Environment-friendly nanometer emulsion fracturing fluid and preparation method thereof

An environmentally friendly, nanoemulsion technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of water system and environmental pollution, difficult molecular weight control, low solid content of aqueous solution, etc., and achieve low reservoir damage. , Excellent effect of reducing surface activity and good sand suspension ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

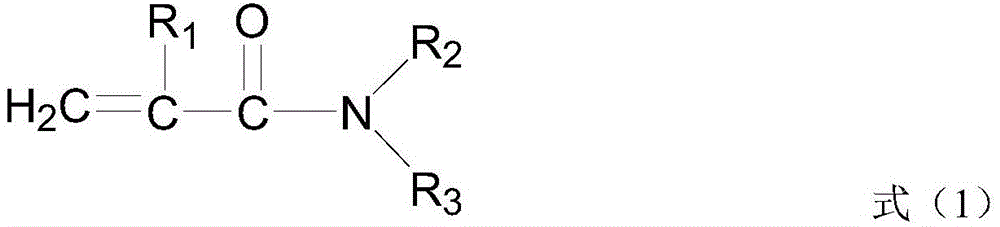

[0040] This embodiment provides a method for preparing an environmentally friendly nanoemulsion fracturing fluid, comprising the following steps:

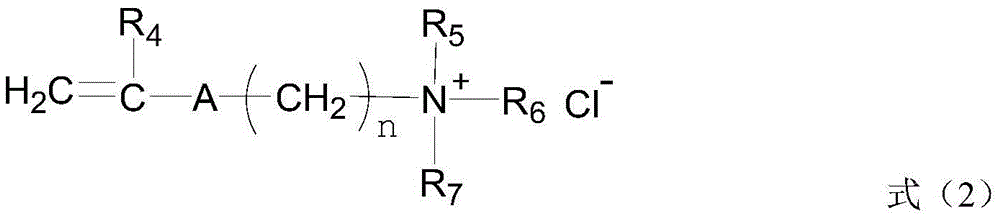

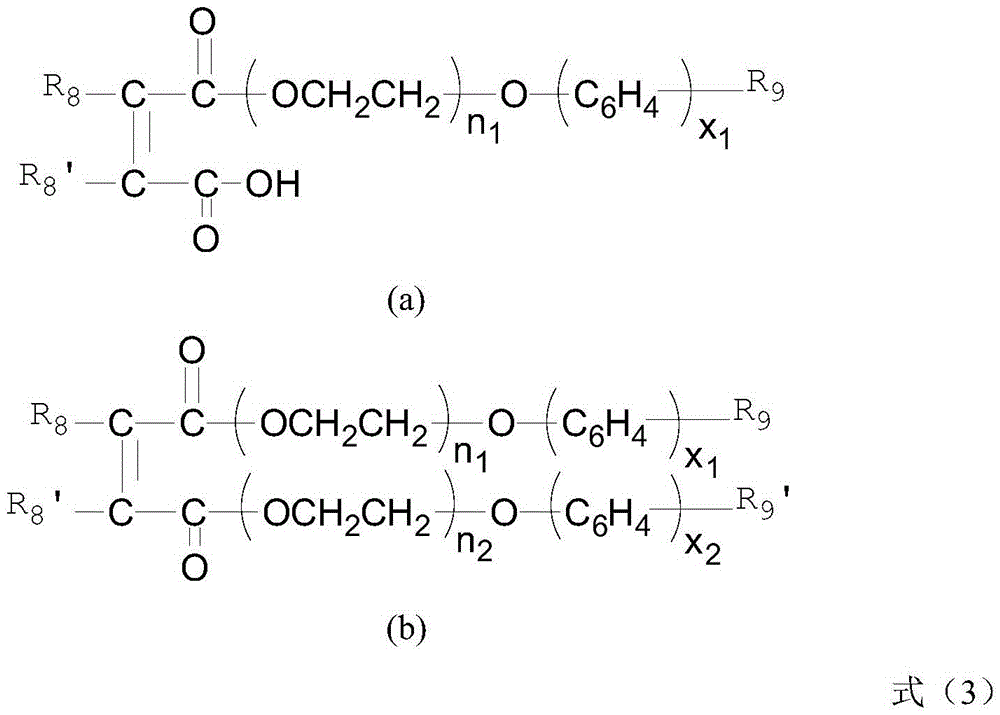

[0041](1) 15 parts by weight of acrylamide, 1 part by weight of methacryloxyethyltrimethylammonium chloride, 2 parts by weight of octylphenol polyoxyethylene ether (OP-10) maleic acid monoester , 20 parts by weight of ammonium sulfate, 3 parts by weight of polymethacryloyloxyethyltrimethylammonium chloride are added to the reactor and mixed with 70 parts by weight of deionized water to form a mixed solution, and the mixed solution is adjusted The pH value is 6.5;

[0042] (2) Introduce nitrogen gas into the mixed liquid to remove oxygen, and raise the temperature of the mixed liquid to 55° C., under the protection of nitrogen, add 0.5 parts by weight of azobisisobutyronitrile to react for 5 hours, and use high-speed dispersion with a rotation speed of 15000 rpm. The operation time is 3 minutes; the pressure of high-pressure homoge...

Embodiment 2

[0047] This embodiment provides a method for preparing an environmentally friendly nanoemulsion fracturing fluid, comprising the following steps:

[0048] (1) 20 parts by weight of acrylamide, 3 parts by weight of diallyl dimethyl ammonium chloride, 2 parts by weight of nonylphenol polyoxyethylene ether (NP-10) diester of maleate, 25 parts by weight of Parts of magnesium sulfate and 5 parts by weight of polyacryloyloxyethyltrimethylammonium chloride are added to the reactor and mixed with 80 parts by weight of deionized water to form a mixed solution, and the pH value of the mixed solution is adjusted to 7.2;

[0049] (2) Introduce nitrogen gas into the mixed solution to remove oxygen, and raise the temperature of the mixed solution to 60°C. Under the protection of nitrogen, add 1 part by weight of azobisisobutylamidine hydrochloride to react for 6 hours, and use high-speed dispersion to The rotation speed is 10000rpm, and the operation time is 5min; the pressure of high-press...

Embodiment 3

[0054] This embodiment provides a method for preparing an environmentally friendly nanoemulsion fracturing fluid, comprising the following steps:

[0055] (1) 2-methacrylamide of 25 parts by weight, trimethylallyl ammonium chloride of 5 parts by weight, fatty alcohol polyoxyethylene ether (Pingping plus O-20) maleic acid monosodium ether of 2 parts by weight The potassium sulfate of ester, 25 parts by weight, the polydiallyl dimethyl ammonium chloride of 8 parts by weight are added in the reactor and the deionized water of 100 parts by weight is mixed and stirred evenly to form a mixed solution, and the pH value of the mixed solution is adjusted 7.4;

[0056] (2) feed nitrogen into the mixed solution to remove oxygen, and the temperature of the mixed solution is raised to 60° C., under the protection of nitrogen, add the mixed solution of 1 weight part of hydrogen peroxide and ferrous sulfate (wherein: hydrogen peroxide and The weight ratio of ferrous sulfate is 1:1) to react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com