Organic-inorganic hybrid all-solid-state polymer electrolyte with high thermal resistance and mechanical strength and preparation method thereof

An all-solid polymer, mechanical strength technology, applied in hybrid capacitor electrolytes, capacitor electrolytes/absorbents, electrolytic capacitors, etc., can solve problems such as inability to achieve stable use, achieve easy control, good mechanical properties, and reduce crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

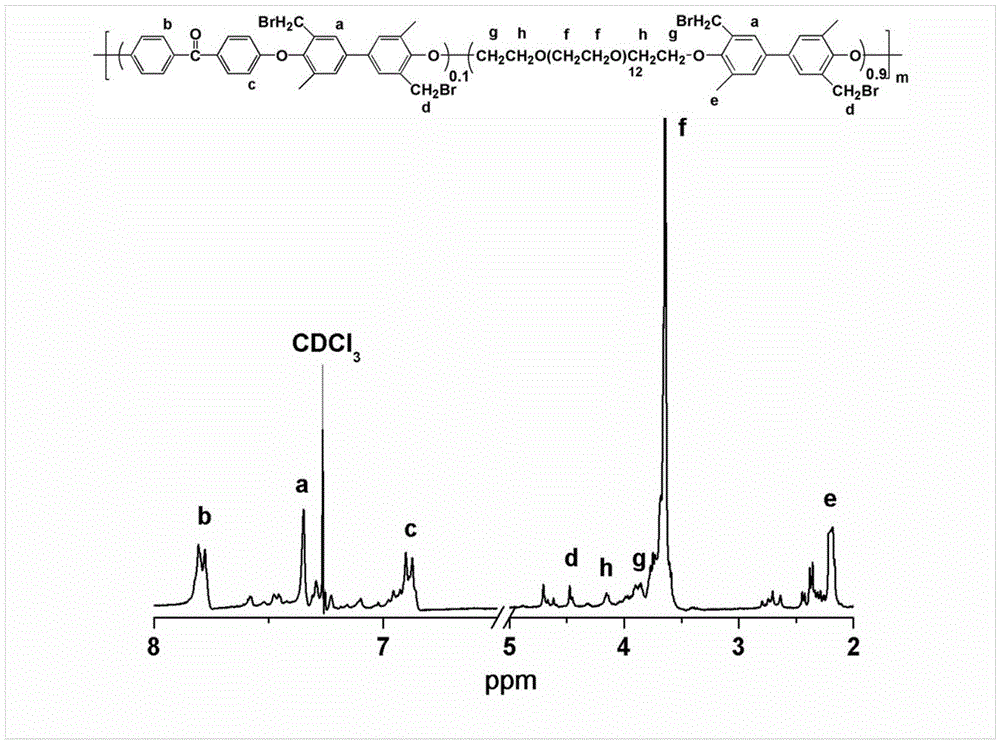

[0029] Example 1: Preparation of polyaryletherketone-polyethylene glycol brominated copolymer PAEK-PEG600-90%-Br.

[0030] 1) Under a nitrogen atmosphere, weigh 15 g of polyethylene glycol with a number-average molecular mass of 600 and add it to a 100 mL three-necked flask, heat to 50 ° C under stirring conditions until the polyethylene glycol melts, and add 15 mL of Chlorothionyl, and then the system was heated to 80 ° C for 6 hours until the reaction was complete, and the reaction device was connected to a vacuum distillation device to remove the remaining thionyl chloride to obtain 15.50 g of chlorine-terminated polyethylene glycol as a pale yellow solid.

[0031] 2) Weigh 3.1420g of 4,4′-difluorobenzophenone, 5.8154g of 3,5,3′,5′-tetramethylbiphenyldiphenol, and chlorine-terminated polyethylene glycol (Mn=600) Add 9.95g, 3.974g of anhydrous potassium carbonate and 50.10mL of reaction solvent sulfolane to a 100mL three-necked flask in sequence, then add 25mL of water-carry...

Embodiment 2

[0036] Example 2: Preparation of polyaryletherketone-polyethylene glycol brominated copolymer PAEK-PEG2000-10%-Br.

