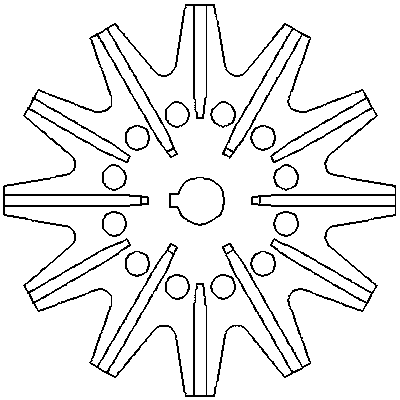

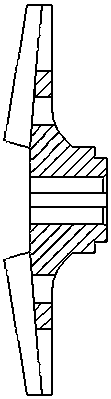

Wear-resistant and corrosion-resistant centrifugal pump impeller coating and its preparation method and application

A centrifugal pump impeller, corrosion-resistant technology, used in coatings, anti-corrosion coatings, wax coatings, etc., can solve the problems of neglecting the combination of different base coatings and surface coatings, weak impact resistance, short corrosion resistance and aging, and achieves the preparation of The technology is easy to master, the service life is prolonged, and the construction is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

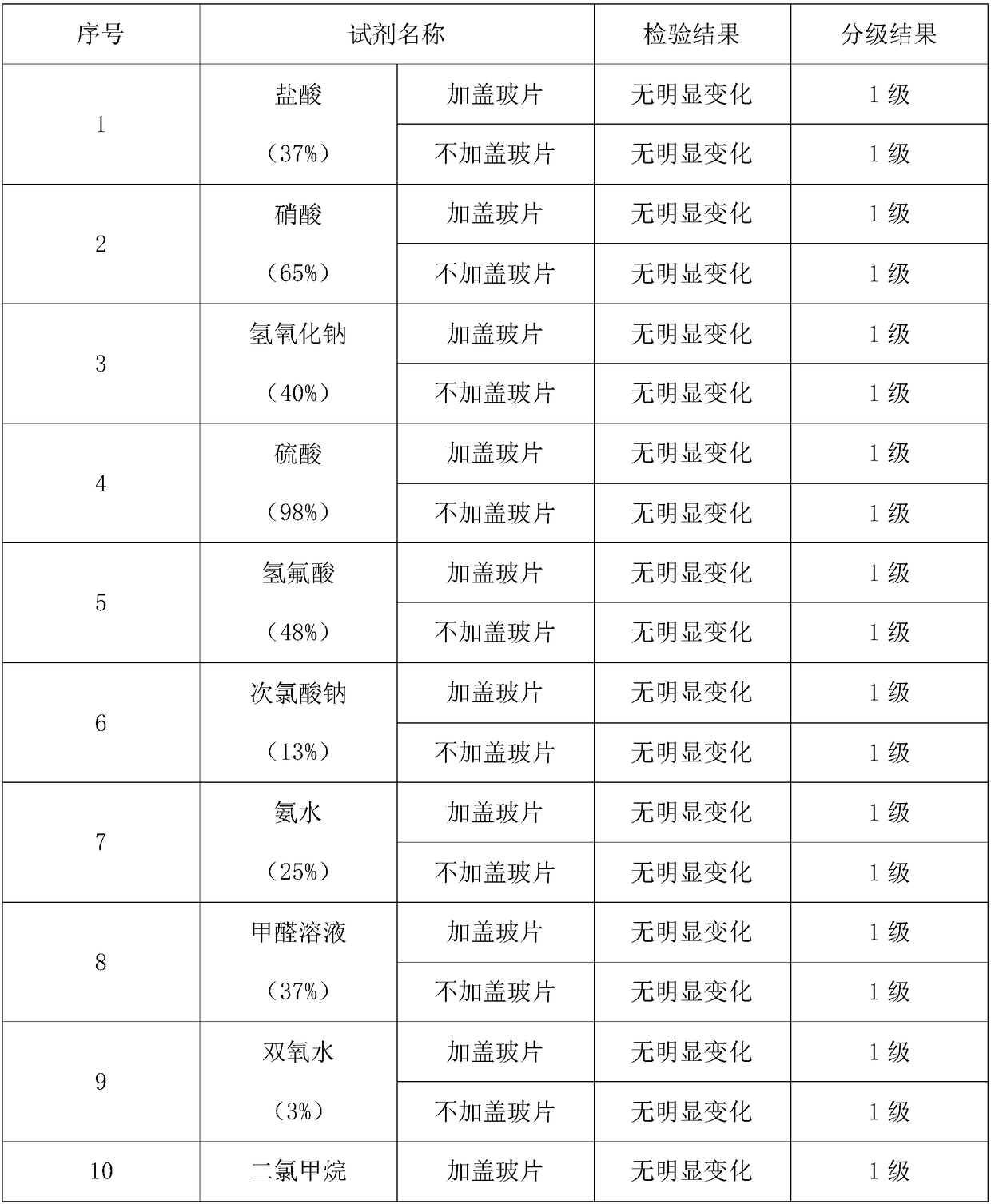

Examples

Embodiment 1

[0019] In the embodiment of the present invention, the wear-resistant and corrosion-resistant centrifugal pump impeller coating includes a base coating and a surface coating, and the base coating is composed of the following raw materials in parts by weight: 11 parts of double fly powder, 3 parts of aluminum oxide, epoxy hard 20 parts of octyl fatty acid, 10 parts of nano-barium sulfate, and 8 parts of dimethylformamide; the surface coating is composed of the following raw materials in parts by weight: 5 parts of silicon dioxide, 3 parts of zirconium silicate, and 18 parts of epoxy resin , 14 parts of chlorinated paraffin, 20 parts of polypropylene resin, and 5 parts of cobalt hydroxide.

[0020] The preparation method of the wear-resistant and corrosion-resistant centrifugal pump impeller coating consists of the following steps:

[0021] The preparation of the base coating: Put the double fly powder, aluminum oxide, epoxy octyl stearate, nano-barium sulfate, dimethylformamide...

Embodiment 2

