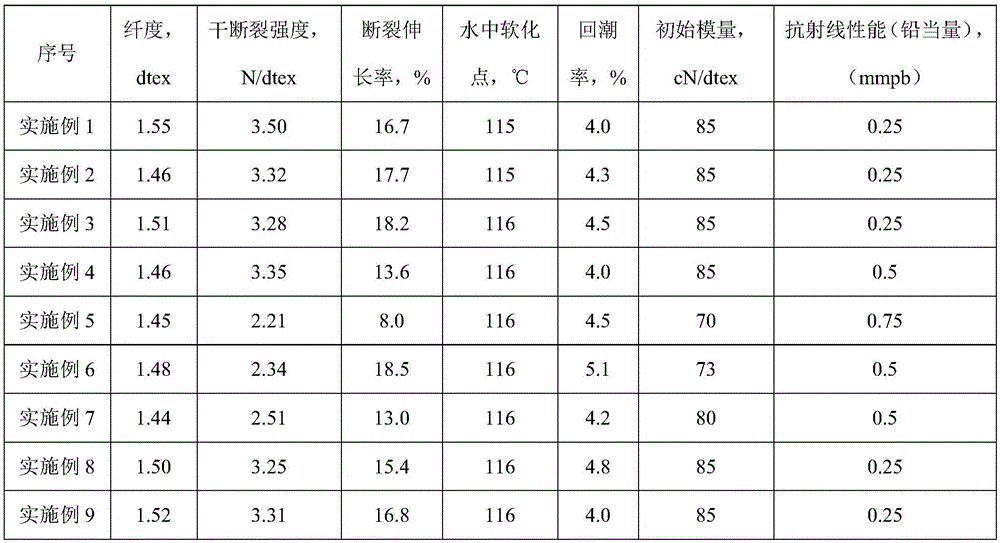

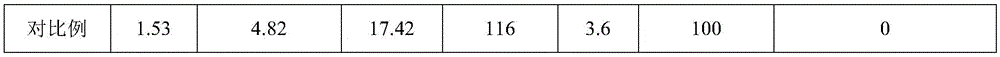

Examples

Embodiment 1

[0022] The barium sulfate / polyvinyl alcohol composite fiber of this embodiment is composed of the following components in mass percentage: 20% of barium sulfate and 80% of polyvinyl alcohol. The degree of polymerization of polyvinyl alcohol is 1750±50, the degree of alcoholysis ≥ 99%, and the particle size of barium sulfate is 6000 mesh.

[0023] The preparation method of the barium sulfate / polyvinyl alcohol composite fiber of the present embodiment may further comprise the steps:

[0024] 1) Add polyvinyl alcohol to 50°C water and raise the temperature to 95°C, stir until completely dissolved to obtain a polyvinyl alcohol solution; add barium sulfate powder, stir and mix thoroughly for 2 hours, adjust the pH value of the system to 8, and the system temperature to 95°C , after filtering and standing for degassing for 6h, the mass concentration (BaSO 4 and polyvinyl alcohol mass concentration) is 10% spinning stock solution;

[0025] 2) The spinning dope is subjected to wet s...

Embodiment 2

[0028] The barium sulfate / polyvinyl alcohol composite fiber of this embodiment is composed of the following components in mass percentage: 25% of barium sulfate and 75% of polyvinyl alcohol. The degree of polymerization of polyvinyl alcohol is 1750±50, the degree of alcoholysis ≥ 99%, and the particle size of barium sulfate is 8000 mesh.

[0029] The preparation method of the barium sulfate / polyvinyl alcohol composite fiber of the present embodiment may further comprise the steps:

[0030] 1) Add polyvinyl alcohol to 50°C water and raise the temperature to 95°C, stir until completely dissolved to obtain a polyvinyl alcohol solution; add barium sulfate powder, stir and mix thoroughly for 2 hours, adjust the pH value of the system to 6, and the system temperature to 95°C , after filtering and standing for degassing for 6h, the mass concentration (BaSO 4 and polyvinyl alcohol mass concentration) is 16% spinning dope;

[0031] 2) The spinning stock solution is subjected to wet s...

Embodiment 3

[0034] The barium sulfate / polyvinyl alcohol composite fiber of this embodiment is composed of the following components in mass percentage: 30% of barium sulfate and 70% of polyvinyl alcohol. The degree of polymerization of polyvinyl alcohol is 1750±50, the degree of alcoholysis ≥ 99%, and the particle diameter of barium sulfate is 10000 mesh.

[0035] The preparation method of the barium sulfate / polyvinyl alcohol composite fiber of the present embodiment may further comprise the steps:

[0036] 1) Add polyvinyl alcohol to 50°C water and raise the temperature to 100°C, stir until completely dissolved to obtain a polyvinyl alcohol solution; add barium sulfate powder, stir and mix thoroughly for 2 hours, adjust the pH value of the system to 10, and the system temperature to 100°C , after filtering and standing for degassing for 6h, the mass concentration (BaSO 4 and polyvinyl alcohol mass concentration) is 20% spinning stock solution;

[0037] 2) The spinning stock solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com