Valve gun for a high-pressure cleaning device

A high-pressure cleaning and valve gun technology, applied in the field of valve guns for high-pressure cleaning equipment, can solve problems such as assembly difficulties, and achieve the effects of low cost, high mechanical load capacity, and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

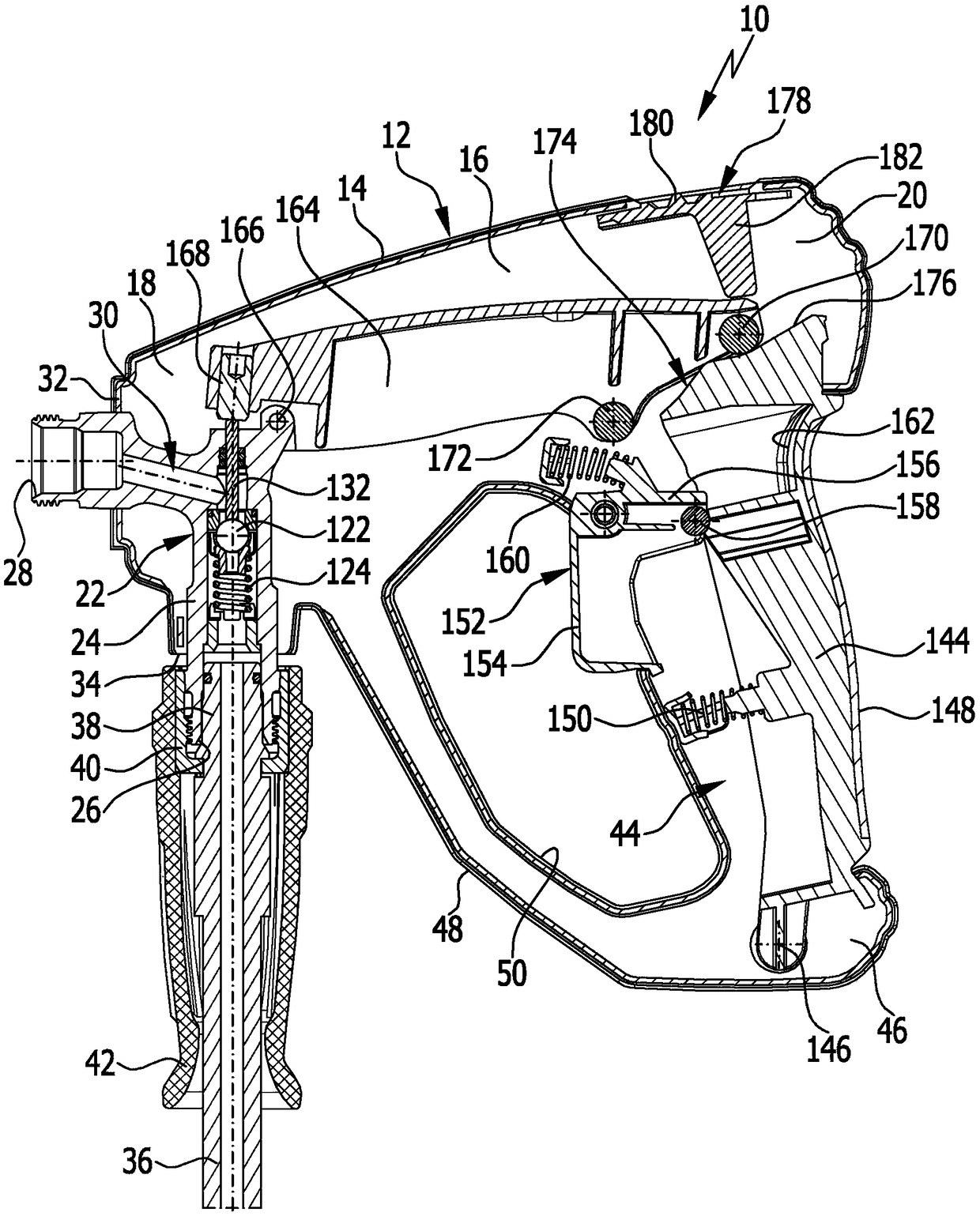

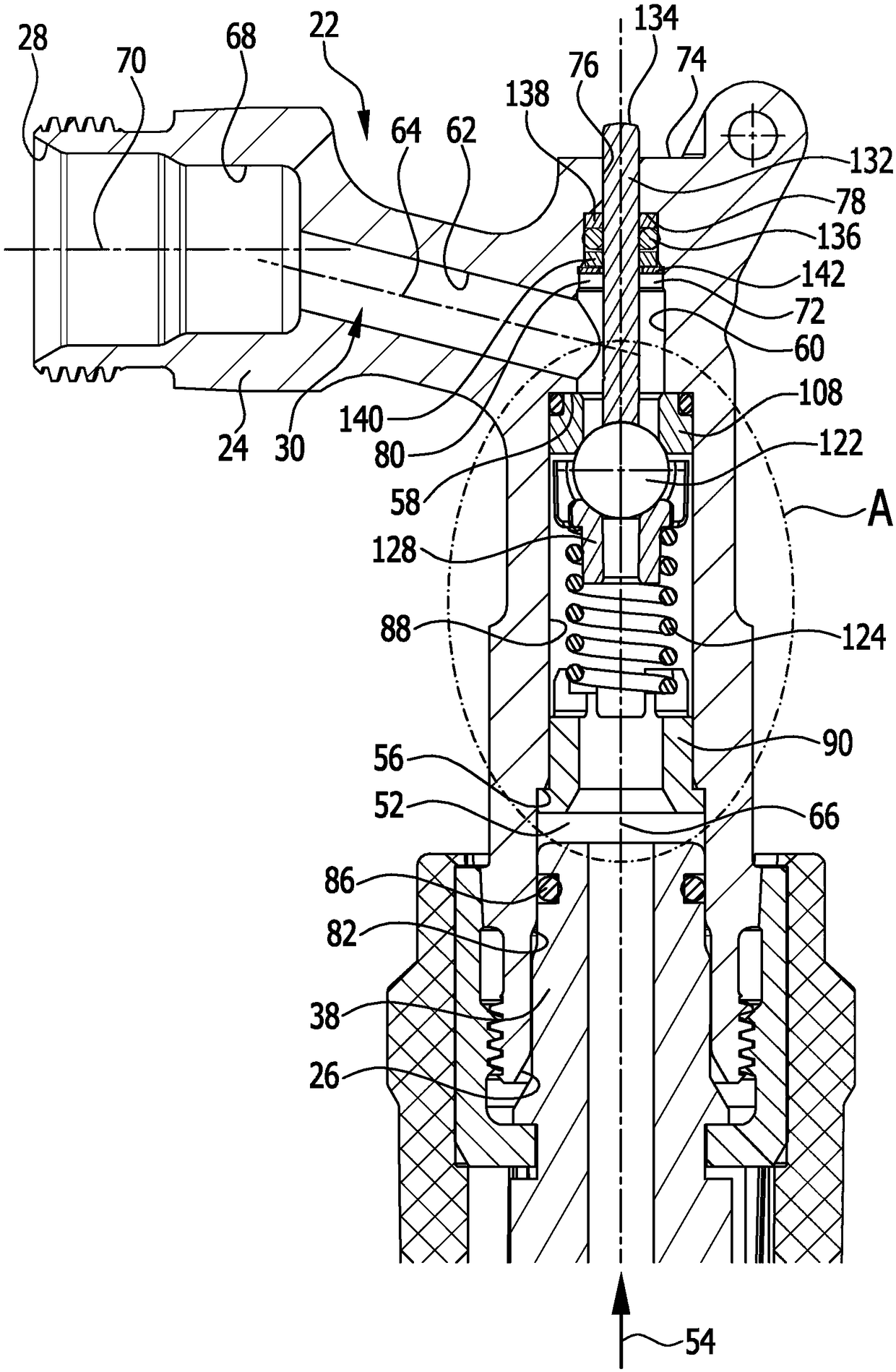

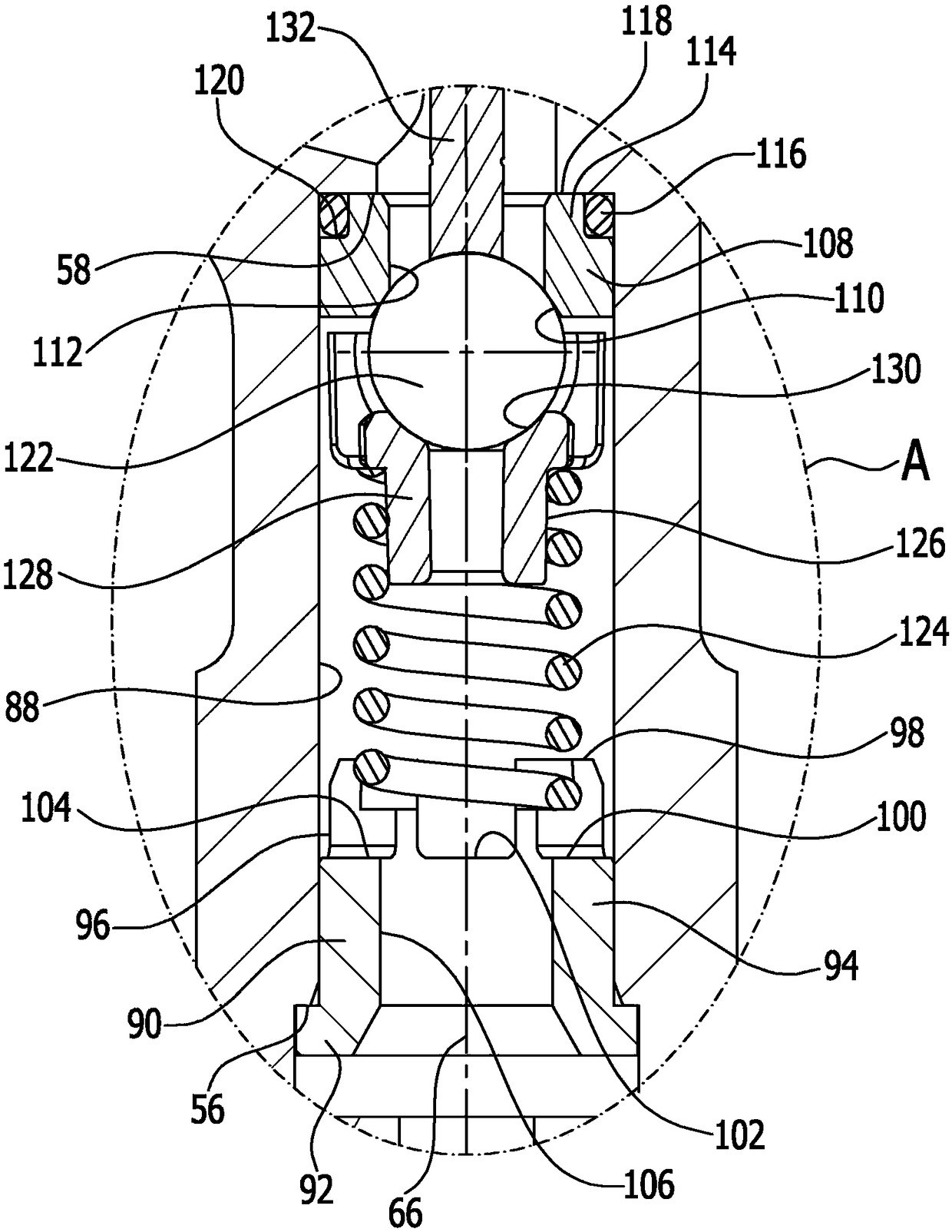

[0041] exist figure 1 An advantageous embodiment of the valve gun according to the invention is schematically shown in FIG. 1 and is assigned the reference numeral 10 as a whole. The valve gun 10 comprises a gun housing 12 which is formed in a conventional manner from a first housing half 14 and a second housing half, not shown in the drawing. The gun housing 12 has a central housing area 16 which is arranged between a front housing area 18 and a rear housing area 20 .

[0042] The front housing region 18 accommodates a valve 22 . The valve 22 has a valve housing 24 with an inlet 26 and an outlet 28 . The inlet 26 is in flow connection with the outlet 28 via a through-channel 30 .

[0043] In the embodiment shown, the outlet 28 protrudes from the front side 32 of the gun housing 12 . A liquid outlet line, for example a spout, can be connected to the outlet 28 . In the embodiment shown, the inlet 26 protrudes from the underside 34 of the gun housing 12 . A liquid feed lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com