[0024] In the embodiment of the present invention, the wear-resistant and corrosion-resistant centrifugal pump impeller coating includes a base coating and a surface coating, and the base coating is composed of the following raw materials in parts by weight: 15 parts of double fly powder, 8 parts of aluminum oxide, epoxy hard 27 parts of octyl fatty acid, 16 parts of nano-barium sulfate, and 13 parts of dimethylformamide; the surface coating is composed of the following raw materials in parts by weight: 9 parts of silicon dioxide, 8 parts of zirconium silicate, and 25 parts of epoxy resin , 20 parts of chlorinated paraffin, 27 parts of polypropylene resin, and 10 parts of cobalt hydroxide.

[0025] The preparation method of the wear-resistant and corrosion-resistant centrifugal pump impeller coating consists of the following steps:

[0026] The preparation of the base coating: Put the double fly powder, aluminum oxide, epoxy octyl stearate, nano-barium sulfate, dimethylformami...

Embodiment 3

[0029] In the embodiment of the present invention, the wear-resistant and corrosion-resistant centrifugal pump impeller coating includes a base coating and a surface coating, and the base coating is composed of the following raw materials in parts by weight: 12 parts of double fly powder, 4 parts of aluminum oxide, epoxy hard 22 parts of octyl fatty acid, 12 parts of nano-barium sulfate, and 10 parts of dimethylformamide; the surface coating is composed of the following raw materials in parts by weight: 6 parts of silicon dioxide, 5 parts of zirconium silicate, and 20 parts of epoxy resin , 16 parts of chlorinated paraffin, 22 parts of polypropylene resin, and 6 parts of cobalt hydroxide.

[0030] The preparation method of the wear-resistant and corrosion-resistant centrifugal pump impeller coating consists of the following steps:

[0031] The preparation of the base coating: Put the double fly powder, aluminum oxide, epoxy octyl stearate, nano-barium sulfate, dimethylformamid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com