[0037] 1) Under a nitrogen atmosphere, weigh 15 g of polyethylene glycol with a number-average molecular mass of 2000 and add it to a 100 mL three-necked flask, heat to 50 ° C under stirring conditions until the polyethylene glycol melts, and add 12 mL of Chlorothionyl, then the system was warmed up to 80 ° C for 6 hours, until the reaction was complete, the reaction device was connected to a vacuum distillation device to remove the remaining thionyl chloride to obtain 15.61 g of chlorine-terminated polyethylene glycol light yellow solid .

[0038] 2) Under a nitrogen atmosphere, weigh 4.7131g of 4,4'-difluorobenzophenone, 2.9762g of 2-methylhydroquinone, 4.8g of chlorine-terminated polyethylene glycol (Mn=2000), Add 3.974g of potassium carbonate water and 50.10mL of reaction solvent sulfolane to the three-necked flask in sequence, then add 25mL of water-carryi...

Embodiment 3

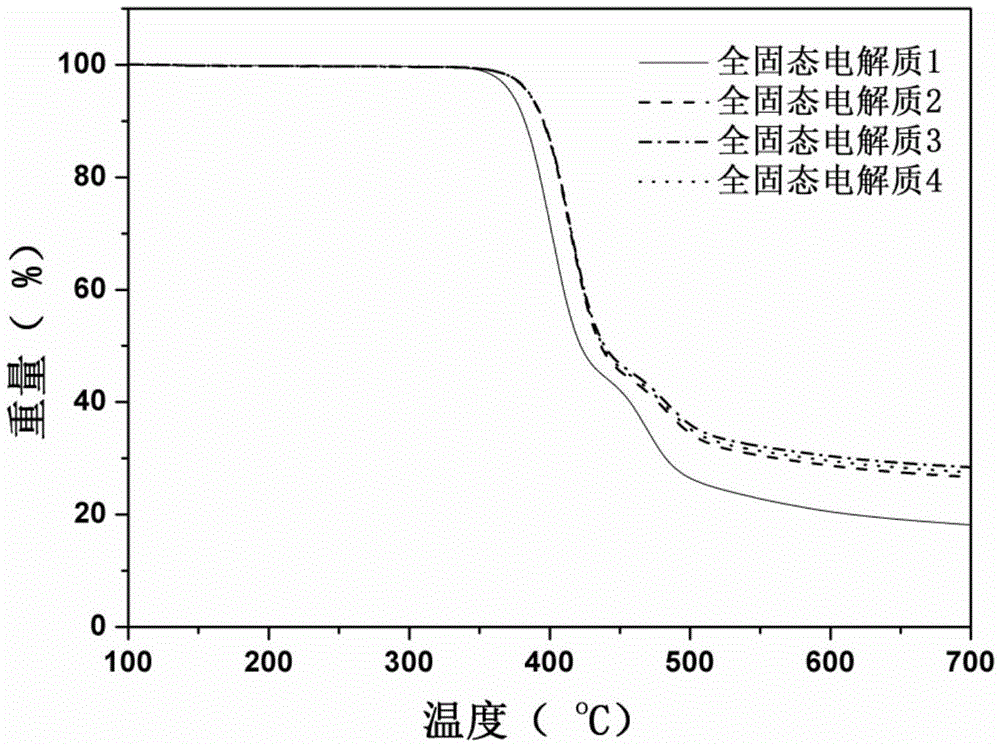

[0043] Example 3: Preparation of polyaryletherketone-polyethylene glycol copolymer all-solid polymer electrolyte 1.

[0044] 1) Dissolve the polyaryletherketone-polyethylene glycol brominated copolymer PAEK-PEG2000-10%-Br0.8g prepared in Example 2 in 8mL of the reaction solvent N,N-dimethylacetamide, at room temperature After stirring for 7 hours, a uniform and transparent mixed solution was obtained.

[0045] 2) Add lithium perchlorate accounting for 30% of the polymer mass into the mixed solution prepared in step (1), stir until it is completely dissolved into a homogeneous solution, and then pour it on a 8×8cm horizontal polytetrafluoroethylene plate to form a The film was vacuum-dried at 80° C. for 72 hours to remove the reaction solvent, and an all-solid polymer electrolyte 1 was obtained.

[0046] This example does not carry out benzyl hydroxylation, and does not add inorganic nanoparticles, and is used as a comparative example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com