Method for achieving metal-ceramic soldered connections

一种陶瓷焊接、金属焊料的技术,应用在焊接/焊接/切割物品、焊接设备、焊接介质等方向,能够解决高能量消耗、活性焊料充满、不能完全地实现材料连接等问题,达到低焊接温度、高机械负荷能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

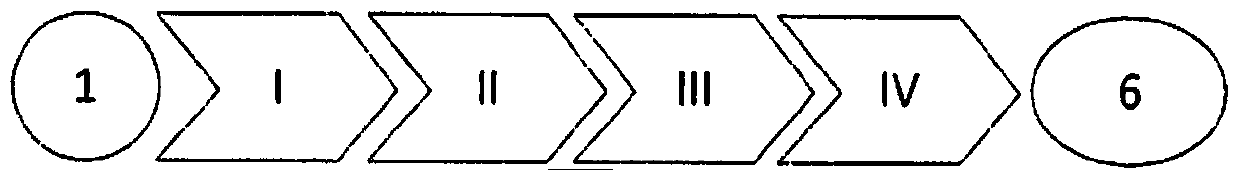

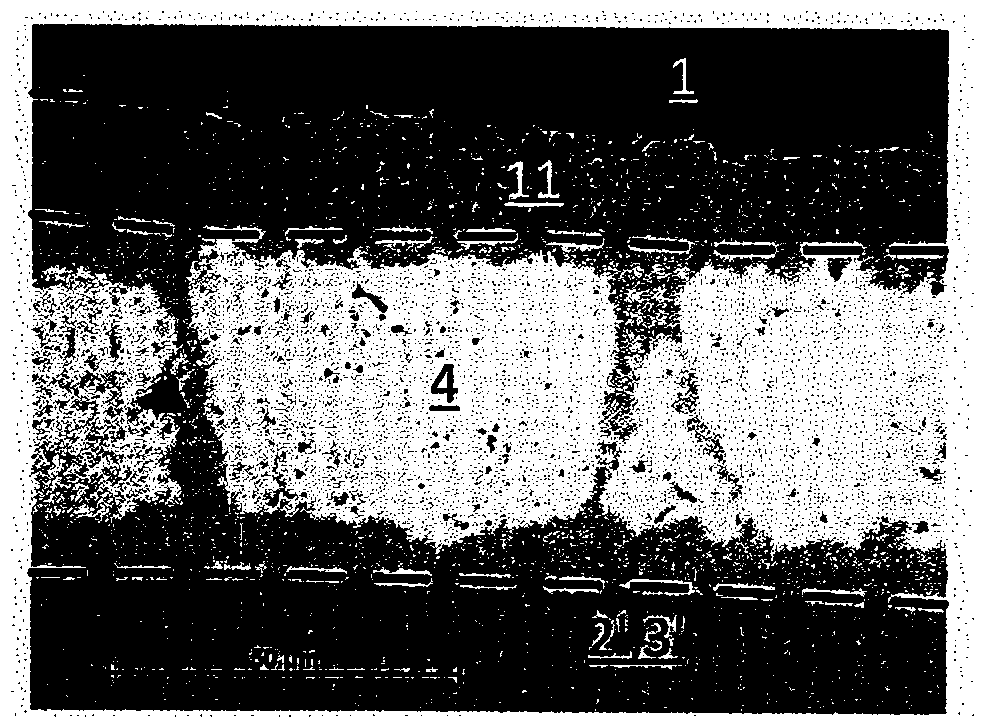

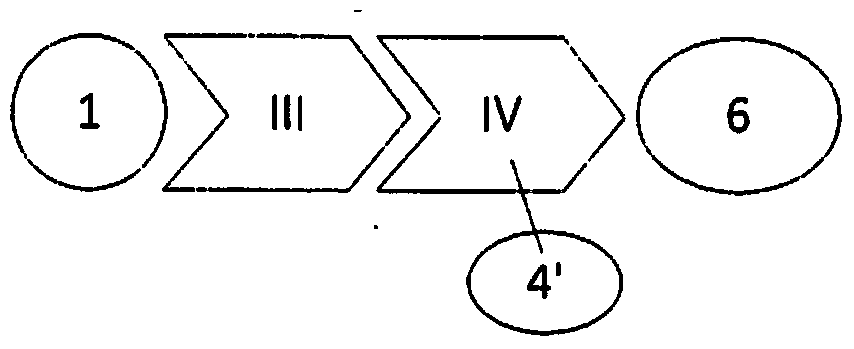

[0035] The following will refer to as Figure 4a-Figure 6 The method according to the invention for producing a material-fit metal-ceramic welded connection is illustrated by the shown ceramic tube 6, which is formed by a material-fit connection of an uncoated ceramic body 1 with metal parts 2, 3. constitute. The coefficients of thermal expansion of the ceramic body 1 and the metal parts 2 , 3 are matched to each other, that is to say similar to each other. At least 80% of the ceramic body 1 should consist of aluminum oxide (sapphire), silicon oxide, zirconium oxide or mixtures thereof. According to the invention, the ceramic body is not coated and accordingly has no metallized and nickel-plated ceramic body surface. This enables the method according to the invention to save working steps compared to similar methods according to the prior art.

[0036] Used as solder 4 is conventional, low cost metal inactive solder. It is important that the solder 4 used is eutectic or cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com