Low-energy-consumption colloid grinder type emulsifying machine

A colloid mill and emulsifying machine technology, applied in the field of emulsifying machine, can solve the problems of wasting heating energy, service life discount, high motor power, etc., and achieve the effects of avoiding leakage, low power consumption, and improving overall sealing and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

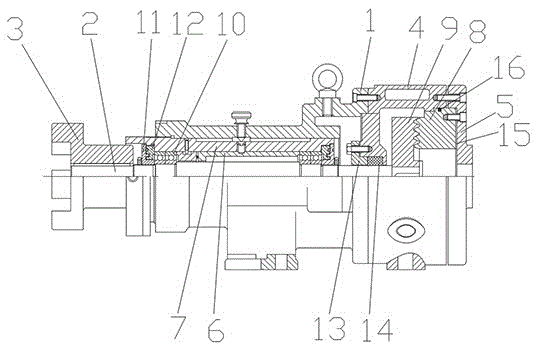

[0021] Such as figure 1 As shown, a low-energy colloid mill emulsifier in this embodiment includes a housing 1, a main shaft 2, a coupling 3, a stator housing 4, an end cover 5, a fixed sleeve 6, a sliding sleeve 7, a stator 8, Rotor 9, bearing 10, sealing cover 11, sealing ring 12, gland 13, packing 14, paper pad 15 and sealing ring 16; the two ends of the stator shell 4 are respectively connected with the shell 1 and the end cover 5, and the shell 1 There is a main shaft 2 inside, which has small overall volume, light weight and low power consumption; the shaft body of the main shaft 2 is sequentially connected with the coupling 3, the bearing 10 and the rotor 9, and the end of the rotor 9 and the stator 8 are equipped with an eight-layer cone. The rotor 9 and the stator 8 mesh with each other through the grinding teeth. Its unique internal tooth design, the eight-layer grinding teeth mesh with each other in a conical shape. When working, the turntable of the colloid mill ro...

Embodiment 2

[0024] Such as figure 1 As shown, a low-energy colloid mill emulsifier in this embodiment includes a housing 1, a main shaft 2, a coupling 3, a stator housing 4, an end cover 5, a fixed sleeve 6, a sliding sleeve 7, a stator 8, Rotor 9, bearing 10, sealing cover 11, sealing ring 12, gland 13, packing 14, paper pad 15 and sealing ring 16; the two ends of the stator shell 4 are respectively connected with the shell 1 and the end cover 5, and the shell 1 There is a main shaft 2 inside, which has small overall volume, light weight and low power consumption; the shaft body of the main shaft 2 is sequentially connected with the coupling 3, the bearing 10 and the rotor 9, and the end of the rotor 9 and the stator 8 are equipped with an eight-layer cone. The rotor 9 and the stator 8 mesh with each other through the grinding teeth. Its unique internal tooth design, the eight-layer grinding teeth mesh with each other in a conical shape. When working, the turntable of the colloid mill ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com